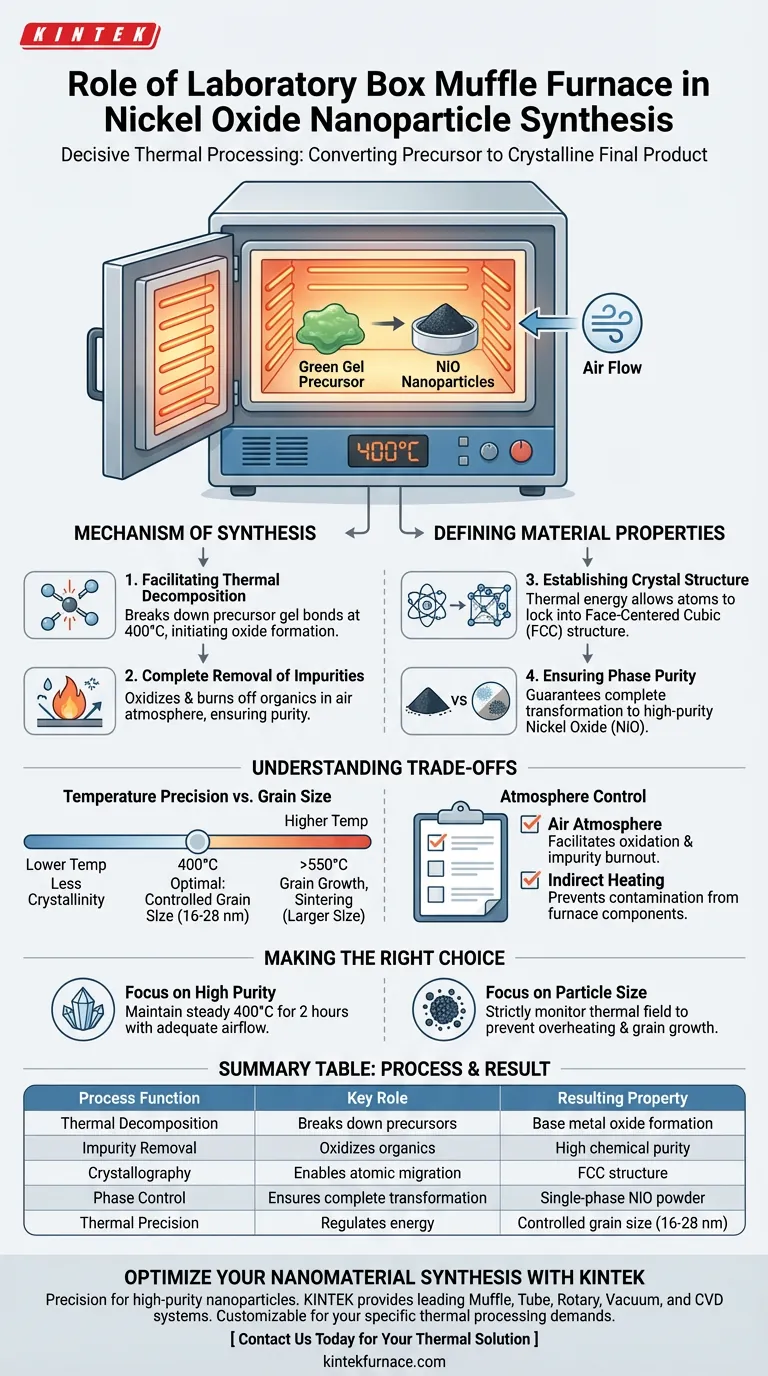

A laboratory box muffle furnace serves as the decisive thermal processing unit in the creation of Nickel Oxide nanoparticles, specifically executing the critical calcination phase. By maintaining a consistent 400°C environment in an air atmosphere for approximately two hours, the furnace converts a precursor "green gel" into a thermally stable, crystalline final product.

Core Takeaway The muffle furnace is not merely a heater; it is a reaction chamber that drives chemical purity and structural order. Its primary function is to eliminate organic contaminants and force the atomic lattice to arrange into a specific face-centered cubic structure, determining the material’s final quality.

The Mechanism of Synthesis

Facilitating Thermal Decomposition

The synthesis begins with a precursor material, often described as a green gel.

The muffle furnace provides the energy required to thermally decompose this precursor. At 400°C, the chemical bonds holding the gel together break down, initiating the transformation into a metal oxide.

Complete Removal of Impurities

During the precursor preparation, various organic compounds and volatiles are trapped within the material.

The furnace acts as a purification tool. By sustaining high heat in an air atmosphere, it oxidizes and burns off these organic impurities, ensuring they do not contaminate the final nanoparticle powder.

Defining Material Properties

Establishing Crystal Structure

The most critical role of the furnace is determining the crystallography of the nanoparticle.

The thermal energy supplied allows atoms to migrate and lock into a stable configuration. In the case of Nickel Oxide, this results in a specific face-centered cubic (FCC) crystal structure.

Ensuring Phase Purity

Without precise temperature application, the material might remain a mixture of hydroxides and oxides.

The box muffle furnace ensures the phase transformation is complete. It guarantees that the resulting powder is high-purity Nickel Oxide, rather than an intermediate or unstable compound.

Understanding the Trade-offs

Temperature Precision vs. Grain Size

While the primary process relies on a 400°C setpoint, the furnace's ability to control temperature is vital for managing particle size.

Higher temperatures (e.g., above 550°C) can increase crystallinity but may also cause grain growth. If the temperature is too high, nanoparticles may sinter together, increasing their size (e.g., beyond the typical 16-28 nm range) and losing their useful "nano" properties.

Atmosphere Control

The standard process utilizes an air atmosphere to facilitate oxidation and impurity burnout.

However, the muffle design is critical here; it protects the sample from direct contact with heating elements or flames. This indirect heating prevents contamination from the furnace components themselves, but relies on the presence of oxygen to remove organics effectively.

Making the Right Choice for Your Goal

The operation of the muffle furnace must be tailored to the specific properties you require from the Nickel Oxide nanoparticles.

- If your primary focus is High Purity: Ensure the furnace maintains a steady 400°C for the full two hours with adequate airflow to fully oxidize and exhaust organic residues.

- If your primary focus is Particle Size Control: Monitor the thermal field strictly; even slight overheating can accelerate grain growth, pushing the particle size beyond the desired nanometer range.

Ultimately, the muffle furnace provides the precise thermal environment necessary to turn a raw chemical mixture into a functional, structured nanomaterial.

Summary Table:

| Process Function | Key Role in NiO Synthesis | Resulting Material Property |

|---|---|---|

| Thermal Decomposition | Breaks down green gel precursors | Formation of base metal oxide |

| Impurity Removal | Oxidizes and burns off organic volatiles | High chemical purity |

| Crystallography | Enables atomic migration at 400°C | Face-centered cubic (FCC) structure |

| Phase Control | Ensures complete chemical transformation | Single-phase NiO powder |

| Thermal Precision | Regulates energy to prevent sintering | Controlled grain size (16-28 nm) |

Optimize Your Nanomaterial Synthesis with KINTEK

Precision is the difference between high-purity nanoparticles and failed precursors. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the rigorous demands of thermal processing. Backed by expert R&D and manufacturing, our lab high-temp furnaces are fully customizable to your specific synthesis requirements, ensuring uniform heating and exact temperature control for consistent crystallization.

Ready to elevate your material research? Contact us today to find the perfect thermal solution for your laboratory.

Visual Guide

References

- Mamta Bulla, Ajay Kumar Mishra. Natural resource-derived NiO nanoparticles via aloe vera for high-performance symmetric supercapacitor. DOI: 10.1038/s41598-024-57606-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a high-precision multi-functional muffle furnace required in CGFS? Achieve Exact Decarbonization Metrics

- What are some common applications of a box type resistance furnace? Versatile High-Temp Solutions for Labs and Industry

- What is the critical role of a laboratory high-temperature muffle furnace in TiO2/LDH? Unlock Superior Crystallization

- How does the size of crucible furnaces impact their use? A Guide to Choosing the Right Scale

- What process conditions does a muffle furnace provide for rGO reduction? Master Graphene Oxide Thermal Processing

- What role does a muffle furnace play in the synthesis of Si@Al adsorbents? Master Precise Thermal Transformation

- What are the operating temperature ranges for different types of muffle furnaces? Find Your Ideal High-Temp Solution

- How are muffle furnaces used in the pharmaceutical industry? Essential for Quality Control and R&D