A high-precision multi-functional muffle furnace is the indispensable tool for quantifying the efficiency of the Coal Gasification Fine Slag (CGFS) separation process. It is specifically required to perform ignition and calcination analysis on flotation products, subjecting samples to a constant $950^{\circ}\mathrm{C}$ environment to accurately determine yield and ash content.

Core Insight: The muffle furnace serves as the "source of truth" for CGFS processing. By removing all combustible materials through precise thermal treatment, it provides the essential quantitative data needed to evaluate how effectively the flotation process has decarbonized the slag.

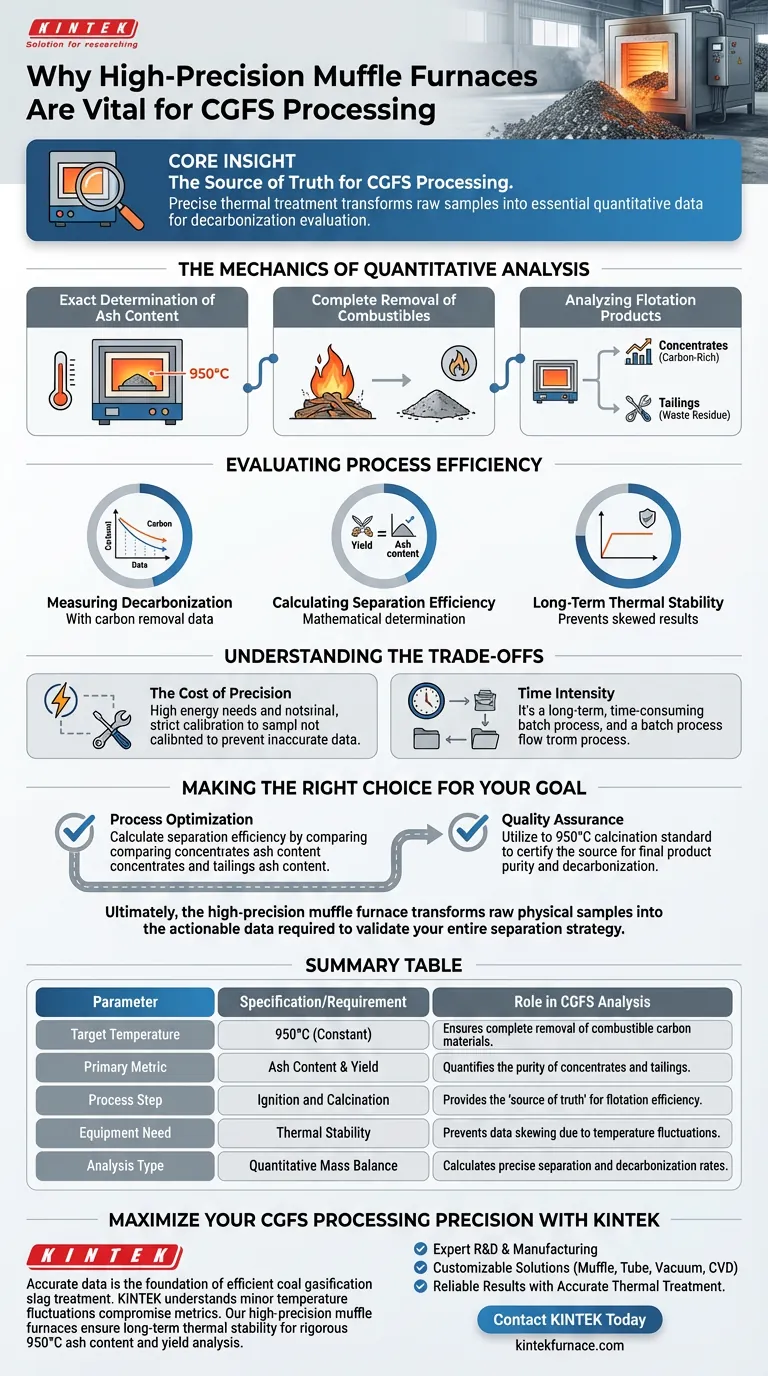

The Mechanics of Quantitative Analysis

Exact Determination of Ash Content

To understand the composition of CGFS, one must separate the combustible carbon from the incombustible residue. The muffle furnace achieves this by heating samples to $950^{\circ}\mathrm{C}$.

Complete Removal of Combustibles

At this specific temperature, all combustible materials within the slag are burned away. This leaves behind only the ash, allowing for a precise measurement of the material's purity.

Analyzing Flotation Products

The furnace is not just for raw slag; it handles the specific outputs of the separation process. It analyzes both concentrates (the carbon-rich output) and tailings (the waste residue) to provide a complete picture of mass balance.

Evaluating Process Efficiency

Measuring Decarbonization

The primary goal of processing CGFS is usually decarbonization. Data from the muffle furnace reveals exactly how much carbon was removed, validating the success of the treatment.

Calculating Separation Efficiency

You cannot improve a process you cannot measure. By comparing the yield and ash content of the concentrates against the tailings, operators can mathematically determine the separation efficiency of the flotation setup.

Long-Term Thermal Stability

The "high-precision" aspect of the furnace is critical for data integrity. It ensures that the temperature remains constant over long periods, preventing thermal fluctuations from skewing the analytical results.

Understanding the Trade-offs

The Cost of Precision

High-precision furnaces require significant energy and strict calibration to maintain a stable $950^{\circ}\mathrm{C}$. Any deviation in temperature control can lead to incomplete combustion or volatile loss, rendering the efficiency data inaccurate.

Time Intensity

This is not a rapid-test method. The reference notes the requirement for long-term constant temperature heating, meaning this analysis is a time-consuming batch process rather than a real-time monitoring solution.

Making the Right Choice for Your Goal

To utilize a muffle furnace effectively in CGFS processing, align your usage with your specific data requirements:

- If your primary focus is Process Optimization: Use the furnace to compare ash content between concentrates and tailings to calculate precise separation efficiency.

- If your primary focus is Quality Assurance: Rely on the $950^{\circ}\mathrm{C}$ calcination standard to certify the final purity and decarbonization level of your product.

Ultimately, the high-precision muffle furnace transforms raw physical samples into the actionable data required to validate your entire separation strategy.

Summary Table:

| Parameter | Specification/Requirement | Role in CGFS Analysis |

|---|---|---|

| Target Temperature | $950^{\circ}C$ (Constant) | Ensures complete removal of combustible carbon materials. |

| Primary Metric | Ash Content & Yield | Quantifies the purity of concentrates and tailings. |

| Process Step | Ignition and Calcination | Provides the 'source of truth' for flotation efficiency. |

| Equipment Need | Thermal Stability | Prevents data skewing due to temperature fluctuations. |

| Analysis Type | Quantitative Mass Balance | Calculates precise separation and decarbonization rates. |

Maximize Your CGFS Processing Precision with KINTEK

Accurate data is the foundation of efficient coal gasification slag treatment. At KINTEK, we understand that even minor temperature fluctuations can compromise your decarbonization metrics. Our high-precision muffle furnaces are engineered for long-term thermal stability, providing the rigorous $950^{\circ}C$ environment required for definitive ash content and yield analysis.

Why partner with KINTEK?

- Expert R&D & Manufacturing: Our systems are built for the demanding duty cycles of industrial mineral analysis.

- Customizable Solutions: From specialized Muffle and Tube furnaces to Vacuum and CVD systems, we tailor our high-temp lab solutions to your unique research needs.

- Reliable Results: Ensure your flotation process is validated by the most accurate thermal treatment technology available.

Ready to elevate your lab’s analytical integrity? Contact KINTEK today to discuss your customized furnace requirements and see how our expert-backed manufacturing can drive your process efficiency.

Visual Guide

References

- Yang Jiao, Wenhao Tang. Ultrasonication Improves the Flotation of Coal Gasification Fine Slag Residue. DOI: 10.3390/min14040363

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the advantages and disadvantages of bottom load furnaces? Unlock Superior Thermal Uniformity and Control

- What role does a box-type muffle furnace play in NBR waste pyrolysis screening? Master Thermal Baseline Data

- How is the box furnace's door secured and what safety feature does it have? Ensuring Safe Operation with Robust Design

- What are the temperature capabilities of a muffle furnace? Find Your Perfect High-Temp Solution

- What training is required for operators of a muffle furnace? Essential Skills for Safe and Efficient Operation

- Why is the use of a Muffle Furnace critical during the calcination stage of TiO2/g-C3N4? Master Composite Synthesis

- What role does a muffle furnace play in 600°C carbonization of palm shells? Unlock High-Performance Activated Carbon

- How is a muffle furnace utilized in the annealing of bismuth-lead-borosilicate glass? Mastering Stress Relief