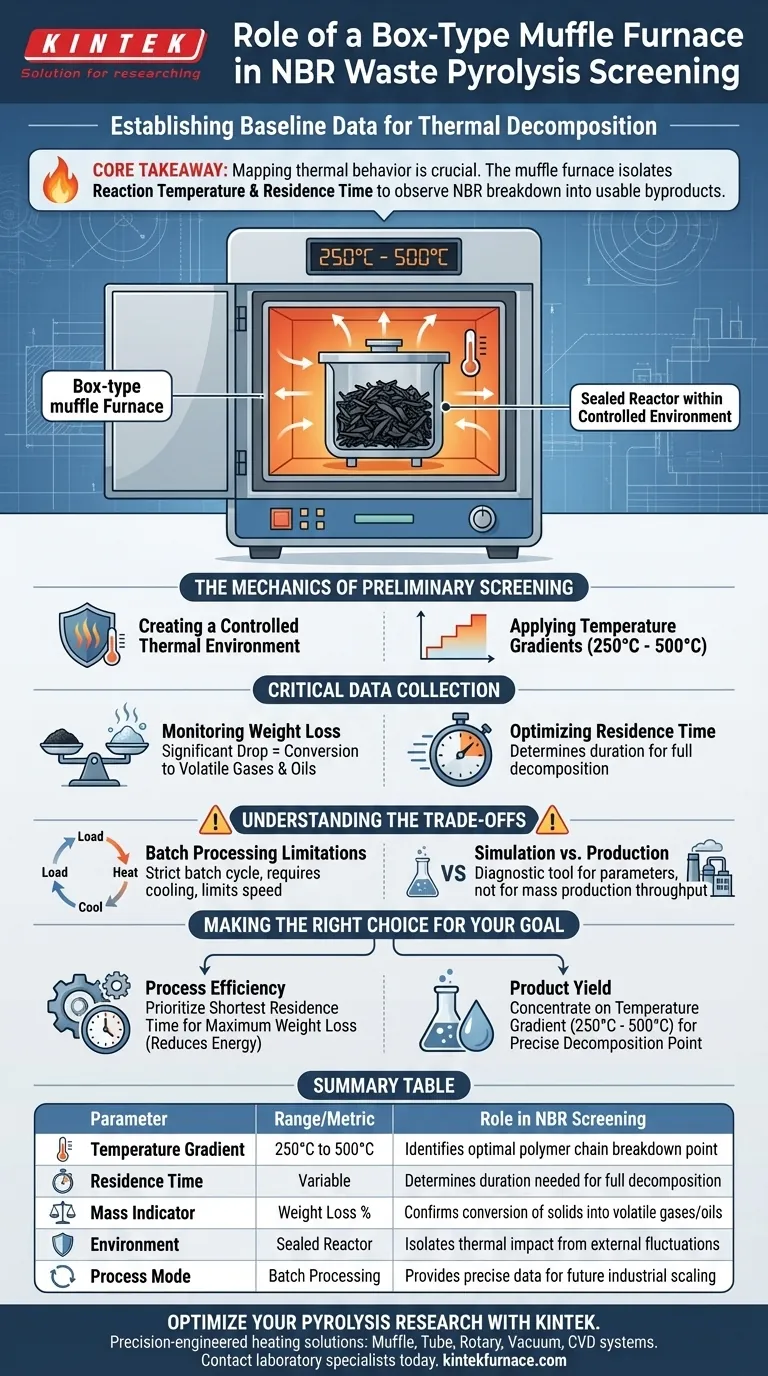

A box-type muffle furnace serves as the foundational testing ground for determining how Nitrile Butadiene Rubber (NBR) waste responds to thermal decomposition. By housing a sealed reactor within a precisely controlled environment, the furnace allows researchers to subject samples to specific temperature gradients ranging from 250°C to 500°C. This preliminary screening is the only reliable way to establish the baseline data needed to design larger-scale pyrolysis systems.

Core Takeaway Before large-scale recycling can occur, the thermal behavior of NBR must be mapped. The muffle furnace facilitates this by isolating the two most critical variables—reaction temperature and residence time—allowing researchers to observe exactly when and how the rubber breaks down into usable byproducts.

The Mechanics of Preliminary Screening

Creating a Controlled Thermal Environment

The primary function of the muffle furnace is to provide a stable, high-temperature atmosphere.

Unlike open combustion, this process involves placing the NBR waste into a sealed reactor which is then inserted into the furnace.

This setup ensures that the variable being tested is strictly the impact of heat on the material, isolating it from external fluctuations.

Applying Temperature Gradients

To find the "sweet spot" for decomposition, the furnace is not simply set to a single maximum temperature.

Researchers utilize the furnace to test a specific range, primarily between 250°C and 500°C.

By stepping through these temperatures, the equipment helps identify the exact point where the polymer chains in the rubber begin to break down effectively.

Critical Data Collection

Monitoring Weight Loss

The most immediate indicator of successful pyrolysis screening is the reduction in sample mass.

As the furnace maintains the set temperature, researchers observe the weight loss of the NBR sample.

A significant drop in weight indicates that the solid rubber is successfully converting into volatile gases and oils, confirming the efficiency of the thermal parameters.

Optimizing Residence Time

Temperature is only half of the equation; duration is the other.

The furnace allows researchers to measure how long the material must remain at a specific temperature to achieve full decomposition.

This data defines the residence time, a critical metric for ensuring efficiency in future industrial operations.

Understanding the Trade-offs

Batch Processing Limitations

The box-type muffle furnace operates on a strict batch cycle, not a continuous flow.

As noted in standard operation procedures, the user must load the sample, heat the chamber, and wait for the controller to stabilize the temperature.

Crucially, the furnace must be allowed to cool down before the sample can be safely removed, which limits the speed of rapid-fire testing.

Simulation vs. Production

It is important to recognize that this equipment is for screening and trials, not mass production.

The data gathered here determines the parameters, but the muffle furnace itself cannot handle the throughput required for industrial waste management.

It is a diagnostic tool designed to prevent costly errors when scaling up to larger reactors.

Making the Right Choice for Your Goal

To maximize the utility of a box-type muffle furnace for NBR screening, focus your experiments based on your specific data needs:

- If your primary focus is Process Efficiency: Prioritize testing for the shortest residence time that still achieves maximum weight loss to reduce energy consumption in the long run.

- If your primary focus is Product Yield: Concentrate on the temperature gradient (250°C - 500°C) to identify the precise temperature that yields the most complete decomposition without degrading the resulting oils.

Success in NBR pyrolysis relies on using this screening phase to eliminate guesswork before scaling up.

Summary Table:

| Parameter | Range/Metric | Role in NBR Screening |

|---|---|---|

| Temperature Gradient | 250°C to 500°C | Identifies optimal polymer chain breakdown point |

| Residence Time | Variable | Determines duration needed for full decomposition |

| Mass Indicator | Weight Loss % | Confirms conversion of solids into volatile gases/oils |

| Environment | Sealed Reactor | Isolates thermal impact from external fluctuations |

| Process Mode | Batch Processing | Provides precise data for future industrial scaling |

Optimize Your Pyrolysis Research with KINTEK

Don’t leave your NBR recycling yields to guesswork. At KINTEK, we empower labs with precision-engineered heating solutions designed to bridge the gap between screening and production. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique thermal decomposition needs.

Ready to achieve superior thermal mapping? Contact our laboratory specialists today to find the perfect furnace for your research and take the first step toward scalable industrial efficiency.

Visual Guide

References

- Kasun Pathiraja, Kaveenga Rasika Koswattage. Sustainable Management of Nitrile Butadiene Rubber Waste Through Pyrolysis. DOI: 10.3390/su17030846

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a high-precision muffle furnace required for BCZT xerogel pre-calcination? Ensure Pure Phase and Reactivity

- How are muffle furnaces and vacuum sealing techniques applied to evaluate high-entropy alloys? Expert Stability Guide

- How should temperature be managed when using a muffle furnace? Master Precise Control for Safety and Accuracy

- What fire safety equipment should be available when using a benchtop furnace? Essential Gear for Lab Safety

- Why is working temperature the most crucial factor when choosing a muffle furnace? Ensure Your Process Success with the Right Heat

- What is the function of a high-temperature muffle furnace in g-C3N4 synthesis? Optimize Your Photocatalyst Production

- What are the disadvantages of using a muffle furnace? Key Limitations and Better Alternatives

- What are the advantages of using a laboratory infrared heating furnace for PET waste conversion? Boost Energy Efficiency