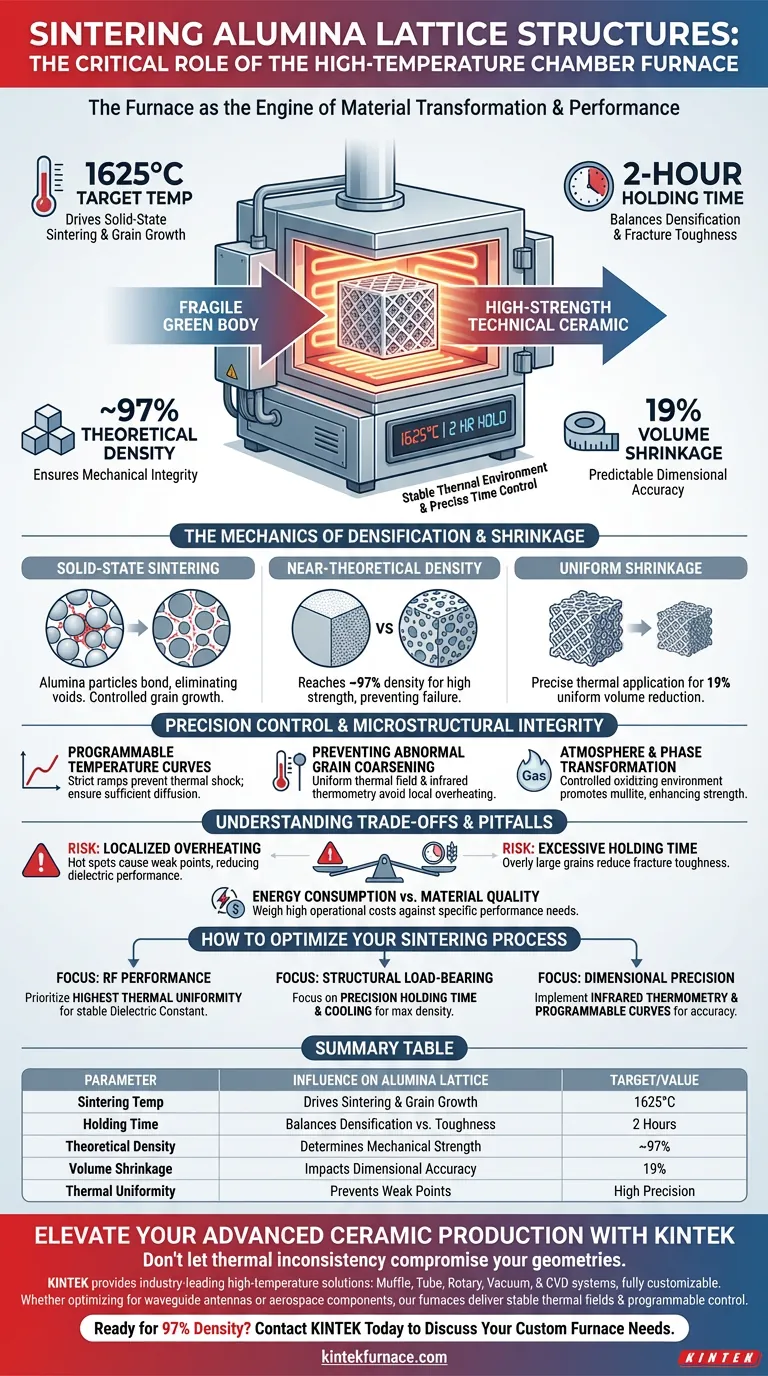

The sintering furnace is the critical engine of material transformation. A high-temperature chamber sintering furnace determines the final performance of alumina lattice structures by providing a stable 1625°C environment and a precise two-hour holding time. This controlled thermal process drives solid-state sintering and grain growth, directly resulting in a theoretical density of approximately 97% and a predictable 19% volume shrinkage.

The sintering furnace acts as the definitive quality control mechanism, converting a fragile green body into a high-strength technical ceramic. By maintaining thermal uniformity, it ensures the alumina lattice achieves the specific mechanical integrity and dielectric constant required for advanced applications like waveguide antennas.

The Mechanics of Densification and Shrinkage

Facilitating Solid-State Sintering

At the target temperature of 1625°C, the furnace initiates solid-state sintering, where alumina particles bond at the atomic level. This high-energy environment allows for controlled grain growth, which is essential for eliminating internal voids.

Achieving Near-Theoretical Density

The furnace’s ability to maintain a consistent thermal field ensures the structure reaches roughly 97% of its theoretical density. High density is the primary driver of mechanical strength, preventing structural failure under operational stress.

Managing Uniform Volume Shrinkage

Precise thermal application results in a uniform 19% volume shrinkage across the lattice. This predictability is vital for maintaining the dimensional accuracy of complex geometries used in RF engineering and aerospace components.

Precision Control and Microstructural Integrity

The Role of Programmable Temperature Curves

Advanced furnaces utilize programmable temperature control to execute strict heating and cooling ramps. This prevents thermal shock and ensures that different elements within the ceramic matrix diffuse sufficiently at preset temperatures.

Preventing Abnormal Grain Coarsening

High-precision measurement tools, such as infrared thermometry, prevent local overheating that leads to abnormal grain coarsening. Maintaining a uniform microstructure is the only way to guarantee performance consistency across the entire lattice.

Atmosphere and Phase Transformation

Industrial-grade furnaces often provide a controlled oxidizing atmosphere that facilitates necessary chemical reactions. This environment supports the development of specific crystalline phases, such as mullite, which fill pores and further enhance the material's flexural strength.

Understanding the Trade-offs and Pitfalls

The Risk of Localized Overheating

If the thermal field is not perfectly uniform, "hot spots" can cause localized grain growth, which creates weak points in the lattice. These microstructural defects significantly reduce the dielectric performance and mechanical reliability of the final part.

Balancing Holding Time and Grain Size

While a two-hour holding time is standard for densification, excessive time at peak temperature can lead to overly large grains. Larger grains often result in reduced fracture toughness, illustrating the delicate balance between density and structural resilience.

Energy Consumption vs. Material Quality

Achieving 1625°C requires significant energy and specialized heating elements, such as molybdenum disilicide. Engineers must weigh the high operational costs against the performance requirements of the specific application.

How to Optimize Your Sintering Process

To ensure your alumina lattice structures meet the necessary performance benchmarks, consider the following strategic focuses:

- If your primary focus is RF performance: Prioritize furnaces with the highest thermal uniformity to ensure a stable and predictable dielectric constant across the lattice.

- If your primary focus is structural load-bearing: Focus on the precision of the holding time and cooling ramp to maximize density while preventing brittle grain coarsening.

- If your primary focus is dimensional precision: Implement infrared thermometry and programmable curves to manage the 19% shrinkage rate with sub-millimeter accuracy.

The high-temperature chamber furnace is not merely a heating tool, but the foundational instrument that defines the physical limits and functional success of alumina ceramics.

Summary Table:

| Parameter | Influence on Alumina Lattice | Target/Value |

|---|---|---|

| Sintering Temperature | Drives solid-state sintering & grain growth | 1625°C |

| Holding Time | Balances densification vs. fracture toughness | 2 Hours |

| Theoretical Density | Determines mechanical strength & integrity | ~97% |

| Volume Shrinkage | Impacts dimensional accuracy for RF/Aerospace | 19% |

| Thermal Uniformity | Prevents localized overheating & weak points | High Precision |

Elevate Your Advanced Ceramic Production with KINTEK

Don't let thermal inconsistency compromise your complex alumina geometries. KINTEK provides the industry-leading high-temperature solutions required for precision material transformation. Backed by expert R&D and advanced manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific sintering profiles.

Whether you are optimizing dielectric constants for waveguide antennas or maximizing mechanical strength for aerospace components, our furnaces deliver the stable thermal fields and programmable control you need to succeed.

Ready to achieve 97% theoretical density with absolute reliability? Contact KINTEK today to discuss your custom furnace needs.

Visual Guide

References

- Alice Rosa, Alberto Ortona. Design, Additive Manufacturing, and Electromagnetic Characterization of Alumina Cellular Structures for Waveguide Antenna. DOI: 10.1002/adem.202302159

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What process function does a high-temperature muffle furnace perform in pre-sintering spinel ceramics?

- How does the calcination process in a muffle furnace facilitate the formation of pores in manganese oxide?

- What is the function of a high-precision resistance furnace in the Al-Mg-Si alloy melting process? Achieve 750°C Stability

- What are the main benefits of using muffle furnaces? Achieve Purity and Precision in Heat Treatment

- What are the specific uses of muffle furnaces in laboratories? Essential for Contaminant-Free High-Temp Processes

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- What role does a laboratory high-temperature box furnace play in zirconia sintering? The Essential Scientific Baseline

- Why is input voltage important for muffle furnaces? Ensure Safety and Peak Performance