Indeed, the working temperature is the single most critical factor when selecting a muffle furnace. If a furnace cannot reach and sustain the specific temperature your process requires, all other features—size, control systems, and safety interlocks—become irrelevant. It is the fundamental pass/fail test for any potential furnace.

While many factors contribute to a good purchasing decision, the required working temperature is the one non-negotiable parameter. It dictates the furnace's core technology, construction, and cost, making it the first and most important filter in your selection process.

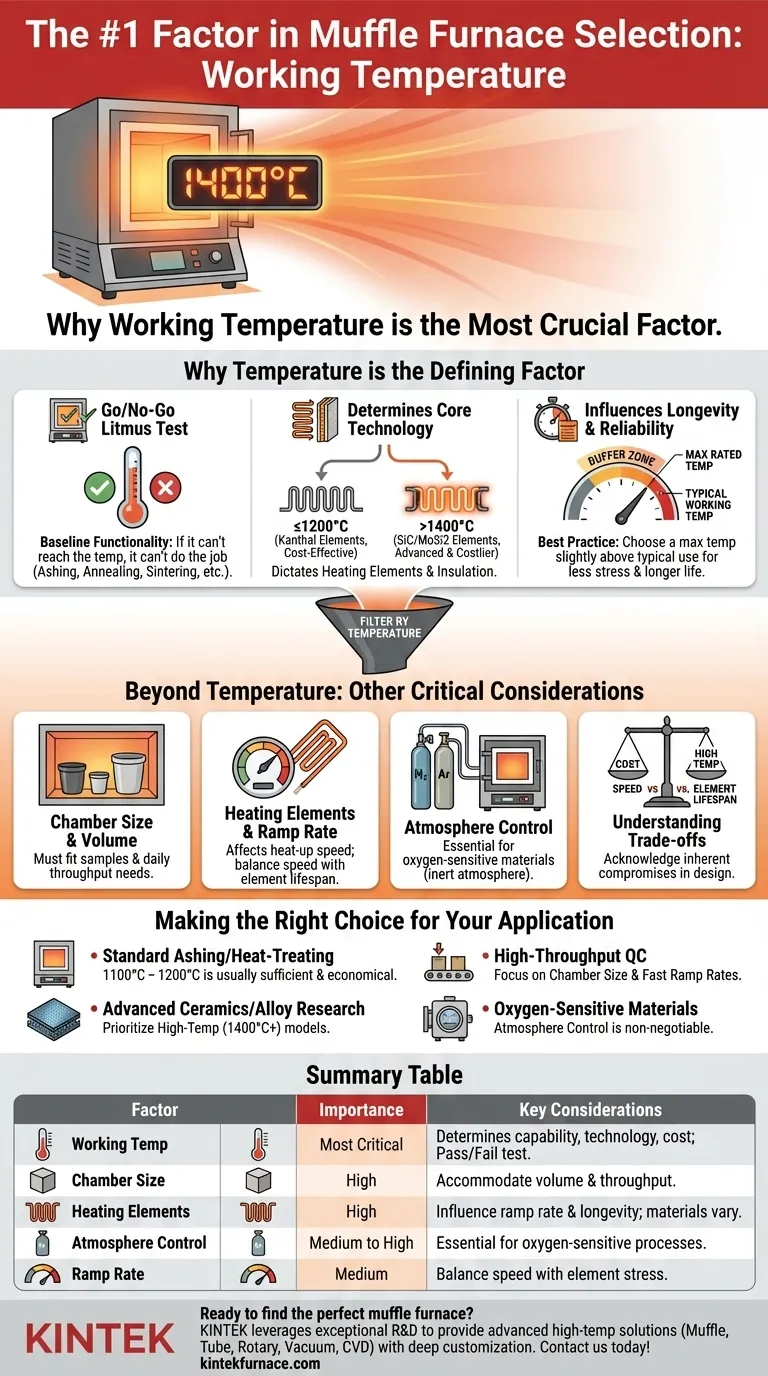

Why Temperature Is the Defining Factor

Understanding why temperature holds this primary position helps frame the entire decision. It's not just about hitting a number; it's about the physics and engineering that number demands.

The "Go/No-Go" Litmus Test

The purpose of a furnace is to achieve a specific thermal process, such as ashing, annealing, sintering, or heat-treating. Each of these applications has a well-defined temperature requirement.

If your application requires 1300°C and the furnace is only rated for 1100°C, it simply cannot perform the work. This makes temperature the absolute baseline for functionality.

It Determines Core Furnace Technology

The maximum operating temperature directly dictates the furnace's most critical and expensive components: the heating elements and the insulation.

Standard furnaces operating up to 1100-1200°C often use durable, cost-effective Kanthal (FeCrAl alloy) elements. However, achieving higher temperatures (e.g., 1400°C or more) requires more advanced and costly materials like Silicon Carbide (SiC) or Molybdenum Disilicide (MoSi2).

This means a higher temperature requirement fundamentally changes the engineering of the furnace, leading to a significant increase in its purchase price.

It Influences Longevity and Reliability

Constantly operating a furnace at its absolute maximum rated temperature places immense stress on its heating elements and insulation, shortening its operational lifespan.

A best practice is to choose a furnace with a maximum temperature slightly above your typical working temperature. This provides a performance buffer, ensuring the furnace is not over-strained during routine use, which leads to greater reliability and a longer service life.

Beyond Temperature: Other Critical Considerations

Once you have filtered your options by working temperature, other factors come into play to ensure the furnace is a perfect fit for your workflow.

Chamber Size and Sample Volume

The internal chamber dimensions must be large enough to accommodate your samples, crucibles, or parts. Consider not just the size of a single sample, but the throughput you need to achieve in a given day.

Heating Elements and Ramp Rate

The "ramp rate" is the speed at which the furnace heats up to the target temperature. For some time-sensitive processes or quality control labs, a fast ramp rate is crucial for efficiency. This is directly tied to the power and type of heating elements.

Atmosphere Control

Standard muffle furnaces operate with air. However, many advanced material processes require an inert atmosphere (like nitrogen or argon) to prevent oxidation. If this is your need, you must select a furnace specifically designed with gas-inlet ports and a sealed chamber.

Understanding the Trade-offs

An effective decision requires acknowledging the inherent compromises in furnace design.

High Temperature vs. Cost

This is the most significant trade-off. Each step up in temperature capability, particularly above 1200°C, results in a non-linear price increase due to the exotic materials required for elements and insulation. Be certain you need the higher temperature before paying for it.

Speed vs. Element Lifespan

While fast ramp rates are desirable for throughput, they can put additional thermal stress on heating elements. A more moderate, controlled ramp rate is often gentler on the components, contributing to a longer life.

Chamber Size vs. Uniformity

Achieving perfect temperature uniformity—where every point inside the chamber is at the exact same temperature—is more challenging in a larger chamber. For applications requiring extremely high precision, a smaller, well-designed chamber may provide better results.

Making the Right Choice for Your Application

Filter your options based on your primary goal.

- If your primary focus is standard ashing or general heat-treating: A cost-effective furnace with a maximum temperature of 1100°C to 1200°C is almost always the correct and most economical choice.

- If your primary focus is advanced ceramics or specialty alloy research: You must prioritize a high-temperature model (1400°C+) and budget accordingly for the required technology.

- If your primary focus is high-throughput quality control: Chamber size and a fast, programmable ramp rate become nearly as important as the maximum temperature.

- If your primary focus is processing oxygen-sensitive materials: The availability of atmosphere control is a non-negotiable feature that must be considered alongside your temperature needs.

Choosing the right furnace begins and ends with a clear understanding of your process requirements, starting with the one factor that dictates all others: temperature.

Summary Table:

| Factor | Importance | Key Considerations |

|---|---|---|

| Working Temperature | Most Critical | Determines furnace capability, element type, and cost; acts as a pass/fail test for applications. |

| Chamber Size | High | Must accommodate sample volume and throughput needs for efficiency. |

| Heating Elements | High | Influence ramp rate and longevity; materials vary with temperature (e.g., Kanthal for ≤1200°C, SiC/MoSi2 for higher). |

| Atmosphere Control | Medium to High | Essential for oxygen-sensitive processes; requires sealed chambers and gas ports. |

| Ramp Rate | Medium | Affects process speed and element stress; balance with lifespan for reliability. |

Ready to find the perfect muffle furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in materials research, quality control, or industrial processing, we ensure precise temperature control, durability, and efficiency. Don't let temperature limitations hold you back—contact us today to discuss how we can enhance your thermal processes and deliver reliable performance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control