Bottom load furnaces provide exceptional thermal uniformity and process control, making them a superior choice for sensitive, high-value applications. Their design, where the load is lifted into a sealed, pre-heated chamber, ensures highly consistent heating. However, this performance comes with the trade-off of a more complex mechanical system that requires a higher initial investment and specific maintenance.

The decision to use a bottom load furnace hinges on a simple trade-off: accepting higher mechanical complexity and cost in exchange for unparalleled temperature uniformity and process environment control.

The Core Advantage: Superior Thermal Performance

The fundamental design of a bottom load furnace is its greatest strength. By raising the product into a stationary, sealed heating chamber, it overcomes many limitations of traditional front-loading designs.

How Bottom Loading Achieves Uniformity

A bottom load furnace's heating elements are typically arranged symmetrically around the chamber walls. When the hearth raises the workload into the center of this chamber, the product is exposed to even, radiant heat from all sides and below. This eliminates the hot and cold spots common in other furnace types.

Furthermore, because the chamber remains sealed until the hearth is lowered, there is minimal temperature fluctuation or atmospheric disturbance during loading and unloading cycles.

Impact on Process Quality

This high degree of temperature uniformity is not just a technical detail; it is critical for process success. In applications like sintering advanced ceramics, growing single crystals, or performing precise metallurgical treatments, temperature variations of even a few degrees can ruin an entire batch.

The consistent environment ensures that every part of the workload experiences the exact same thermal profile, leading to repeatable, high-quality results.

Energy Efficiency as a Byproduct

Excellent thermal uniformity and superior insulation directly translate to high thermal efficiency. The tight seal created by the rising hearth minimizes heat loss, especially compared to the large, often warped doors of front-loading furnaces. This means less energy is consumed to maintain the target temperature, reducing operational costs over the furnace's lifetime.

Key Benefits in Application

Beyond thermal performance, the bottom-loading design offers practical advantages for specific processes and handling requirements.

Unmatched Process Versatility

These furnaces are highly adaptable. They are used across numerous industries for demanding processes, including:

- Brazing and annealing metals

- Sintering and densifying technical ceramics

- Growing crystals for semiconductors and optics

- Firing dental prosthetics

The precise control over both temperature and atmosphere makes them a go-to solution for materials research and specialized production.

Precise Atmosphere Control

Many advanced processes require a controlled atmosphere (e.g., inert gas like Argon, or a vacuum). The design of a bottom load furnace, with its hearth sealing against the chamber's bottom flange, creates an exceptionally tight seal. This makes it easier to maintain a pure atmosphere and achieve deeper vacuum levels than in most other furnace configurations.

Simplified Handling of Heavy or Delicate Loads

While the lift cycle itself takes time, the external hearth makes the manual loading process much safer and easier for certain workloads. Heavy, tall, or delicate assemblies can be carefully arranged on the hearth platform with full 360-degree access before being lifted into the chamber. This is far less awkward and risky than trying to place a heavy object deep inside a hot furnace chamber with tongs.

Understanding the Trade-offs and Disadvantages

The advanced capabilities of a bottom load furnace are balanced by clear operational and financial considerations.

The Hearth Lift Mechanism

The primary disadvantage is the complexity of the hearth lift system. Whether it uses an electromechanical screw jack or a hydraulic system, this mechanism is a point of maintenance and potential failure. It requires regular inspection and service to ensure reliable and safe operation, which contributes to the "expensive to maintain" perception.

Higher Initial Investment

The structural frame, lift system, and precise sealing surfaces make bottom load furnaces inherently more expensive to manufacture than a simple front-loading box furnace of a similar volume. This higher upfront cost must be justified by the need for superior process results.

Cycle Time Considerations

While manual loading can be easier, the overall process cycle can be longer. The time required for the mechanical lift to operate, both up and down, adds to the total cycle time. For high-throughput applications with simple parts, this can be a significant bottleneck compared to quickly opening and closing a door.

Facility and Footprint Requirements

A bottom load furnace requires significant vertical clearance. You must have enough space below the furnace for the hearth to lower completely for loading and unloading. This can be a major constraint in labs or production floors with low ceilings.

Making the Right Choice for Your Process

Your decision should be guided by the non-negotiable requirements of your thermal process.

- If your primary focus is ultimate temperature uniformity and process purity: A bottom load furnace is the technically superior choice, especially for sensitive materials, crystal growth, or advanced ceramics.

- If your primary focus is handling large, heavy, or awkwardly shaped parts: The external hearth of a bottom loader can offer a safer and more ergonomic loading solution.

- If your primary focus is high-volume throughput of simple parts: A front-loading batch furnace may be more time-efficient and cost-effective.

- If your primary focus is minimizing initial cost and maintenance complexity: A standard front-loading box furnace is a simpler and more economical option for general-purpose heat treating.

Ultimately, choosing a bottom load furnace is an investment in process precision, where the operational benefits justify the mechanical complexity.

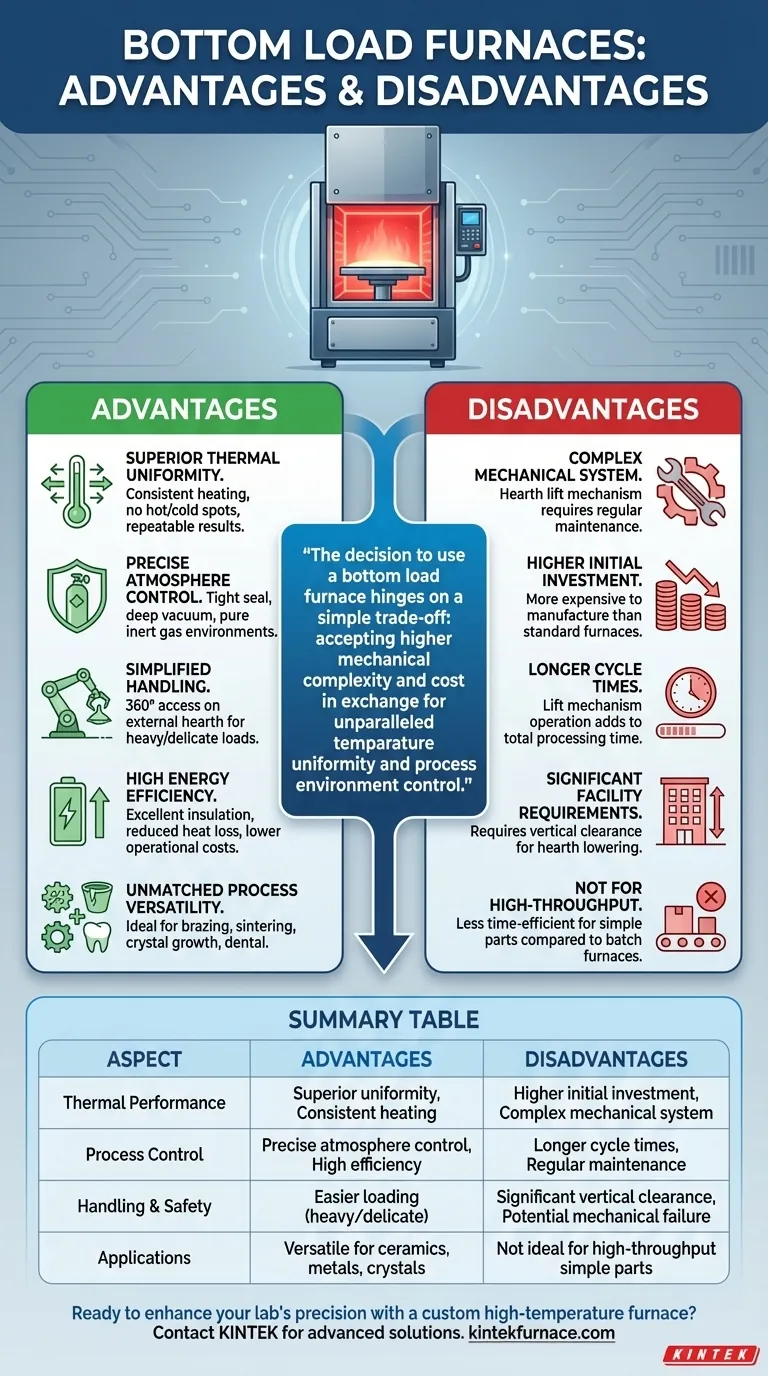

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Thermal Performance | Superior temperature uniformity, consistent heating, minimal fluctuations | Higher initial investment, complex mechanical system |

| Process Control | Precise atmosphere control, high thermal efficiency, repeatable results | Longer cycle times, requires regular maintenance |

| Handling & Safety | Easier loading for heavy/delicate loads, 360-degree access | Requires significant vertical clearance, potential for mechanical failure |

| Applications | Versatile for ceramics, metals, crystals, dental prosthetics | Not ideal for high-throughput simple parts due to cycle times |

Ready to enhance your lab's precision with a custom high-temperature furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior thermal uniformity and process control. Contact us today to discuss how we can optimize your thermal processes and deliver reliable, high-quality results tailored to your needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals