A box furnace door is secured through a simple and robust mechanical system that combines a multi-level hinge with a lever-action handle. The door closes tightly using the handle's own weight, creating a secure seal. Critically, it includes a safety interlock switch that immediately cuts power to the heating elements the moment the door is opened, preventing operator exposure to thermal and electrical hazards.

The furnace's design philosophy is one of layered safety. It pairs a reliable physical door closure with an automatic electrical cutoff, ensuring that the primary hazard—energized heating elements—is neutralized before an operator can access the chamber.

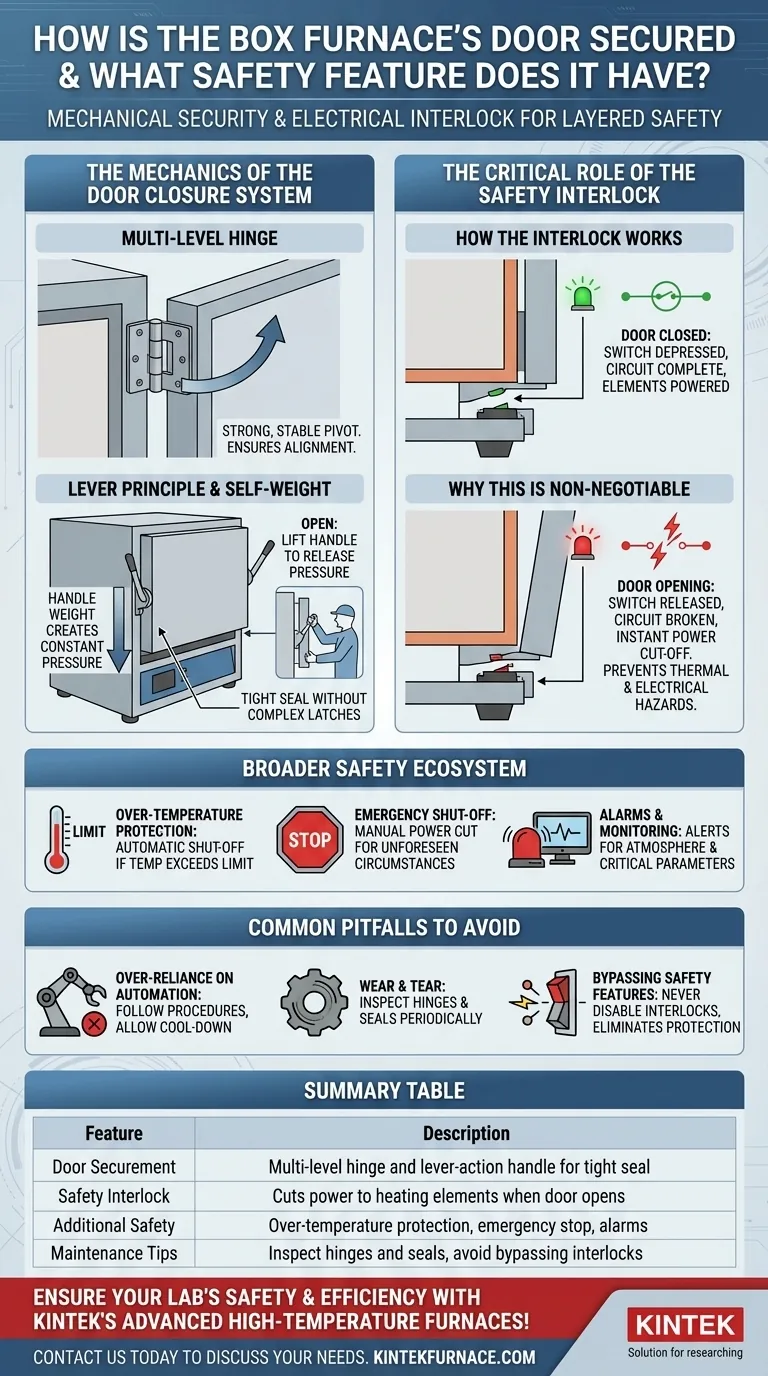

The Mechanics of the Door Closure System

Understanding the door's mechanical design reveals its inherent reliability. The system is designed for simplicity and consistent performance without complex, failure-prone latches.

The Multi-Level Hinge

The door is mounted to the furnace body using a multi-level hinge. This provides a strong, stable pivot point that ensures the door swings away smoothly and aligns correctly when being closed.

The Lever Principle and Self-Weight

Closure is not achieved by a traditional latch but by the clever use of physics. The handle is designed so that its own weight, acting through a lever, pulls the door firmly against the furnace face. This creates a constant, secure pressure for a tight seal.

Opening the Door

To open the door, an operator simply lifts the handle lock upward. This action overcomes the handle's self-weight, releasing the pressure. On some models, a secondary rubber hook may also need to be unlatched before the door can be swung open to the side.

The Critical Role of the Safety Interlock

While the mechanical closure contains heat, the electrical interlock is the most critical active safety feature of the door system.

How the Interlock Works

Located at the lower end of the furnace opening, the safety interlock is a small switch. When the door is closed, it physically depresses this switch, completing the electrical circuit and allowing the heating elements to receive power.

The instant the door begins to open, the switch is released. This immediately breaks the circuit, cutting off all power to the heating elements.

Why This is a Non-Negotiable Feature

This design acts as a fundamental failsafe. It makes it physically impossible for an operator to open the door and be exposed to electrically live heating coils. It protects against severe burns and electrical shock, forming the cornerstone of the furnace's operational safety.

Understanding the Broader Safety Ecosystem

The door interlock does not work in isolation. It is part of a larger system of controls and failsafes designed to protect the operator, the equipment, and the materials inside.

Over-Temperature Protection

This is a secondary temperature controller that monitors the furnace independently. If the primary controller fails and the temperature rises beyond a safe limit, this system will shut off the furnace, preventing a catastrophic meltdown.

Emergency Shut-Off Controls

Virtually all modern furnaces are equipped with a large, conspicuous emergency stop button. This allows an operator to manually cut all power to the unit in any unforeseen circumstance that the automated systems do not detect.

Alarms and Monitoring

Modern program-controlled furnaces often include systems that monitor critical parameters like internal atmosphere (e.g., oxygen content) in addition to temperature. If any parameter deviates from the setpoint, an audible or visual alarm will alert the operator to the problem.

Common Pitfalls to Avoid

Trusting the equipment requires understanding its limitations and the operator's role in maintaining safety.

Over-Reliance on Automation

While the interlock is effective, it should not replace proper procedure. Operators should always ensure a heating program is complete and allow for a cool-down period before opening the door to avoid thermal shock to the sample and unnecessary heat exposure.

Wear and Tear on Mechanical Parts

The hinge, handle, and door seal are all mechanical components subject to wear. They should be inspected periodically to ensure the door continues to align and seal properly. A compromised seal leads to heat loss and energy inefficiency.

Bypassing Safety Features

Under no circumstances should the door interlock or any other safety feature be disabled or bypassed. Doing so eliminates the core protection built into the furnace and creates an extremely hazardous operating condition.

Making the Right Choice for Your Goal

By understanding these integrated systems, you can ensure safe, reliable, and effective use of the box furnace.

- If your primary focus is operator safety: Always verify the function of the door interlock and know the location of the emergency shut-off before beginning any operation.

- If your primary focus is equipment longevity: Routinely inspect the door's hinge and seal for wear and ensure the over-temperature protection is set correctly to prevent accidental damage.

- If your primary focus is process integrity: Rely on the full suite of monitoring systems and alarms, not just the door, to confirm the internal environment remains stable throughout your process.

A deep understanding of these integrated mechanical and electrical safety systems empowers you to operate the equipment with both confidence and security.

Summary Table:

| Feature | Description |

|---|---|

| Door Securement | Multi-level hinge and lever-action handle for tight seal |

| Safety Interlock | Cuts power to heating elements when door opens |

| Additional Safety | Over-temperature protection, emergency stop, alarms |

| Maintenance Tips | Inspect hinges and seals, avoid bypassing interlocks |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable solutions like Box, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how our furnaces can enhance your operations and protect your team!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in synthesizing P2-Na0.67Ni0.33Mn0.67O2? Key to High-Performance Cathodes

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits