Above all else, never introduce liquids, oils, or other volatile substances into a muffle furnace. Safe and effective operation hinges on avoiding a few critical actions: never overload the chamber, leave the door ajar during a high-temperature cycle, use containers not rated for the heat, or bypass built-in safety mechanisms. These rules exist to prevent explosive pressure buildup, catastrophic equipment failure, and severe personal injury.

A muffle furnace is a precision instrument that demands respect for thermal and atmospheric stability. The most dangerous operational errors stem from introducing sudden, uncontrolled changes—such as liquids causing pressure spikes, an open door causing thermal shock, or reactive materials creating a hazardous environment.

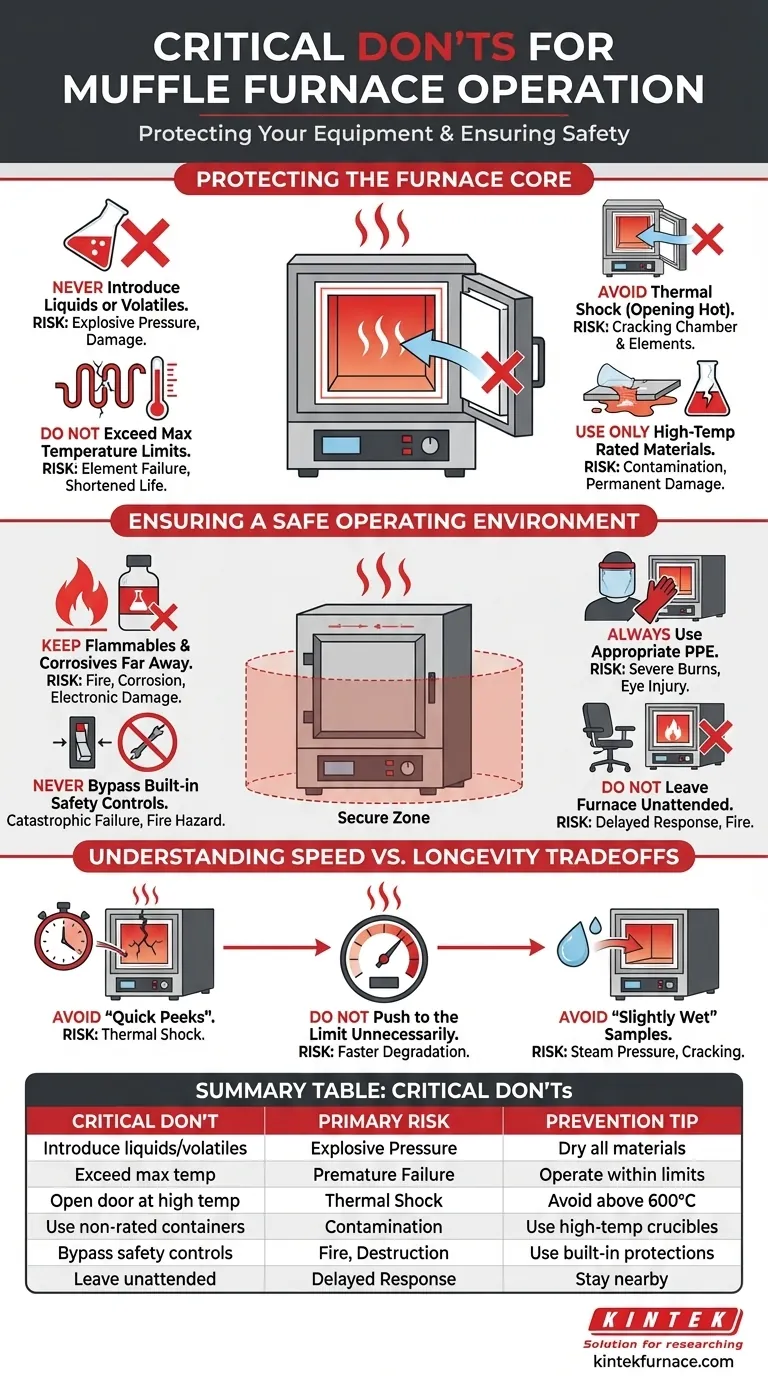

Protecting the Furnace Core: The Chamber and Elements

The heart of the muffle furnace is its insulated chamber and heating elements. These components are powerful but also surprisingly fragile. Most critical errors directly threaten their integrity.

Never Introduce Liquids or Volatiles

Any liquid—water, solvents, or oils—vaporizes with explosive force at high temperatures. This rapid expansion can create a pressure spike that damages the furnace door, cracks the insulation, or even causes a dangerous blowout.

Even samples that appear dry can hold moisture. Ensure all materials and tools (like tongs) are completely dry before they enter the chamber.

Do Not Exceed Maximum Temperature Limits

Every furnace has a maximum rated temperature. Exceeding it, even for a short time, will drastically shorten the life of the heating elements and insulation.

Similarly, avoid operating the furnace continuously at its absolute maximum rated temperature. This places immense stress on the components and is a primary cause of premature failure.

Avoid Thermal Shock at All Costs

The refractory materials lining the furnace are ceramic-based and can crack when subjected to rapid temperature changes.

Never open the furnace door when the temperature is extremely high (a common guideline is to avoid opening above 600°C). The rush of cool air can cause immediate, irreversible damage to the heating elements and chamber lining.

Use Only High-Temperature Rated Materials

Place your samples in crucibles or on trays specifically designed for the temperatures you intend to reach.

Standard glassware, plastics, or low-grade metals will melt, shatter, or release fumes, contaminating your sample and permanently damaging the furnace floor and walls.

Ensuring a Safe Operating Environment

A furnace's high energy output makes the surrounding area part of the safety equation. A mistake made outside the furnace can be just as dangerous as one made inside.

Keep Flammables and Corrosives Far Away

The furnace's exterior surfaces become extremely hot. Maintain a clear zone around the unit, completely free of flammable materials like solvents, paper, or combustible chemicals.

Corrosive substances should also be kept separate, as their fumes can damage the furnace's electronics and metal casing over time.

Never Bypass Built-in Safety Controls

Modern furnaces include safety features like over-temperature protection and automatic shut-offs. These are your last line of defense against catastrophic failure.

Disabling or ignoring these controls is a reckless act that exposes you and your lab to extreme risk of fire or equipment destruction.

Always Use Appropriate Personal Protective Equipment (PPE)

Operating a muffle furnace without proper PPE is non-negotiable.

Heat-resistant gloves are essential for handling the door or removing samples. Safety glasses or a face shield protect against heat radiation and potential projectiles in the rare event of a material failure inside the furnace.

Do Not Leave the Furnace Unattended

While running a long, automated cycle, it is critical to remain in the general vicinity.

If an abnormality occurs—such as an unexpected temperature spike or unusual noise—you must be present to perform an emergency shutdown. An unattended furnace in a failure state is a significant fire hazard.

Understanding the Trade-offs: Speed vs. Longevity

Many operational "don'ts" are violated in an attempt to save time. This is always a poor trade-off that sacrifices equipment life and safety for a few minutes of convenience.

The Fallacy of "Quick Peeks"

The temptation to briefly open the door to check on a sample is strong but misguided. Each "quick peek" introduces a wave of thermal shock that stresses the entire system. Trust your temperature controller and your process timing.

The Risk of Pushing to the Limit

Running a furnace at 1100°C when a process only requires 1050°C does not make it work "better." It only serves to degrade the heating elements faster, leading to more frequent and costly replacements.

The Danger of "Slightly Wet" Samples

Drying a sample inside the furnace seems efficient, but the risk is not worth it. The time you save by not pre-drying a sample is insignificant compared to the cost of replacing a chamber cracked by a steam pressure event.

A Final Check Before You Begin

Before starting any heating cycle, run through a mental checklist of these critical rules. Your goal should be to create a stable, controlled, and predictable environment.

- If your primary focus is operator safety: Prioritize avoiding all liquids and always using proper PPE, as these steps prevent the most immediate and severe personal injuries.

- If your primary focus is equipment longevity: Concentrate on preventing thermal shock by minimizing door openings and avoiding prolonged operation at the absolute maximum temperature.

- If your primary focus is process accuracy: Ensure you use appropriate, clean crucibles and avoid overloading the chamber to guarantee even heat distribution and prevent sample contamination.

By treating the furnace as a precision instrument rather than a simple oven, you ensure safe, repeatable, and effective results every time.

Summary Table:

| Critical Don't | Primary Risk | Prevention Tip |

|---|---|---|

| Introduce liquids or volatiles | Explosive pressure buildup, damage | Ensure all materials are completely dry |

| Exceed max temperature limits | Premature element failure | Operate within rated limits |

| Open door at high temperatures | Thermal shock, cracking | Avoid opening above 600°C |

| Use non-rated containers | Contamination, furnace damage | Use high-temperature crucibles |

| Bypass safety controls | Fire, equipment destruction | Always use built-in protections |

| Leave furnace unattended | Delayed response to failures | Stay nearby during operation |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can enhance your operations with tailored furnace solutions!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?