In a laboratory, a muffle furnace is a high-temperature oven primarily used for testing the properties of materials, determining the ash content of a sample, and performing various heat-treatment processes. It provides a precisely controlled, high-heat environment that is isolated from any contaminating byproducts of fuel combustion, ensuring analytical purity.

The core value of a muffle furnace is not just its ability to reach extreme temperatures, but its capacity to do so within an insulated chamber (the "muffle"). This isolates the sample, guaranteeing that the heat applied is pure and free from contaminants that would otherwise skew analytical results or ruin material synthesis.

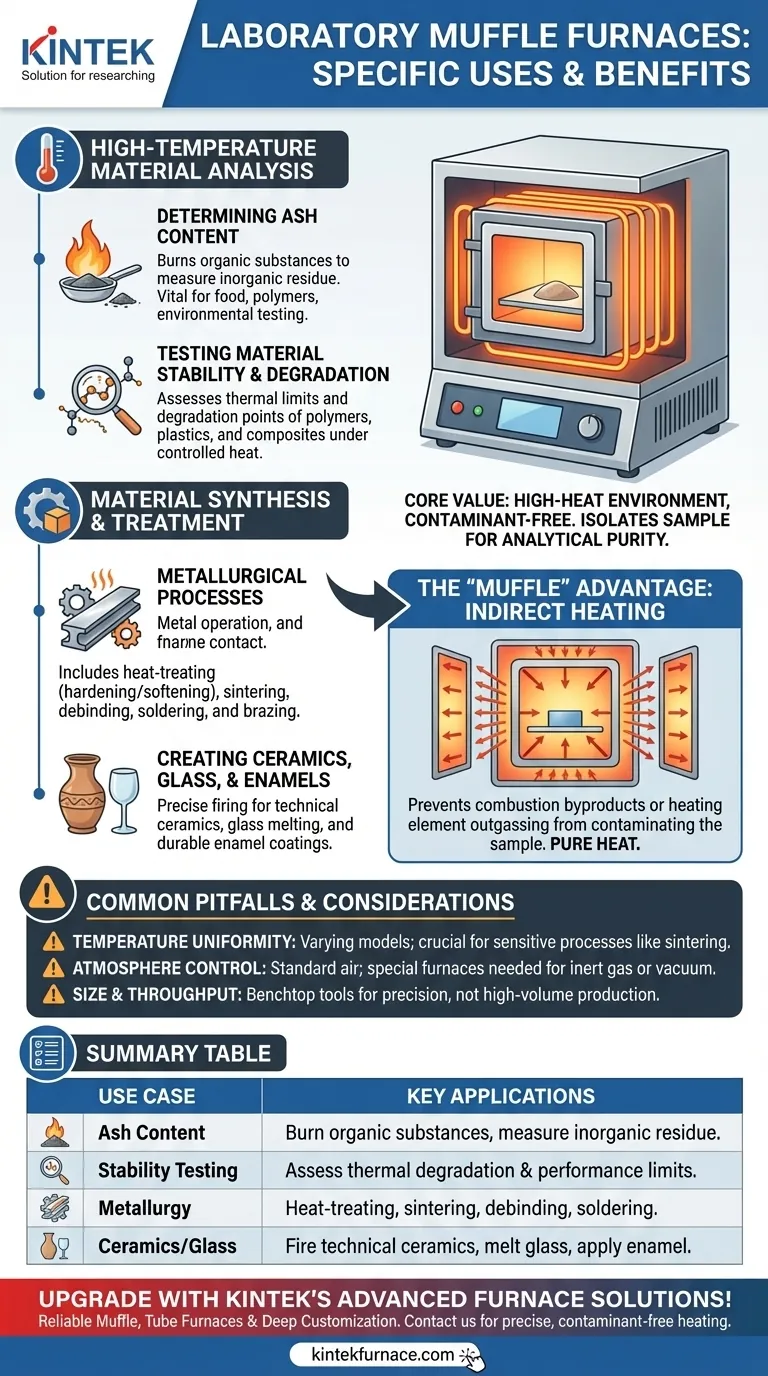

Core Function: High-Temperature Material Analysis

The most common laboratory use of a muffle furnace is to analyze how a material behaves or changes under extreme thermal stress. This provides critical data for quality control, safety, and research.

Determining Ash Content

Ashing is the process of using high heat to burn away all organic substances in a sample, leaving only the non-combustible inorganic residue, or ash. This is a fundamental test in many fields, including food science, polymer analysis, and environmental testing, to determine the mineral or filler content of a material.

The clean heating environment of a muffle furnace is essential for this, as it ensures the final weight of the ash is not altered by external contaminants.

Testing Material Stability and Degradation

Researchers use muffle furnaces to test the thermal stability of materials like polymers, plastics, and composites. By subjecting a sample to controlled high temperatures, they can identify the point of degradation, measure off-gassing, and understand its performance limits in extreme conditions.

Application: Material Synthesis and Treatment

Beyond simple analysis, muffle furnaces are indispensable tools for creating and fundamentally altering materials through heat. This is central to materials science and certain manufacturing processes.

Metallurgical Processes

The high temperatures achievable—often up to 1,800°C (3,272°F)—enable sophisticated metallurgical work. This includes:

- Heat-treating: Altering the physical and mechanical properties of metals, such as hardening or softening steel.

- Sintering: Fusing metallic or ceramic powders together below their melting point to create a solid object.

- Debinding: A critical step in metal injection molding where binder material is burned out of a "green" part before final sintering.

- Soldering and Brazing: Joining metal components at high temperatures.

Creating Ceramics, Glass, and Enamels

Muffle furnaces are used to fire technical ceramics, melt glass for research purposes, and create durable enamel coatings. The precise temperature control and uniform heating are critical for achieving the desired material structure and avoiding defects.

The Key Advantage: The "Muffle" Chamber

The defining feature of this furnace is its name. Understanding the "muffle" is key to understanding its purpose.

The Principle of Indirect Heating

The "muffle" is a sealed, high-temperature chamber that contains the sample. In modern electric furnaces, heating elements surround the outside of this chamber.

Heat is transferred to the sample through conduction, convection, and blackbody radiation, not through direct contact with a flame or heating element.

Why Contamination Control is Critical

This indirect heating design is the furnace's primary advantage. It completely isolates the sample from any potential contaminants produced by the heat source.

In older fuel-fired furnaces, this prevented byproducts of combustion from reacting with the sample. In modern electric furnaces, it prevents any outgassing from the heating elements themselves from affecting the experiment. This purity is non-negotiable for accurate analysis.

Common Pitfalls and Considerations

While powerful, a muffle furnace is a specialized tool with specific limitations that must be understood for proper use.

Temperature Range and Uniformity

Not all muffle furnaces are created equal. Models vary significantly in their maximum temperature and, more importantly, their temperature uniformity across the chamber. For sensitive processes like sintering, poor uniformity can lead to inconsistent results.

Atmosphere Control

A standard muffle furnace operates with a normal air atmosphere inside the chamber. It prevents external contaminants but does not control the atmosphere itself.

For processes that require an inert gas (like argon) or a vacuum to prevent oxidation, a more specialized atmosphere-controlled furnace is required.

Size and Throughput

Laboratory muffle furnaces are relatively small benchtop devices. They are designed for precision and control, not for high-volume industrial production, which limits the size and number of samples that can be processed at one time.

Making the Right Choice for Your Goal

To apply this correctly, align the furnace's capability with your primary objective.

- If your primary focus is quality control or composition analysis: Use the furnace for ash content determination to verify the filler, mineral, or impurity levels in your samples.

- If your primary focus is materials science research: Use the furnace for heat-treating, thermal degradation studies, and testing the properties of novel materials under extreme temperatures.

- If your primary focus is advanced prototyping or synthesis: Use the furnace for creating technical ceramics, sintering powdered metals, and other processes that build or transform a material with high heat.

Ultimately, the muffle furnace is an essential tool for any lab work that demands precise, high-temperature, and contaminant-free heating to understand or create a material.

Summary Table:

| Use Case | Key Applications |

|---|---|

| Ash Content Determination | Burn organic substances to measure inorganic residue in food, polymers, and environmental samples. |

| Material Stability Testing | Assess thermal degradation and performance limits of polymers, plastics, and composites. |

| Metallurgical Processes | Perform heat-treating, sintering, debinding, and soldering for metals. |

| Ceramics and Glass Creation | Fire technical ceramics, melt glass, and apply enamel coatings with uniform heating. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable muffle furnaces, tube furnaces, and more, all backed by strong deep customization to meet your unique experimental needs. Achieve precise, contaminant-free heating for ash analysis, material synthesis, and beyond. Contact us today to discuss how our products can enhance your research and efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing