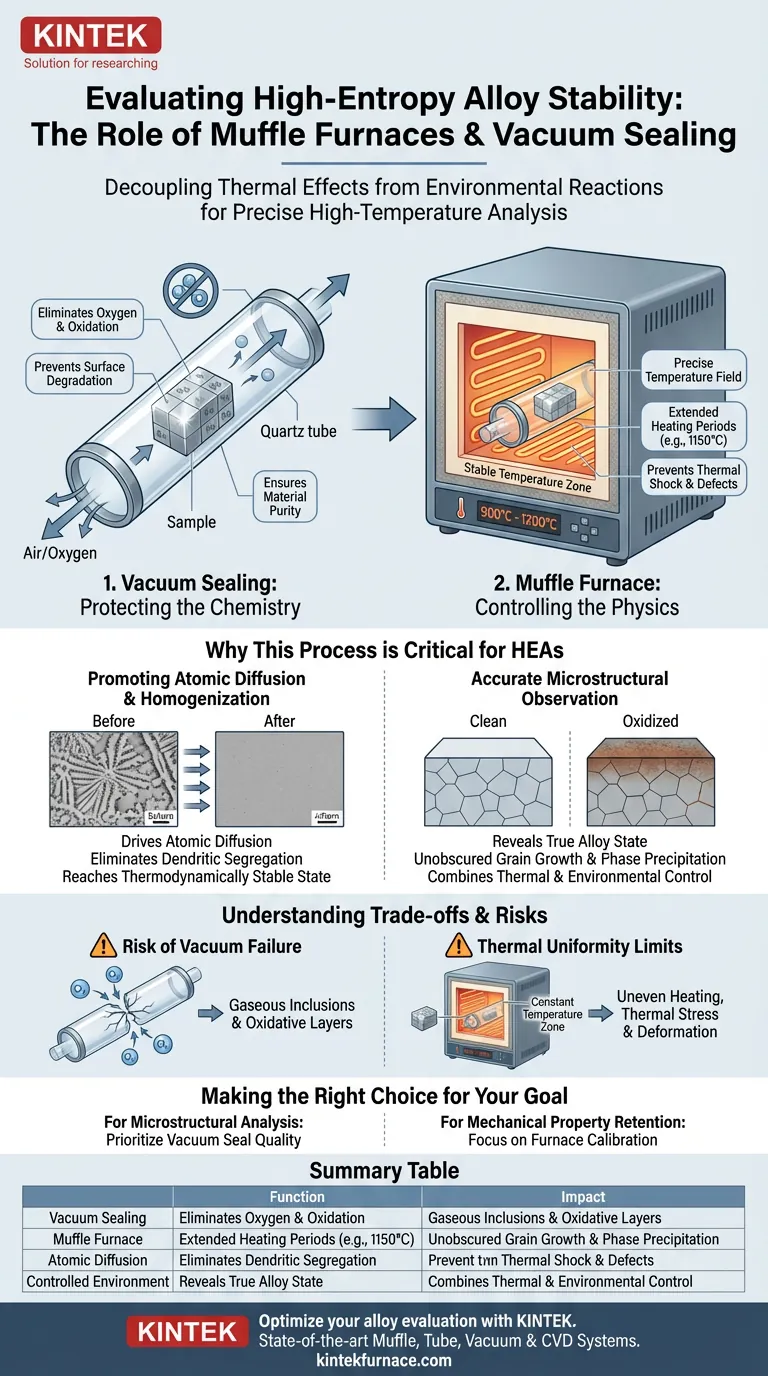

Muffle furnaces combined with vacuum sealing provide the essential controlled environment required to evaluate the high-temperature stability of high-entropy alloys (HEAs). This technique allows researchers to subject alloy samples to extreme heat—typically ranging from 900°C to 1200°C—while physically isolating them from oxygen to prevent catastrophic surface degradation.

The core purpose of this setup is to decouple thermal effects from environmental reactions. By maintaining a stable temperature field within a vacuum, you ensure that any observed changes in the alloy are due to intrinsic microstructural evolution, not external oxidation.

The Two-Part Mechanism for Stability Evaluation

The Role of Vacuum Sealing

The primary threat to HEAs at elevated temperatures is oxidation. Without protection, samples heated to 900°C or above will rapidly form thick oxide layers.

Vacuum sealing techniques—often involving encapsulating samples in evacuated quartz tubes—eliminate this variable. By extracting air and creating a negative pressure environment, you remove the oxygen necessary for oxides to form. This ensures the material remains pure throughout the annealing process.

The Role of the Muffle Furnace

While the seal protects the chemistry, the muffle furnace controls the physics. These furnaces are designed to deliver a highly stable temperature field.

The furnace maintains the sample at a precise target temperature (e.g., holding at 1150°C) for extended periods. This thermal uniformity is critical; fluctuations can cause thermal shock, leading to defects such as pores, cracks, or warping that would ruin the evaluation.

Why This Process is Critical for HEAs

Promoting Atomic Diffusion

High-entropy alloys often suffer from dendritic segregation (uneven element distribution) following their initial casting.

The sustained heat provided by the muffle furnace drives atomic diffusion. This process homogenizes the alloy, eliminating segregation and allowing the material to reach a thermodynamically stable state. This "reset" is necessary before you can accurately test how stable the alloy truly is.

Accurate Microstructural Observation

To evaluate stability, you must observe how the microstructure evolves (e.g., grain growth or phase precipitation) over time.

If the sample surface oxidizes, it obscures these internal changes. By combining the muffle furnace with vacuum sealing, you ensure that the post-heat treatment analysis reflects the true state of the alloy, rather than a compromised surface layer.

Understanding the Trade-offs

The Risk of Vacuum Failure

The reliability of your data depends entirely on the integrity of the seal. Even a microscopic leak in a quartz tube or vacuum bag at 1200°C will introduce oxygen.

This leads to "gaseous inclusions" or oxidative layers that can be mistaken for internal phase changes. Rigorous checking of the vacuum quality prior to heating is non-negotiable.

Thermal Uniformity Limits

While muffle furnaces are designed for stability, they have "constant temperature zones" of limited size.

Placing a sample outside this optimal zone results in uneven heating. This can induce thermal stress and deformation, which directly interferes with the measurement of mechanical properties like plasticity and strength.

Making the Right Choice for Your Goal

To obtain valid data on high-entropy alloy stability, tailor your approach to your specific objective:

- If your primary focus is Microstructural Analysis: Prioritize the quality of the vacuum seal (e.g., high-quality quartz encapsulation) to prevent surface oxides from obscuring grain boundaries and phase precipitates.

- If your primary focus is Mechanical Property Retention: Focus on the calibration of the muffle furnace's "constant temperature zone" to prevent thermal gradients that cause physical defects like cracking or warping.

By strictly controlling the atmosphere and the thermal field simultaneously, you transform a destructive heating process into a precise analytical tool.

Summary Table:

| Evaluation Component | Primary Function | Impact on HEA Stability Testing |

|---|---|---|

| Vacuum Sealing | Prevents Oxidation | Eliminates surface degradation; ensures purity for microstructural observation. |

| Muffle Furnace | Thermal Uniformity | Provides stable, high-temperature fields (900°C-1200°C) to drive atomic diffusion. |

| Atomic Diffusion | Homogenization | Eliminates dendritic segregation and reaches a thermodynamically stable state. |

| Controlled Environment | Decoupling Effects | Separates intrinsic microstructural changes from external environmental reactions. |

Precision is paramount when testing advanced materials like high-entropy alloys. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for high-temperature research. Whether you need precise thermal uniformity or customizable atmosphere control, our lab furnaces provide the stability your research demands. Optimize your alloy evaluation with KINTEK today and leverage our expertise in custom lab high-temp solutions.

Visual Guide

References

- Xiaoyu Ding, Jianhua Yao. Study on Microstructure and High Temperature Stability of WTaVTiZrx Refractory High Entropy Alloy Prepared by Laser Cladding. DOI: 10.3390/e26010073

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What critical environmental conditions does a muffle furnace provide for aluminum cast iron? Optimize Your Heat Treatment

- What role does a high-temperature box-type resistance furnace play in the synthesis of NiMoO4 microflowers?

- Why might a muffle furnace consume high energy? Tips to Cut Costs and Boost Efficiency

- What is a box type resistance furnace and what is it used for? Discover Precision Heating Solutions

- What is the significance of a high-temperature chamber sintering furnace in alumina lattice performance? Master Densification

- What are common high-temperature applications of muffle furnaces in laboratories? Unlock Precision in Material Testing and Synthesis

- What is the purpose of using a high-temperature oven for the pretreatment of anhydrous calcium chloride?

- What is important about chamber size in muffle furnaces? Ensure Accurate Heating with the Right Zone