In composite material development, a box-type resistance furnace is primarily utilized for two critical thermal processes. It is essential for the pre-oxidation of carbon fibers to stabilize their structure, and for the high-temperature sintering of ceramic matrix composites like SiC/SiC to achieve densification and superior performance.

Creating advanced composite materials is a game of controlling transformations at the atomic level. The core value of a box-type resistance furnace lies in its ability to provide the precise, uniform, and controllable thermal environment required to guide these material transformations successfully.

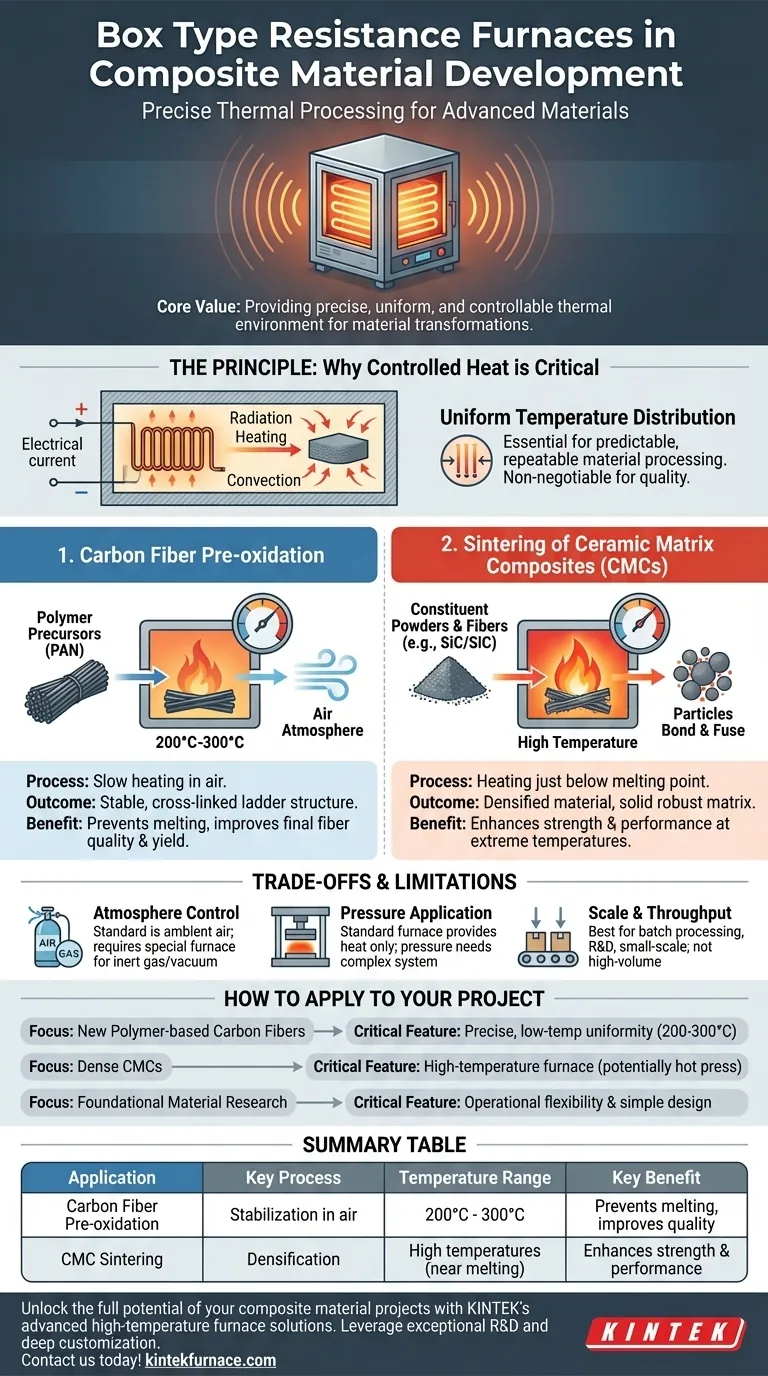

The Principle: Why Controlled Heat is Critical

A box-type resistance furnace is a foundational tool in materials science, but understanding its core mechanism reveals why it's so effective for composites.

How Resistance Heating Works

These furnaces generate heat by passing an electrical current through high-resistance heating elements, often made of specialized wire. This heat is then transferred to the material inside the chamber primarily through thermal radiation and convection.

The design is simple but powerful. It allows for a highly uniform temperature distribution within a well-insulated chamber, which is the most critical factor for predictable and repeatable material processing.

Why Uniformity is Non-Negotiable

In composite development, even small temperature variations can lead to structural defects, inconsistent properties, and ultimately, component failure. The reliable uniformity of a box furnace ensures that every part of the material undergoes the same thermal cycle, resulting in a homogenous and high-quality final product.

Core Applications in Composite Development

While versatile, the furnace's role in composites centers on two key, high-impact processes that define the material's final properties.

1. Carbon Fiber Pre-oxidation

Before carbon fibers can be carbonized at extreme temperatures, their polymer precursors (typically polyacrylonitrile, or PAN) must be stabilized.

The box furnace provides the ideal environment for this pre-oxidation step, which involves slowly heating the fibers in air at a precisely controlled temperature, usually between 200°C and 300°C. This process creates a stable, cross-linked ladder structure that won't melt or deform during subsequent high-temperature carbonization, dramatically improving the final fiber's quality and yield.

2. Sintering of Ceramic Matrix Composites (CMCs)

Ceramic Matrix Composites, such as Silicon Carbide-Silicon Carbide (SiC/SiC), are prized for their exceptional performance at extreme temperatures. Their creation relies on a process called sintering.

During sintering, the furnace heats the composite's constituent powders and fibers to a high temperature, just below their melting point. This causes the particles to bond and fuse, densifying the material and forming a solid, robust matrix around the reinforcing fibers. For some advanced CMCs, this process is combined with pressure in a specialized hot press furnace, which uses the same resistance heating principles.

Understanding the Trade-offs and Limitations

While powerful, a standard box-type resistance furnace is not a universal solution. Understanding its limitations is key to using it effectively.

Atmosphere Control

A basic box furnace operates in ambient air. This is perfect for oxidation processes but unsuitable for materials that would be damaged by oxygen at high temperatures. For those applications, a furnace with inert gas (e.g., Argon) or vacuum capabilities is required.

Pressure Application

The furnace itself only provides heat. Processes that require simultaneous heat and pressure, like hot pressing sintering, demand a more complex and integrated system. A standard box furnace cannot apply the mechanical pressure needed to aid densification in certain composites.

Scale and Throughput

Most box furnaces found in R&D labs are designed for batch processing, not continuous manufacturing. While larger industrial versions exist, the fundamental design is better suited for sample preparation, process development, and small-scale production rather than high-volume output.

How to Apply This to Your Project

Your choice of thermal processing equipment should be directly informed by the specific material and desired outcome.

- If your primary focus is developing new polymer-based carbon fibers: The furnace's precise, low-temperature (200-300°C) uniformity is your most critical feature for successful pre-oxidation.

- If your primary focus is creating dense Ceramic Matrix Composites (CMCs): You will need a high-temperature furnace, potentially a specialized hot press model, to achieve the necessary sintering and densification temperatures.

- If your primary focus is foundational material property research: The standard box furnace's operational flexibility and simple design make it an ideal, cost-effective tool for a wide range of exploratory heat treatment experiments.

Ultimately, the box-type resistance furnace is an indispensable instrument for manipulating material properties through the precise application of heat.

Summary Table:

| Application | Key Process | Temperature Range | Key Benefit |

|---|---|---|---|

| Carbon Fiber Pre-oxidation | Stabilization in air | 200°C - 300°C | Prevents melting, improves fiber quality |

| Ceramic Matrix Composite Sintering | Densification | High temperatures (e.g., near melting point) | Enhances strength and performance |

Unlock the full potential of your composite material projects with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precise, uniform heating systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for carbon fiber pre-oxidation, ceramic sintering, and more. Contact us today to discuss how our tailored solutions can enhance your material development efficiency and outcomes!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control