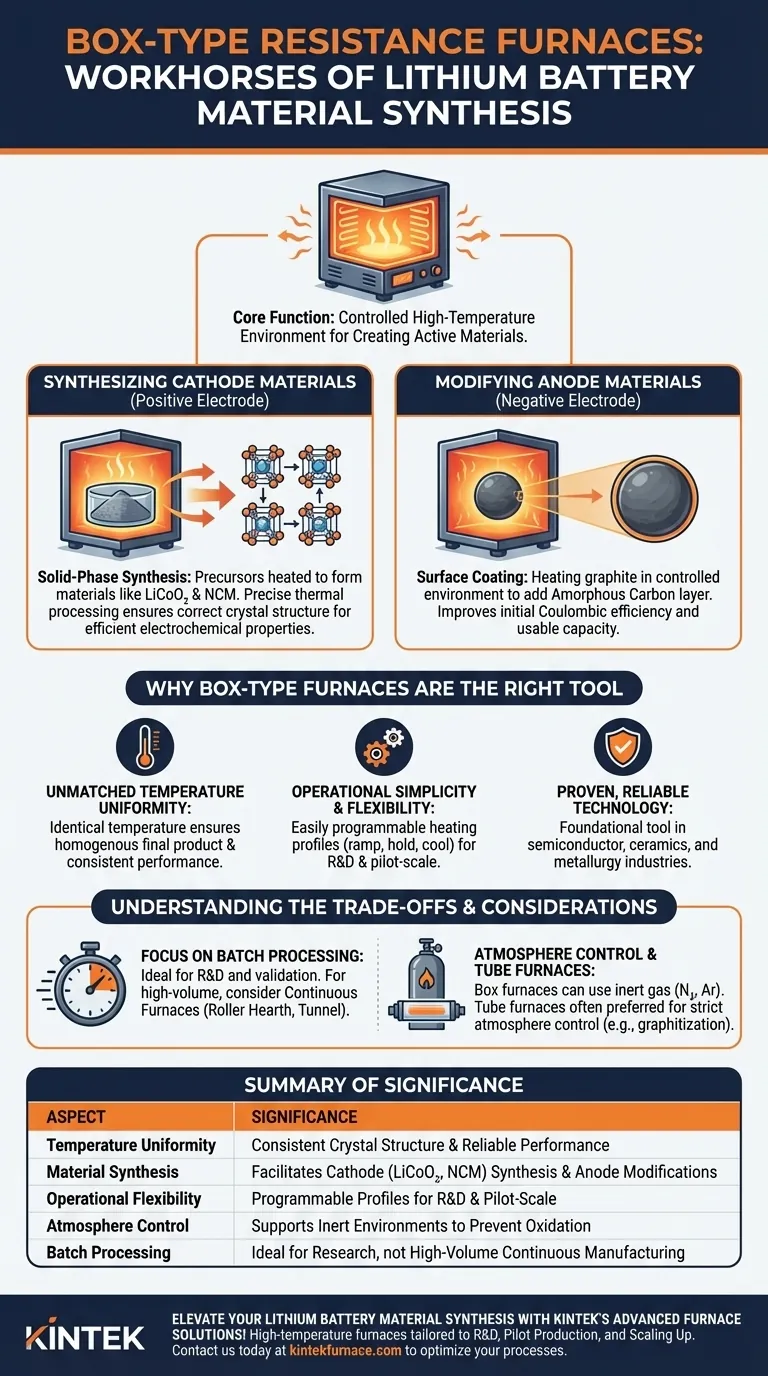

At their core, box-type resistance furnaces are the workhorses for creating the active materials in modern lithium-ion batteries. They provide the controlled, high-temperature environment essential for the solid-phase synthesis of positive electrode (cathode) materials like LiCoO₂ and NCM, and for the performance-enhancing modification of negative electrode (anode) materials.

The true significance of these furnaces lies not just in their ability to reach high temperatures, but in their capacity to do so with exceptional uniformity and control. This precision is what enables the specific chemical and structural transformations required to produce high-performance, reliable battery materials.

The Core Function: Creating High-Performance Battery Materials

A box-type furnace's primary role in this context is to act as a highly controlled oven, triggering specific chemical reactions that are only possible at elevated temperatures.

Synthesizing Positive Electrode (Cathode) Materials

The performance of a lithium-ion battery is largely defined by its cathode chemistry. Materials like Lithium Cobalt Oxide (LiCoO₂) and Nickel Cobalt Manganese (NCM) are created through a process called solid-phase synthesis.

Precursor materials are mixed and then heated in the furnace. The sustained, uniform heat causes the atoms to arrange themselves into the specific crystal structure needed for efficient lithium-ion insertion and extraction. Without this precise thermal processing, the material would lack the electrochemical properties required for a functioning battery.

Modifying Negative Electrode (Anode) Materials

While graphite is the standard anode material, its raw performance can be improved. Box-type furnaces are used for a critical modification step.

By heating graphite in a controlled environment, a thin layer of amorphous carbon can be coated onto its surface. This coating improves the material's initial Coulombic efficiency, meaning less lithium is wasted during the battery's first charge-discharge cycle, leading to a higher usable capacity.

Why Box-Type Furnaces are the Right Tool

These furnaces are not just one option among many; their fundamental characteristics make them uniquely suited for the demanding needs of battery material development and pilot-scale production.

Unmatched Temperature Uniformity

The most critical feature is temperature uniformity. The furnace is designed to ensure the temperature is virtually identical in every corner of the chamber.

This is non-negotiable for battery materials. Any temperature variation would result in a non-homogenous final product, with some parts having the correct crystal structure and others not. This leads to inconsistent performance and batch-to-batch unreliability.

Operational Simplicity and Flexibility

Box furnaces are known for their straightforward structure and user-friendly controls. This allows researchers and engineers to easily program heating profiles—controlling the ramp-up rate, hold time, and cool-down—to test and optimize synthesis protocols. Their design also accommodates various sample sizes, making them ideal for both laboratory-scale R&D and pilot production runs.

A Proven, Reliable Technology

The use of box-type furnaces is not limited to batteries. They are a foundational tool in industries with equally stringent requirements, such as semiconductor manufacturing, ceramics sintering, and metallurgical heat treatment. This widespread adoption is a testament to their reliability and the maturity of the technology.

Understanding the Trade-offs

While indispensable, it's important to understand the context and limitations of box-type furnaces to see the complete picture.

Focus on Batch Processing

By their very nature, box furnaces are designed for batch processing. Materials are loaded, heated, and then unloaded. This is perfect for research and process validation but becomes a bottleneck for high-volume, continuous manufacturing.

Industrial-scale production often transitions to systems like roller hearth kilns or tunnel furnaces, which can process material in a continuous flow, dramatically increasing throughput.

Tube Furnaces for Specific Applications

For certain processes, a tube furnace may be preferred. Tube furnaces offer excellent atmosphere control and are often used for processes like graphitization or carbonization where maintaining a specific gaseous environment (e.g., inert gas) is critical to prevent unwanted oxidation.

The Importance of Atmosphere Control

While a basic box furnace heats in air, many advanced material synthesis reactions require an inert or controlled atmosphere to prevent side reactions. Therefore, many box furnaces used in battery research are equipped with gas inlets and sealed doors to enable processing under gases like nitrogen or argon.

Making the Right Choice for Your Goal

The decision to use a box furnace depends entirely on your objective within the battery development lifecycle.

- If your primary focus is R&D and material discovery: A flexible, programmable box furnace is the ideal tool for experimenting with different chemical compositions and heating profiles.

- If your primary focus is pilot-scale production: A larger box furnace with certified temperature uniformity is critical for producing consistent, high-quality material to validate your synthesis process before scaling up.

- If your primary focus is high-volume manufacturing: The box furnace serves as the benchmark, but you will likely need to translate your process to a continuous furnace system to meet production demands.

Understanding the role of this foundational tool is the first step toward innovating and improving the materials that will power our future.

Summary Table:

| Aspect | Significance in Battery Material Synthesis |

|---|---|

| Temperature Uniformity | Ensures consistent crystal structure for reliable performance in cathodes and anodes. |

| Material Synthesis | Facilitates solid-phase synthesis of cathode materials (e.g., LiCoO₂, NCM) and anode modifications. |

| Operational Flexibility | Allows programmable heating profiles for R&D and pilot-scale production. |

| Atmosphere Control | Supports inert gas environments to prevent oxidation in advanced processes. |

| Batch Processing | Ideal for research and validation, though not for high-volume continuous manufacturing. |

Elevate your lithium battery material synthesis with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in R&D, pilot production, or scaling up, KINTEK delivers the precision and reliability you need. Contact us today to discuss how we can optimize your processes and boost efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity