When considering the working temperature of a muffle furnace, you must look beyond the simple maximum value. The most critical factors are ensuring the furnace's maximum temperature is slightly higher than your required operating temperature, evaluating its ability to maintain that temperature with high accuracy, and assessing the time it takes to heat up (the rise time). This approach ensures both process success and the long-term health of the equipment.

Choosing a muffle furnace is not just about matching a temperature number to your process. It requires evaluating the entire thermal system—how it heats, holds, and cools—to ensure your results are repeatable, your energy use is efficient, and your investment is durable.

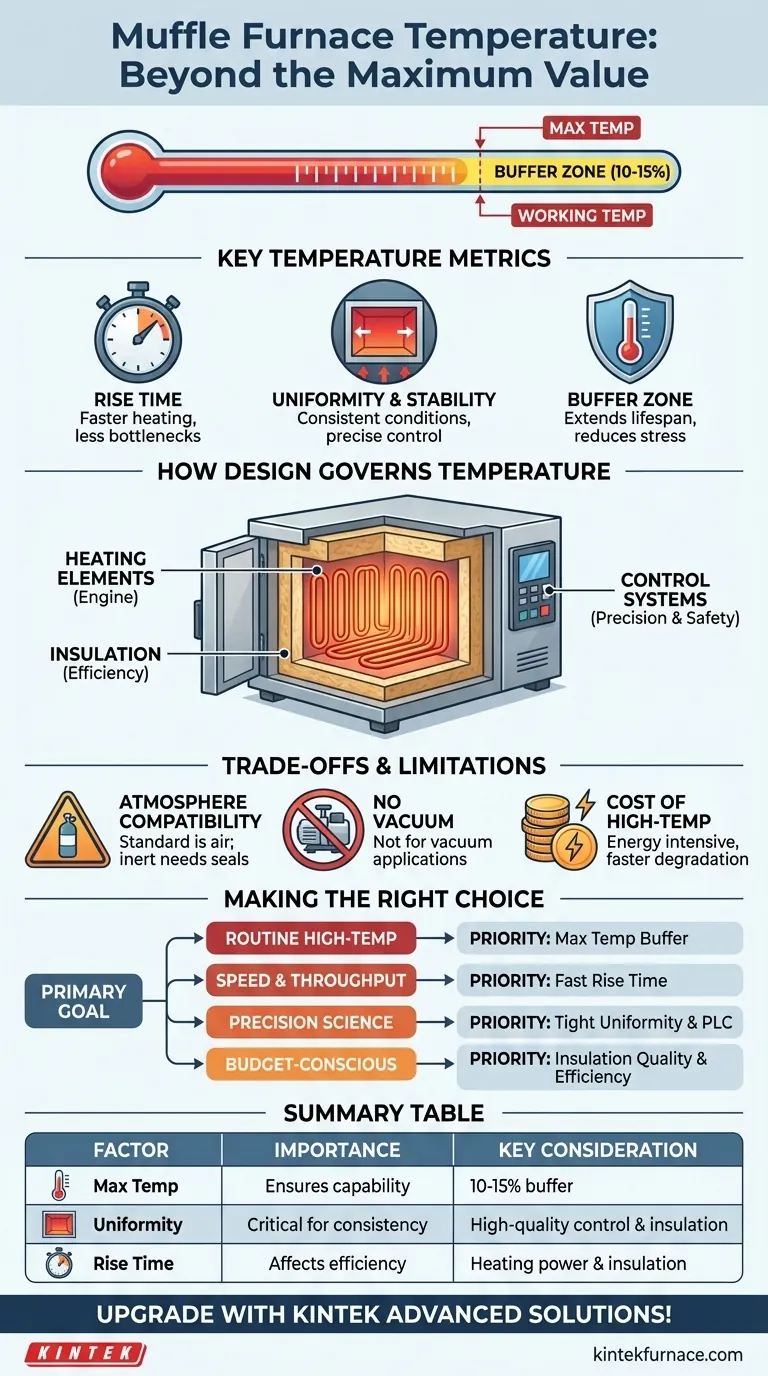

Beyond the Maximum: Key Temperature Metrics

A furnace's temperature specification is more than a single number. To make an informed choice, you must understand the metrics that define its real-world performance.

Defining Your Required Temperature Range

Your specific application—be it ashing, annealing, sintering, or chemical analysis—dictates the necessary temperature range. Ensure the furnace comfortably meets both the minimum and maximum temperatures your process requires.

The "Buffer Zone" Principle

A crucial best practice is to select a furnace with a maximum temperature that exceeds your typical working temperature. Operating a furnace consistently at its absolute limit puts extreme stress on heating elements and insulation, leading to premature failure.

A buffer of 10-15% provides flexibility and dramatically extends the equipment's lifespan.

Rise Time and Heating Rate

Rise time is the time the furnace takes to reach its maximum temperature. A slow rise time can create significant bottlenecks in a lab or production environment, wasting both time and energy.

This metric is directly influenced by the power of the heating elements and the quality of the insulation.

Temperature Uniformity and Stability

The furnace must not only reach a setpoint but hold it with precision across the entire chamber. Temperature uniformity ensures your entire sample is exposed to the same thermal conditions.

High-quality temperature controllers, such as digital or PLC-based systems, are essential for maintaining stable temperatures with minimal fluctuation, which is critical for sensitive processes.

How Furnace Design Governs Temperature

The physical construction of the furnace is what enables its temperature performance. Understanding these components helps you assess a model's quality and suitability.

Heating Elements: The Engine of the Furnace

Heating elements are the heart of the furnace. Their material composition (e.g., Kanthal wire, silicon carbide) determines the furnace's maximum achievable temperature and its durability under thermal cycling. High-quality elements deliver more uniform heating and a longer service life.

Insulation: The Key to Efficiency

Effective insulation, typically made of refractory brick or ceramic fiber, is what allows a furnace to reach and maintain high temperatures efficiently.

Poor insulation leads to significant heat loss, forcing the heating elements to work harder, increasing energy consumption, and compromising temperature stability.

Control Systems and Safety

Modern furnaces use sophisticated controllers to manage thermal profiles, including multi-step ramps and soaks. These software features allow for highly repeatable and complex processes.

Crucially, these systems also incorporate safety features like over-temperature protection, which automatically shuts down the furnace to prevent damage and ensure operator safety.

Understanding the Trade-offs and Limitations

No single tool is perfect for every job. A muffle furnace's temperature capabilities come with inherent limitations you must consider.

Atmosphere Compatibility

A furnace's high temperature rating is only useful if it's compatible with your required processing atmosphere. Standard muffle furnaces operate in air. If your process requires an inert gas like nitrogen or argon, you must ensure the furnace has the necessary gas-tight seals and inlet/outlet ports.

The Inability to Hold a Vacuum

Muffle furnaces are designed for operation at atmospheric pressure. They are not suitable for applications requiring a vacuum.

For processes like degassing or sintering highly sensitive materials that must be free from atmospheric contamination, a dedicated vacuum furnace is the correct choice.

The Cost of High-Temperature Operation

Running a furnace at or near its maximum temperature is extremely energy-intensive. Furthermore, it accelerates the degradation of all components, especially heating elements and thermocouples. Factoring in energy consumption and future maintenance is a critical part of the total cost of ownership.

Making the Right Choice for Your Goal

Select your furnace by aligning its thermal performance characteristics with your primary objective.

- If your primary focus is routine, high-temperature processing (e.g., ashing): Prioritize a furnace with a maximum temperature well above your working setpoint to ensure long-term durability.

- If your primary focus is process speed and throughput: Focus on a fast rise time and a programmable controller that can execute rapid, repeatable thermal cycles.

- If your primary focus is precision material science: Emphasize tight temperature uniformity specifications and a sophisticated PLC controller for creating complex, accurate thermal profiles.

- If your primary focus is budget-conscious operation: Pay close attention to insulation quality and the furnace's overall energy efficiency to minimize long-term running costs.

Thinking beyond the peak temperature to the entire thermal system ensures you invest in a tool that is not just capable, but reliable and efficient for years to come.

Summary Table:

| Factor | Importance | Key Considerations |

|---|---|---|

| Maximum Temperature | Ensures process capability | Select furnace with 10-15% buffer above working temperature to prevent stress and extend lifespan |

| Temperature Uniformity | Critical for sample consistency | Requires high-quality controllers and insulation for even heating across the chamber |

| Rise Time | Affects efficiency and throughput | Influenced by heating element power and insulation; faster times reduce bottlenecks |

| Atmosphere Compatibility | Determines process suitability | Standard furnaces operate in air; inert gases need gas-tight seals |

| Control Systems | Enables repeatability and safety | Digital or PLC controllers with over-temperature protection for precise thermal profiles |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency, durability, and results. Contact us today to discuss how we can optimize your thermal processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating