At its core, a muffle chamber is a specialized, insulated enclosure within a furnace that separates the material being heated from the direct heat source and its byproducts. Its fundamental purpose is to provide highly uniform, indirect heat while maintaining a controlled atmosphere. This design prevents contamination from combustion gases or direct contact with heating elements, ensuring the chemical purity of the sample.

The true value of a muffle chamber is not just its ability to get hot, but its ability to create a clean, stable, and predictable environment. By isolating the sample, it ensures that the only variable affecting it is pure, radiant heat, which is critical for repeatable and accurate results.

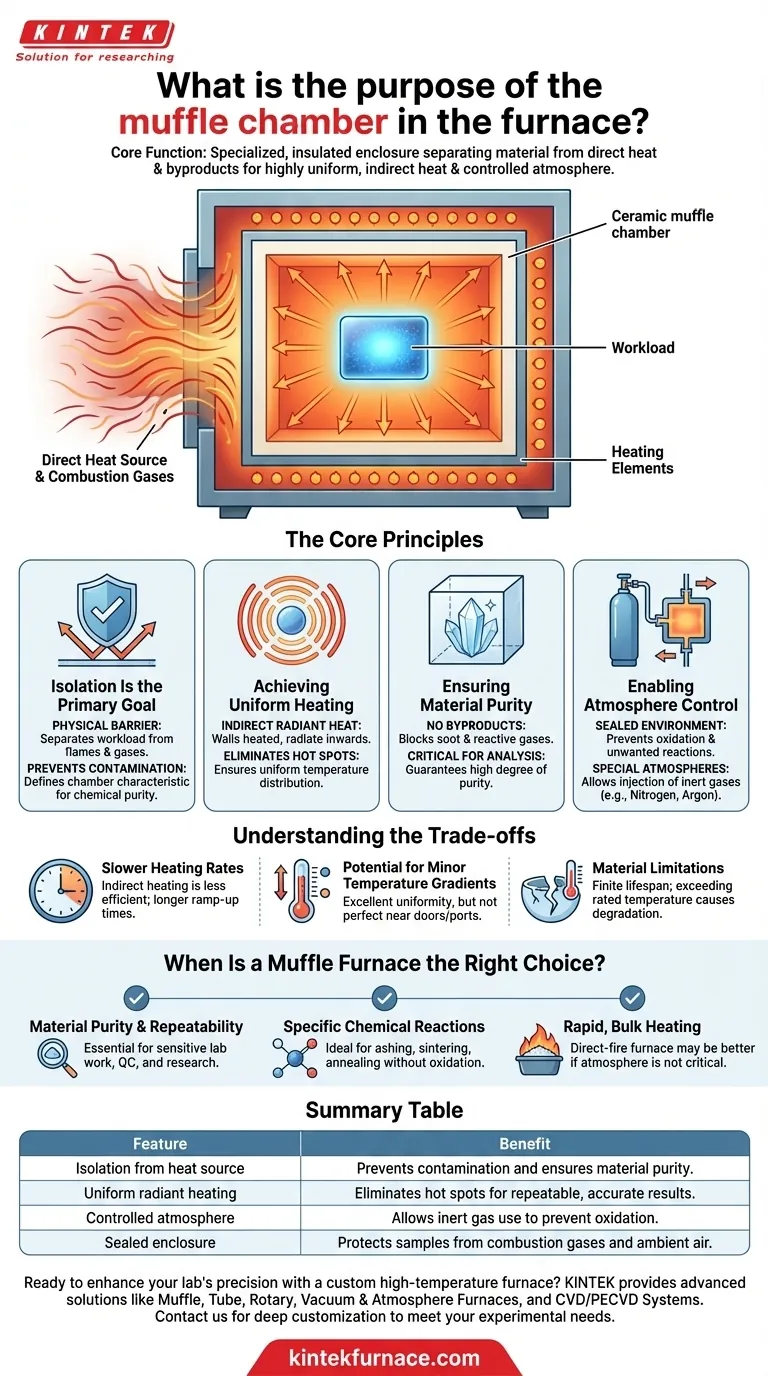

The Core Principles of a Muffle Chamber

The design of a muffle chamber is based on a few key engineering principles that make it indispensable for precise thermal processing. Understanding these principles clarifies why it is more than just a simple oven box.

Isolation Is the Primary Goal

The "muffle" acts as a barrier, or shield. It physically separates the workload from direct exposure to flames, combustion gases, and electric heating elements.

This separation is the chamber's defining characteristic. Without it, a furnace would expose the sample to turbulent, chemically reactive environments that could alter its composition.

Achieving Uniform Heating

Instead of heating the sample directly, the furnace's elements heat the walls of the muffle chamber. These heated walls then radiate thermal energy inward from all directions.

This method of indirect, radiant heat transfer ensures a much more uniform temperature distribution across the surface of the sample. It eliminates the "hot spots" that can occur with direct heating.

Ensuring Material Purity

By preventing combustion byproducts like soot or reactive gases from touching the sample, the muffle chamber guarantees a high degree of purity.

This is critical in scientific analysis and advanced materials processing, where even trace amounts of contamination can invalidate results or ruin the final product.

How the Chamber Enables Atmosphere Control

The isolation provided by the muffle is the foundation for controlling the chemical environment during heating. This is essential for many advanced applications.

Preventing Oxidation and Unwanted Reactions

For many processes, such as the ashing of a sample or the sintering of powdered metals, exposure to oxygen at high temperatures is undesirable.

The sealed nature of the muffle chamber prevents ambient air and combustion gases from entering, creating an environment that is effectively oxygen-free and chemically inert.

Facilitating Special Atmospheres

Many advanced muffle furnaces include a port built into the chamber wall.

This port allows for the controlled injection of specific gases, such as nitrogen or argon, to create a completely inert atmosphere. It can also be used for inserting a secondary probe to independently verify the temperature.

Understanding the Trade-offs

While highly effective, the muffle design is a specific engineering choice with inherent trade-offs. It is not the optimal solution for every heating task.

Slower Heating Rates

Indirect heating is less efficient than direct heating. It takes time for the furnace to heat the muffle walls, which then must radiate that heat to the sample.

This results in longer ramp-up times compared to a direct-fire furnace, where the sample is exposed directly to the flame or heating element.

Potential for Minor Temperature Gradients

While a muffle chamber provides excellent uniformity, it is not perfectly uniform. Areas near the door or any monitoring ports may be slightly cooler.

For extremely sensitive processes, the placement of the sample within the chamber is still a factor to consider.

Material Limitations

The chamber itself is typically made of a durable ceramic material designed to withstand extreme thermal stress. However, these materials have a finite lifespan and maximum temperature rating.

Exceeding the furnace's rated temperature can cause the muffle to crack or degrade, compromising its isolating properties and requiring costly repairs.

When Is a Muffle Furnace the Right Choice?

Your specific application will determine if the controlled environment of a muffle chamber is necessary for your goals.

- If your primary focus is material purity and repeatable results: The isolation from contaminants makes the muffle furnace essential for sensitive laboratory work, quality control, and research.

- If your primary focus is a specific chemical reaction: The controlled atmosphere is ideal for processes like ashing, sintering, annealing, or heat-treating materials without oxidation.

- If your primary focus is simply rapid, bulk heating: A direct-fire furnace may be more time and energy-efficient if atmosphere control and absolute uniformity are not critical.

Understanding the role of the muffle chamber empowers you to select the right tool for precise and predictable thermal processing.

Summary Table:

| Feature | Benefit |

|---|---|

| Isolation from heat source | Prevents contamination and ensures material purity |

| Uniform radiant heating | Eliminates hot spots for repeatable, accurate results |

| Controlled atmosphere | Allows inert gas use to prevent oxidation and enable specific reactions |

| Sealed enclosure | Protects samples from combustion gases and ambient air |

Ready to enhance your lab's precision with a custom high-temperature furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for purity, uniformity, and control. Contact us today to discuss how we can support your thermal processing goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?