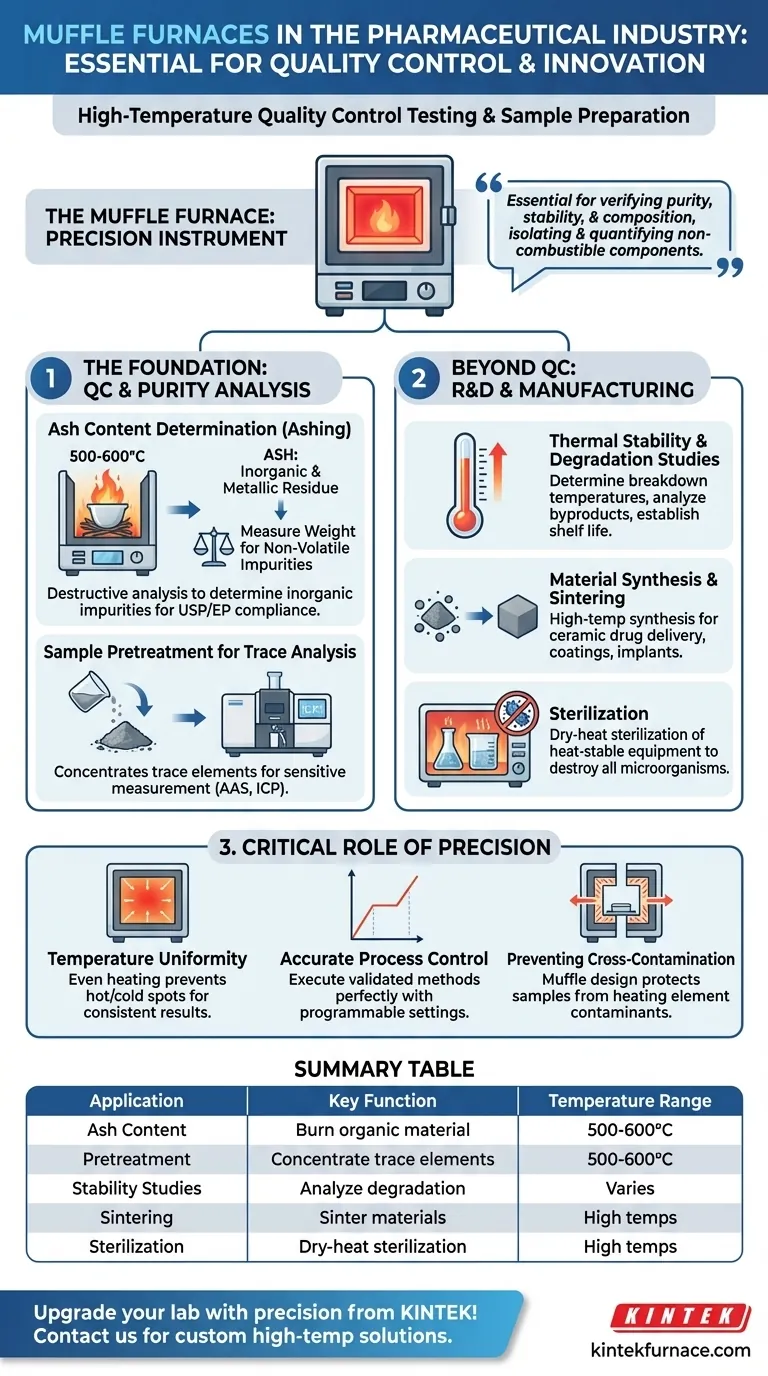

At its core, a muffle furnace is used in the pharmaceutical industry for high-temperature quality control testing and sample preparation. Its primary functions are to perform ashing analysis to determine the inorganic impurity content of a substance and to pretreat samples for further, more detailed analytical testing.

The muffle furnace is not merely a high-temperature oven; it is a precision instrument essential for verifying the purity, stability, and composition of pharmaceutical ingredients and finished products. Its role is to isolate and quantify the non-combustible components of a sample, ensuring it meets stringent safety and quality standards.

The Foundation: Quality Control and Purity Analysis

In a regulated industry like pharmaceuticals, verifying the exact composition of a substance is non-negotiable. The muffle furnace is a primary tool for achieving this through destructive analysis.

Ash Content Determination

Ashing is the most common pharmaceutical application of a muffle furnace. The process involves heating a sample at a very high temperature (typically 500-600°C) to completely burn away all organic material.

What remains is the ash, which consists of the sample's inorganic and metallic components.

Measuring the weight of this residual ash is a critical quality control test. It reveals the quantity of non-volatile inorganic impurities, which must remain below strict limits defined by pharmacopoeias like the USP or EP.

Sample Pretreatment for Trace Analysis

The ashing process also serves as a sample preparation step for more sensitive analytical methods.

By reducing a complex organic sample to simple inorganic ash, trace elements become concentrated and easier to measure. This ash can then be dissolved and analyzed using techniques like Atomic Absorption Spectroscopy (AAS) or Inductively Coupled Plasma (ICP) to identify and quantify specific metallic contaminants.

Beyond QC: Research, Development, and Manufacturing

While quality control is its primary role, the muffle furnace's capabilities extend into creating and testing the next generation of medicines and materials.

Thermal Stability and Degradation Studies

Researchers use muffle furnaces to conduct thermal degradation studies. By exposing a drug substance or excipient to extreme heat, they can identify its breakdown temperature and analyze the byproducts.

This data is crucial for determining a product's shelf life, establishing proper storage conditions, and ensuring its stability throughout the manufacturing process.

Material Synthesis and Sintering

In pharmaceutical R&D, muffle furnaces are used for the high-temperature synthesis of novel materials. This includes sintering, a process where powdered materials are heated to form a solid mass without melting.

Sintering is essential for creating certain ceramic-based drug delivery systems, biocompatible coatings, or medical implants where precise porosity and material density are required.

Sterilization of Heat-Stable Equipment

For certain applications, muffle furnaces can be used for the dry-heat sterilization of laboratory equipment, such as glassware or stainless steel instruments. The extremely high temperatures ensure the complete destruction of all microorganisms, including resilient bacterial spores.

Understanding the Critical Role of Precision

The value of a muffle furnace in pharmaceuticals comes not just from its heat, but from its control. Inconsistent results can lead to failed batches or incorrect safety data.

Why Temperature Uniformity is Non-Negotiable

A high-quality muffle furnace provides exceptional temperature uniformity throughout its chamber. This ensures the entire sample is heated evenly, preventing hot or cold spots that would lead to incomplete combustion or inconsistent analytical results.

The Need for Accurate Process Control

Pharmaceutical test methods specify precise temperature ramp rates, hold times, and setpoints. A programmable muffle furnace allows analysts to execute these validated methods perfectly every time, ensuring that results are repeatable and defensible during regulatory audits.

Preventing Cross-Contamination

The "muffle" design is itself a key feature. It is a chamber that isolates the sample from the heating elements. This prevents contaminants from the heating elements (which can degrade over time) from falling into the sample and skewing the results of a sensitive trace metal analysis.

Making the Right Choice for Your Goal

The specific application of a muffle furnace dictates the most important considerations.

- If your primary focus is routine Quality Control: Prioritize a furnace with proven temperature uniformity and repeatability to ensure your ash content results are consistent and meet pharmacopoeial requirements.

- If your primary focus is Research and Development: Seek a furnace with advanced programming capabilities for complex thermal cycling, which is essential for material synthesis and degradation studies.

- If your primary focus is Process Validation and Manufacturing: Focus on robust construction and capacity, as the furnace will be used for critical processes like sintering or sterilization that directly impact final product quality.

Ultimately, the muffle furnace serves as a fundamental gatekeeper for quality and a powerful tool for innovation within the pharmaceutical landscape.

Summary Table:

| Application | Key Function | Temperature Range |

|---|---|---|

| Ash Content Determination | Burn organic material to measure inorganic impurities | 500-600°C |

| Sample Pretreatment | Concentrate trace elements for analysis (e.g., AAS, ICP) | 500-600°C |

| Thermal Stability Studies | Analyze drug degradation and stability | Varies by study |

| Material Synthesis | Sinter materials for drug delivery systems | High temperatures as needed |

| Sterilization | Dry-heat sterilization of equipment | High temperatures for spore destruction |

Upgrade your pharmaceutical lab with precision high-temperature solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure they meet your unique experimental needs for quality control, research, and production. Contact us today to discuss how our reliable, uniform-heating muffle furnaces can enhance your purity analysis and innovation—let's ensure your products meet the highest standards!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis

- What role does a muffle furnace play in g-C3N4 synthesis? Mastering Thermal Polycondensation for Semiconductors

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration