A high-temperature muffle furnace acts as a critical conditioning chamber during the pre-sintering phase of magnesium aluminum spinel ceramics. Its primary function is to provide a stable, air-atmosphere thermal environment that drives the controlled decomposition and partial volatilization of sintering additives, specifically Lithium Fluoride (LiF), while purging surface impurities from the powder particles.

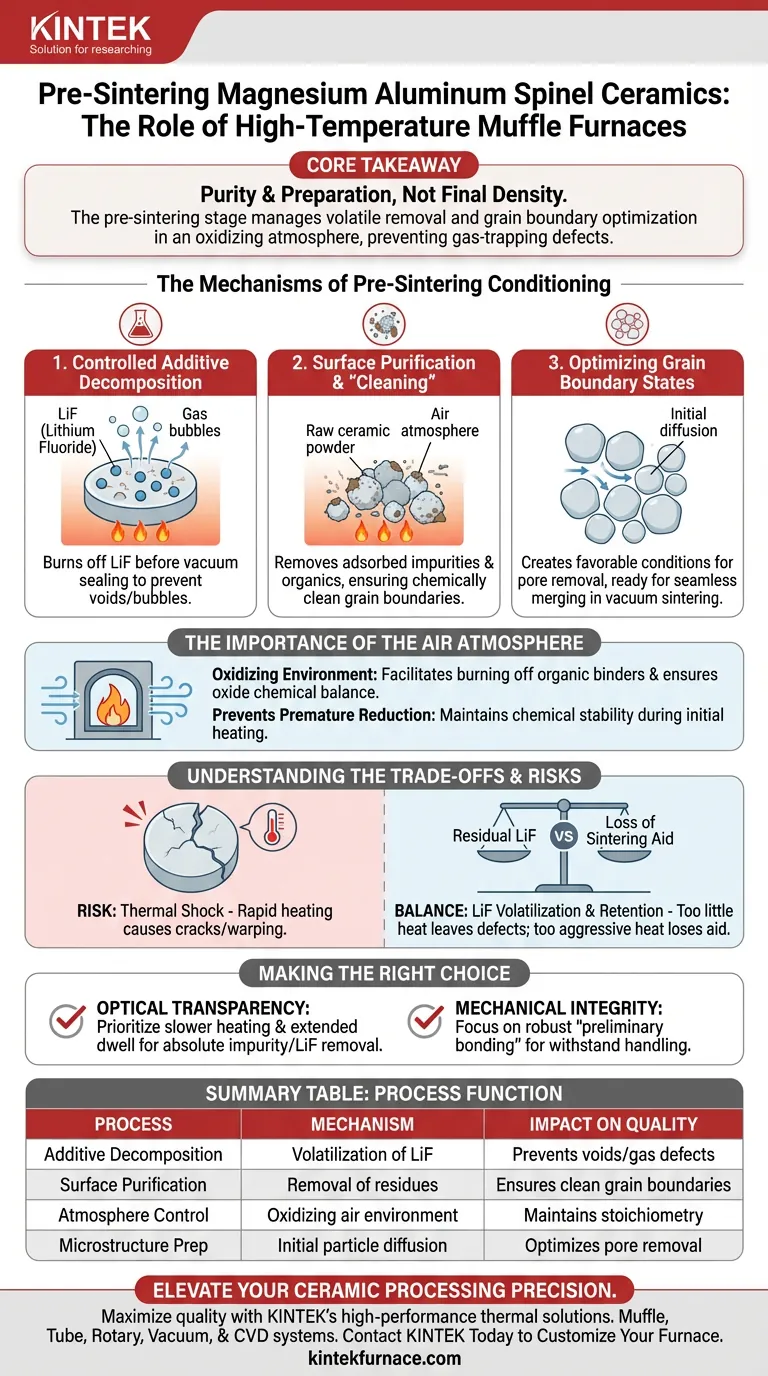

Core Takeaway The pre-sintering stage is not about achieving final density, but about purity and preparation. By managing the removal of volatiles and optimizing grain boundary states in an oxidizing atmosphere, the muffle furnace prevents the formation of gas-trapping defects that would otherwise ruin the material during the subsequent vacuum sintering process.

The Mechanisms of Pre-Sintering Conditioning

The muffle furnace performs three distinct operations that prepare the "green" (unfired) ceramic body for final processing.

Controlled Additive Decomposition

The addition of Lithium Fluoride (LiF) is common in spinel ceramics to lower sintering temperatures. However, residual LiF can be detrimental if not managed.

The muffle furnace heats the compact to a precise range where LiF begins to decompose and volatilize. This "burn-off" must happen before the material is sealed in a vacuum furnace; otherwise, the trapped volatiles would create voids or bubbles, destroying the optical and mechanical quality of the final ceramic.

Surface Purification and "Cleaning"

Raw ceramic powders often contain adsorbed impurities or organic residues from the pressing stage.

The high-temperature environment effectively cleans the surface of the powder particles. By removing these contaminants in an open air atmosphere, the furnace ensures that the grain boundaries—the interfaces between particles—are chemically clean. This is a prerequisite for high-quality diffusion later in the process.

Optimizing Grain Boundary States

Clean grain boundaries are essential for uniform densification.

By removing impurities and controlling the initial stage of diffusion, the furnace creates favorable conditions for pore removal. It establishes a microstructural state where the grains are ready to merge seamlessly once the material is transferred to the final vacuum sintering stage.

The Importance of the Air Atmosphere

While final sintering often occurs in a vacuum to eliminate pores, pre-sintering requires air.

Facilitating Oxidation

The air atmosphere within the muffle furnace provides an oxidizing environment. This is crucial for burning off organic binders and ensuring that oxide components maintain their correct stoichiometry (chemical balance).

Preventing Premature Reduction

For oxide ceramics, maintaining an oxygen-rich environment during the initial heating prevents unwanted reduction reactions. This ensures the material remains chemically stable as it approaches the temperatures required for phase transitions.

Understanding the Trade-offs

While pre-sintering is vital, incorrect parameters in the muffle furnace can lead to process failure.

The Risk of Thermal Shock

Heating the green body too rapidly can cause differential expansion, leading to cracks or warping before the ceramic has developed sufficient strength. The heating rate must be slow enough to allow volatiles to escape without rupturing the structure.

Balancing Volatilization and Retention

There is a delicate balance regarding the LiF additive. If the temperature is too low or the time too short, residual LiF may remain, causing defects later. Conversely, if the process is too aggressive, you may lose too much sintering aid, making it difficult to achieve full density in the final step.

Making the Right Choice for Your Goal

The specific settings of your muffle furnace should be tuned to the priority of your final application.

- If your primary focus is Optical Transparency: Prioritize a slower heating rate and extended dwell time to ensure absolute removal of impurities and LiF volatiles, as even microscopic trapped gas will cause haze.

- If your primary focus is Mechanical Integrity: Focus on the "preliminary bonding" aspect to ensure the green body creates a robust network that can withstand handling and transfer to the vacuum furnace without introducing micro-cracks.

Success in spinel ceramics is determined not just by the final sintering, but by the cleanliness and stability achieved during this pre-sintering conditioning.

Summary Table:

| Process Function | Mechanism | Impact on Quality |

|---|---|---|

| Additive Decomposition | Volatilization of LiF additives | Prevents voids and gas-trapping defects |

| Surface Purification | Removal of organic residues and impurities | Ensures clean grain boundaries for diffusion |

| Atmosphere Control | Oxidizing air environment | Maintains chemical stoichiometry and stability |

| Microstructure Prep | Initial particle diffusion | Optimizes pore removal for final densification |

Elevate Your Ceramic Processing Precision

Maximize the quality of your magnesium aluminum spinel ceramics with KINTEK’s high-performance thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of pre-sintering and surface purification.

Don't let trapped volatiles or impurities compromise your material's optical transparency and mechanical strength. Partner with KINTEK to achieve superior heat treatment results for your laboratory or industrial applications.

Contact KINTEK Today to Customize Your Furnace

Visual Guide

References

- Valorisation of Red Gypsum Waste in Polypropylene Composites for Agricultural Applications. DOI: 10.3390/polym17131821

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What PPE should be worn during maintenance and repairs of a benchtop furnace? Essential Gear for Your Safety

- What role does a muffle furnace play in the analytical chemical industry? Ensure Accurate, Contamination-Free Sample Processing

- What is the significance of box type resistance furnaces in lithium battery material synthesis? Unlock Precision and Efficiency

- How does the airflow and temperature distribution differ between drying ovens and muffle furnaces? Key Insights for Lab Efficiency

- What is the purpose of the muffle chamber in the furnace? Ensure Purity and Control in High-Temp Processes

- How are box type resistance furnaces utilized in composite material development? Essential for Precise Heat Treatment

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- How is a high-temperature muffle furnace utilized to evaluate the oxidation resistance of Cr2AlC ceramics?