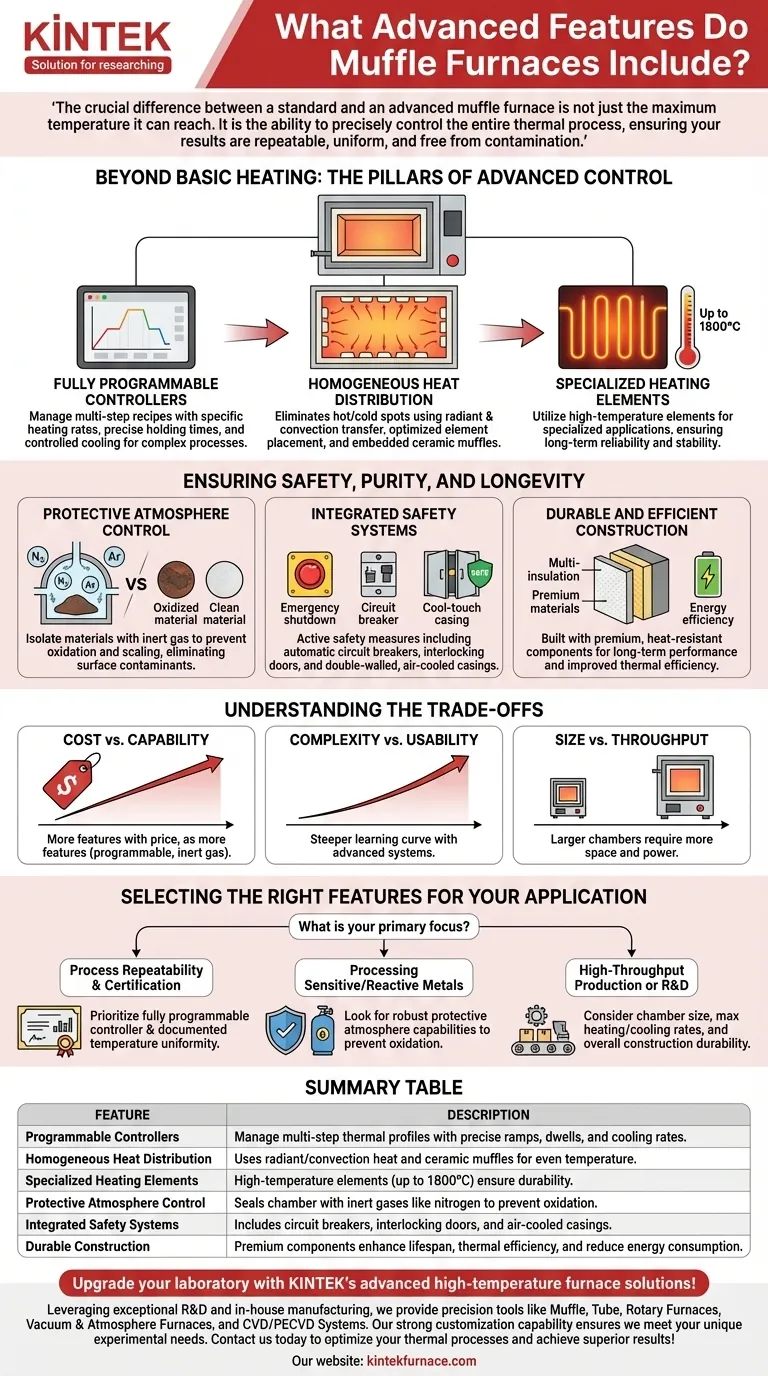

At their core, advanced muffle furnaces move beyond simple heating to offer precise process control, enhanced safety, and superior material outcomes. Key advanced features include fully programmable temperature controllers for multi-step cycles, specialized heating elements and chamber designs that ensure homogeneous heat distribution, and integrated systems for protective atmospheres and operator safety.

The crucial difference between a standard and an advanced muffle furnace is not just the maximum temperature it can reach. It is the ability to precisely control the entire thermal process, ensuring your results are repeatable, uniform, and free from contamination.

Beyond Basic Heating: The Pillars of Advanced Control

The value of an advanced muffle furnace lies in its ability to execute a thermal process exactly as designed, every single time. This is achieved through a combination of sophisticated control, heating, and design features.

Fully Programmable Controllers

A basic furnace may have a simple temperature setting. Advanced models feature fully programmable controllers that manage the entire thermal profile.

This allows you to define multi-step recipes with specific heating rates (ramps), precise holding times (dwells), and controlled cooling rates. This level of control is essential for complex metallurgical, ceramic, or chemical processes.

Homogeneous Heat Distribution

Ensuring the workpiece is heated evenly is critical for consistent results. Advanced furnaces use specific designs to eliminate hot or cold spots within the chamber.

This is often achieved through a combination of radiant and convection heat transfer, optimized placement of heating elements, and the use of embedded ceramic muffles that diffuse heat evenly. The goal is temperature uniformity across the entire processing volume.

Specialized Heating Elements

The type and quality of heating elements dictate the furnace's performance ceiling. Advanced furnaces utilize high-temperature electric heating elements capable of reaching up to 1800°C for specialized applications.

These elements are chosen not just for their heat output but also for their durability and stability over thousands of hours, ensuring long-term reliability.

Ensuring Safety, Purity, and Longevity

Advanced features also address the practical realities of operating high-temperature equipment safely and efficiently while protecting the materials being processed.

Protective Atmosphere Control

Many materials react negatively with oxygen at high temperatures, leading to oxidation and scaling. A key advanced feature is the ability to isolate materials from contaminants.

This is done by creating a protective atmosphere. The furnace chamber is sealed and purged with an inert gas like nitrogen or argon, displacing the air and preventing unwanted chemical reactions on the workpiece surface.

Integrated Safety Systems

Operator safety is paramount. Advanced furnaces move beyond simple insulation to include active safety measures.

Features like automatic circuit breakers for emergency shutdowns, interlocking doors that prevent opening at high temperatures, and double-walled, air-cooled casings keep external surfaces safe to the touch.

Durable and Efficient Construction

An advanced furnace is built for long-term performance. This involves using premium, heat-resistant components and an extra-sturdy construction.

This focus on quality not only increases the furnace's lifespan but also improves thermal efficiency, reducing heat loss and lowering energy consumption over time.

Understanding the Trade-offs

Selecting advanced features requires a clear understanding of the compromises involved. More capability often introduces complexity and cost.

Cost vs. Capability

There is a direct correlation between the sophistication of features and the price of the furnace. A unit with programmable controls and inert gas capabilities will be significantly more expensive than a basic furnace. It is critical to match the features to the actual application requirements to avoid over-investing.

Complexity vs. Usability

Advanced features, particularly programmable controllers and gas management systems, introduce a steeper learning curve for operators. They may also require more complex maintenance and calibration routines compared to simpler models.

Size vs. Throughput

The references note that furnaces come in sizes from small benchtop units to large industrial models. While a larger chamber allows for higher throughput, it also demands more physical space, greater power infrastructure, and has a higher initial cost.

Selecting the Right Features for Your Application

Your choice should be guided by your end goal. Use this framework to prioritize the features that will deliver the most value for your work.

- If your primary focus is process repeatability and certification: Prioritize a furnace with a fully programmable controller and documented temperature uniformity.

- If your primary focus is processing sensitive or reactive metals: Look for a model with robust protective atmosphere capabilities to prevent oxidation.

- If your primary focus is high-throughput production or R&D: Consider the chamber size, maximum heating/cooling rates, and overall construction durability to ensure it can withstand demanding cycles.

Ultimately, the best muffle furnace is the one whose features directly solve your specific material processing challenges.

Summary Table:

| Feature | Description |

|---|---|

| Programmable Controllers | Manage multi-step thermal profiles with precise ramps, dwells, and cooling rates for repeatable processes. |

| Homogeneous Heat Distribution | Uses radiant/convection heat and ceramic muffles for even temperature across the chamber. |

| Specialized Heating Elements | High-temperature elements (up to 1800°C) ensure durability and stable performance. |

| Protective Atmosphere Control | Seals chamber with inert gases like nitrogen to prevent oxidation and contamination. |

| Integrated Safety Systems | Includes circuit breakers, interlocking doors, and air-cooled casings for operator protection. |

| Durable Construction | Premium components enhance lifespan, thermal efficiency, and reduce energy consumption. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, delivering reliable performance and enhanced safety. Contact us today to discuss how we can optimize your thermal processes and achieve superior results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production