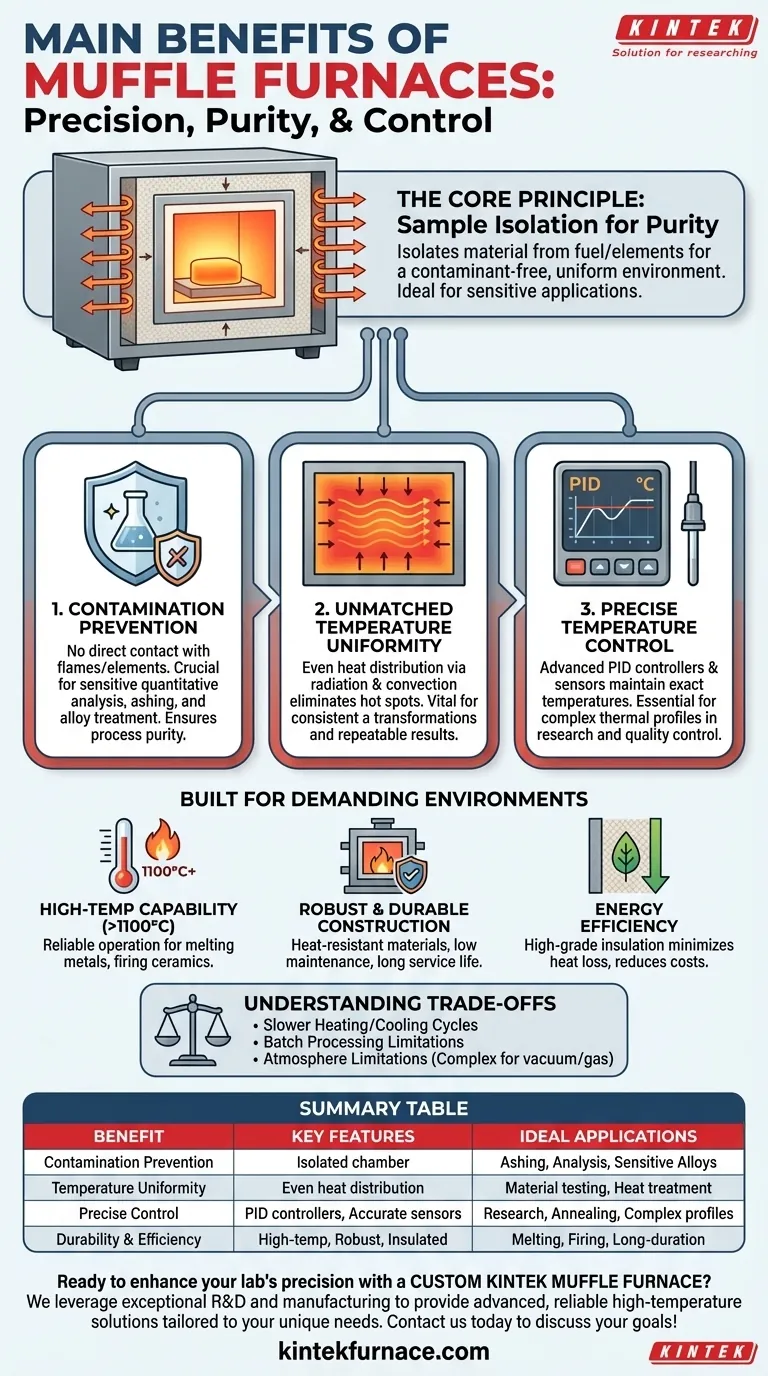

At its core, a muffle furnace provides three primary benefits: exceptional temperature uniformity, precise process control, and the prevention of sample contamination. Its design isolates the material being heated from the fuel source and any combustion byproducts, creating a highly controlled environment ideal for sensitive applications like material testing, ashing, and heat treating.

The defining advantage of a muffle furnace is its ability to create a chemically isolated and thermally uniform environment. This separation between the heating elements and the internal chamber is what ensures process purity and repeatable, accurate results.

The Core Principle: Isolating the Sample for Purity and Precision

The name "muffle" refers to the furnace's inner chamber, which encloses the sample and separates it from the heating elements. This fundamental design is the source of its most critical advantages.

Contamination Prevention

By design, the material inside a muffle furnace never comes into direct contact with flames or the electrical heating elements. This is crucial for processes where even minute contamination from combustion gases or element degradation could compromise the results.

This makes it the standard for applications like quantitative analysis, ashing organic matter, or treating highly sensitive alloys.

Unmatched Temperature Uniformity

The enclosed muffle chamber allows heat to be distributed evenly through both radiation and convection. This eliminates hot spots and ensures the entire sample experiences the same temperature, which is vital for consistent material transformations.

Advanced models utilize multiple heating zones and sophisticated control logic to guarantee uniformity throughout the chamber volume, leading to highly accurate and repeatable test outcomes.

Precise Temperature Control

Modern muffle furnaces use advanced controllers, often with PID (Proportional-Integral-Derivative) auto-tuning capabilities. Paired with sensitive temperature sensors (like J-type thermocouples) and Solid-State Relays (SSRs) for the heaters, this system can maintain a set temperature with extreme accuracy.

This level of control is essential for executing complex thermal profiles required in materials research, quality control, and delicate annealing processes.

Built for Demanding Environments

Beyond precision, muffle furnaces are engineered for durability and efficiency in high-heat, long-duration operations.

High-Temperature Capability

Muffle furnaces are specifically built to operate reliably at very high temperatures, often exceeding 1100°C (2012°F), making them suitable for demanding applications like melting metals, firing ceramics, and advanced material synthesis.

Robust and Durable Construction

These furnaces are constructed from heat-resistant materials that resist oxidation and corrosion. The chamber lining and external insulation, such as high-density glass wool blankets, are designed for maximum thermal efficiency and a long service life with low maintenance costs.

Energy Efficiency

The high-grade insulation minimizes heat loss to the surrounding environment. This not only improves safety by keeping the external surfaces cooler but also significantly reduces energy consumption, making the furnace more cost-effective to operate over its lifetime.

Understanding the Trade-offs

While highly effective, the muffle furnace design comes with inherent trade-offs that are important to consider.

Slower Heating and Cooling Cycles

The same robust insulation that provides excellent thermal efficiency and uniformity also means the furnace takes longer to heat up and cool down. For processes requiring rapid thermal cycling, other types of furnaces might be more suitable.

Batch Processing Limitations

Standard muffle furnaces are designed for batch processing, where a set amount of material is loaded, heated, and then removed. They are less ideal for continuous, high-volume industrial production, where a tunnel furnace might be a better fit.

Atmosphere Limitations

While many muffle furnaces can operate with inert atmospheres like nitrogen or in a vacuum, achieving and maintaining a perfect, high-purity vacuum or specialized gas environment can require more complex and expensive models.

Making the Right Choice for Your Goal

Selecting a muffle furnace depends entirely on the specific requirements of your process.

- If your primary focus is high-purity analysis (e.g., ashing, trace element testing): The key benefit is the muffle's ability to completely prevent contamination of your sample.

- If your primary focus is repeatable material testing (e.g., heat treatment, quality control): The unparalleled temperature uniformity and precise PID control will ensure your results are consistent and reliable.

- If your primary focus is versatile lab heating: The robust design, broad temperature range, and compatibility with various materials make it a durable and flexible workhorse for many applications.

Ultimately, a muffle furnace is the definitive choice when the integrity of your sample and the precision of your thermal process cannot be compromised.

Summary Table:

| Benefit | Key Features | Ideal Applications |

|---|---|---|

| Contamination Prevention | Isolated chamber, no direct contact with heating elements | Ashing, quantitative analysis, sensitive alloys |

| Temperature Uniformity | Even heat distribution, multiple heating zones | Material testing, heat treatment, quality control |

| Precise Temperature Control | PID controllers, SSRs, accurate sensors | Materials research, annealing, complex thermal profiles |

| Durability and Efficiency | High-temperature capability, robust construction, energy-saving insulation | Melting metals, firing ceramics, long-duration operations |

Ready to enhance your lab's precision and efficiency with a custom muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in material testing, ashing, or other sensitive applications, we can deliver reliable, contamination-free performance. Contact us today to discuss how we can support your goals with a bespoke solution!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites