At their core, muffle furnaces are constructed from a strategic combination of materials chosen for extreme heat resistance and chemical inertness. The primary components are a durable steel outer shell, high-performance ceramic or alumina fiber insulation, a protective inner ceramic chamber (the muffle), and specialized high-temperature heating elements. Each material is selected to perform a critical function in a high-stress environment.

The selection of materials in a muffle furnace is not about a single "best" substance, but about an engineered system. The goal is to balance structural durability on the outside, maximum thermal containment in the middle, and chemical stability on the inside, all while delivering precise heat.

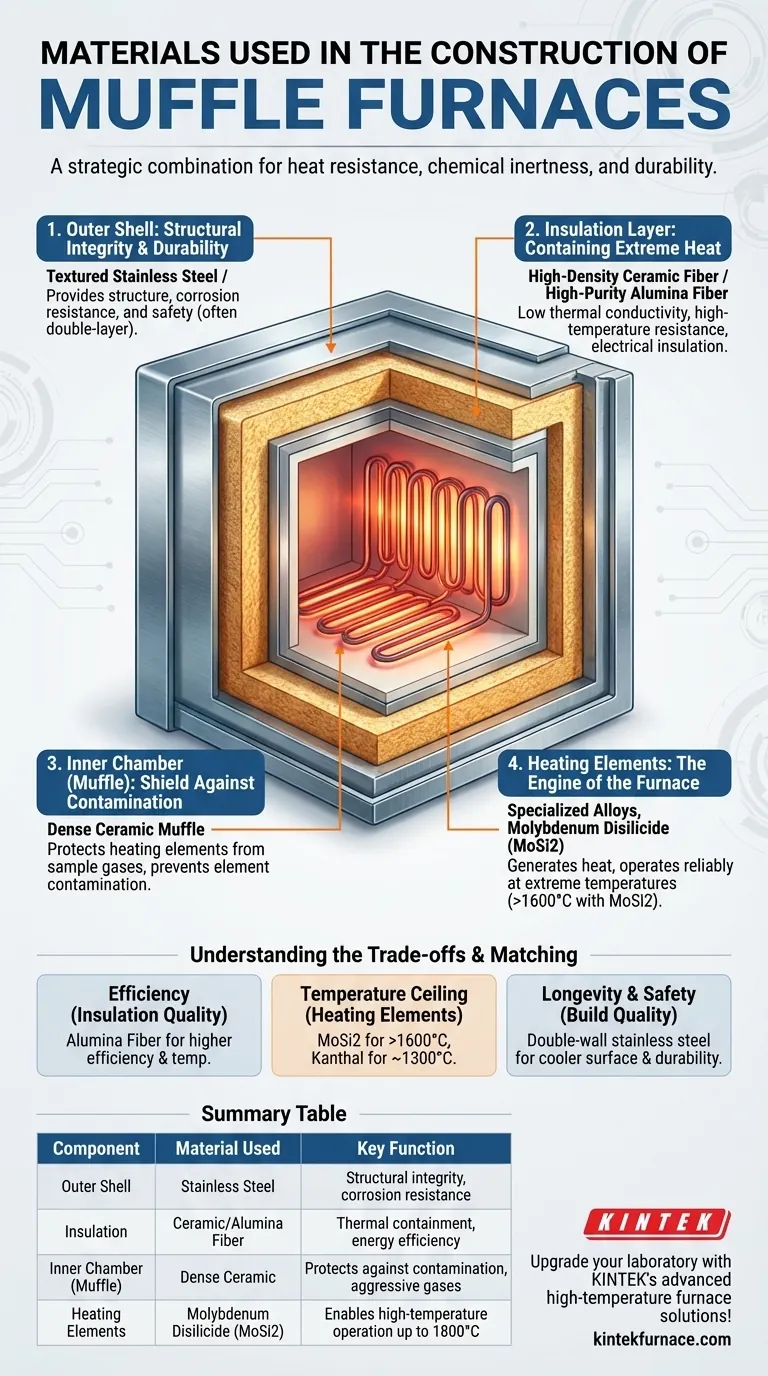

The Anatomy of a Muffle Furnace: A Material-by-Material Breakdown

To understand a furnace's performance, you must first understand the role of its constituent parts. Each material is chosen to solve a specific engineering challenge presented by sustained, high-temperature operation.

The Outer Shell: Structural Integrity and Durability

The external housing provides the furnace's structure and first line of defense. It is typically built from textured stainless steel or a similar rugged steel shell.

This choice prioritizes durability and corrosion resistance, ensuring the furnace can withstand the rigors of a lab or industrial environment. Some designs feature a double-layer shell, which helps reduce the external surface temperature and improves overall energy efficiency.

The Insulation Layer: Containing Extreme Heat

The most critical material for performance and efficiency is the insulation packed between the outer shell and the inner chamber. This is not simple fiberglass; it is a high-performance thermal barrier.

The most common materials are high-density ceramic fiber and high-purity alumina fiber. Alumina fiber is particularly valued for its exceptional properties:

- Low thermal conductivity, meaning it is extremely effective at preventing heat from escaping.

- High temperature resistance, with some grades usable up to 1700°C (3092°F).

- Good electrical insulation, which is vital for safety when surrounding electric heating elements.

Advanced furnaces use a graded insulation package, layering different materials to optimize thermal containment across a range of temperatures.

The Inner Chamber (Muffle): A Shield Against Contamination

The "muffle" itself is the sealed inner chamber that contains the sample. It is almost always made of a dense ceramic material.

The purpose of the ceramic muffle is twofold. First, it protects the electric heating elements from any aggressive gases or vapors released by the sample during heating. Second, it prevents contaminants from the heating elements (like dust or oxidized particles) from falling onto the sample, ensuring a clean processing environment.

The Heating Elements: The Engine of the Furnace

The elements that generate the heat are made from specialized alloys designed to operate reliably at extreme temperatures.

While the specific alloy varies by the furnace's temperature rating, high-performance models capable of reaching over 1600°C often use molybdenum disilicide (MoSi2) elements. These are superior to more common metallic elements in their ability to withstand repeated heating cycles to very high temperatures without degrading quickly.

Understanding the Trade-offs

The quality and type of materials used directly translate to the furnace's performance, lifespan, and cost. Understanding these differences is key to evaluating a unit's true capabilities.

Insulation Quality Dictates Efficiency

A furnace insulated with standard ceramic fiber is effective for many applications, but one using high-purity alumina fiber will generally be more energy-efficient and capable of reaching higher, more stable temperatures. This superior performance, however, comes at a higher initial cost.

Heating Elements Define the Temperature Ceiling

The furnace's maximum achievable temperature is dictated entirely by its heating elements. A furnace with standard Kanthal (FeCrAl) elements may be limited to 1200-1300°C, while one with molybdenum disilicide (MoSi2) elements can reliably operate at 1700-1800°C. Choosing a furnace with elements underrated for your needs will lead to premature failure.

Build Quality Impacts Longevity and Safety

A simple, single-wall steel shell is functional, but a double-wall, stainless steel construction provides better corrosion resistance and a cooler external surface, which is a critical safety feature for operators. The quality of the construction directly impacts the furnace's longevity.

Matching Materials to Your Application

Choosing the right furnace means aligning its material composition with your specific requirements for temperature, atmosphere, and longevity.

- If your primary focus is reaching ultra-high temperatures (above 1600°C): You must select a furnace with molybdenum disilicide (MoSi2) heating elements and high-purity alumina fiber insulation.

- If your primary focus is general-purpose ashing or heat-treating: A model with a stainless steel body, quality ceramic fiber insulation, and a durable ceramic muffle is the reliable workhorse for most labs.

- If your primary focus is process purity and preventing contamination: Ensure the furnace has a fully sealed, high-density ceramic muffle to isolate your samples from the heating elements.

Understanding these core materials empowers you to select a furnace that is not just a tool, but a reliable and precise instrument for your work.

Summary Table:

| Component | Material Used | Key Function |

|---|---|---|

| Outer Shell | Stainless Steel | Provides structural integrity and corrosion resistance |

| Insulation | Ceramic/Alumina Fiber | Ensures thermal containment and energy efficiency |

| Inner Chamber (Muffle) | Dense Ceramic | Protects against contamination and aggressive gases |

| Heating Elements | Molybdenum Disilicide (MoSi2) | Enables high-temperature operation up to 1800°C |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for enhanced efficiency and performance. Contact us today to discuss how we can support your high-temperature applications!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control

- How does a stainless steel reactor function within a muffle furnace for PET to graphene? Master Carbon Synthesis

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis