Input voltage is the single most critical factor for a muffle furnace's performance, safety, and operational lifespan. Supplying the correct voltage is not a guideline but a strict requirement, as a mismatch can lead to immediate equipment failure, inefficient heating, or significant safety hazards in your laboratory.

Matching your furnace's specified voltage to your facility's power supply is a fundamental check for operational integrity. An incorrect voltage directly impacts the power delivered to the heating elements, determining whether the furnace operates as intended or fails catastrophically.

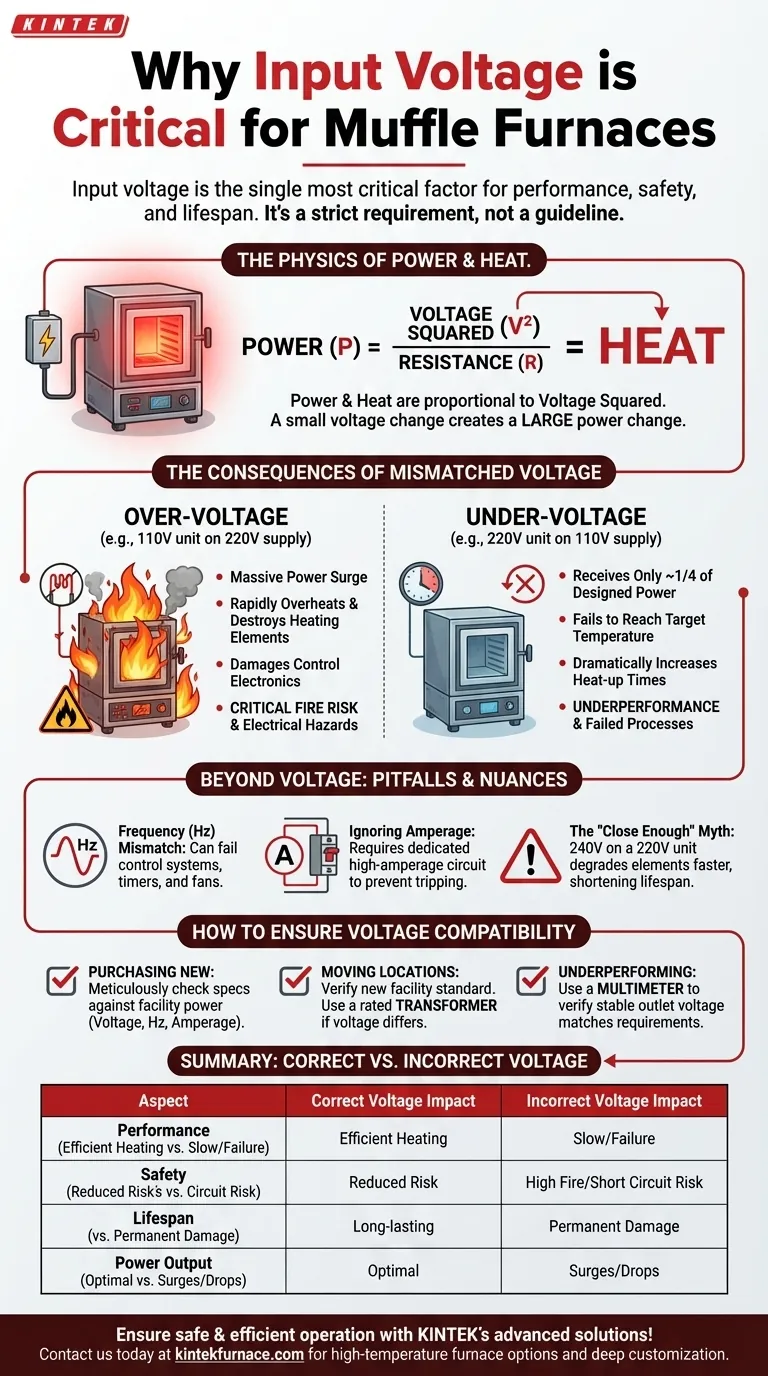

The Physics of Power and Heat

To understand why voltage is so crucial, we must look at the direct relationship between voltage, resistance, and the power that generates heat.

Power Is Proportional to Voltage Squared

A muffle furnace's heating elements have a fixed electrical resistance (R). The power (P) they generate as heat is governed by the formula P = V²/R, where V is the input voltage.

This squared relationship is key. A small change in voltage creates a much larger change in power output.

The Impact of Mismatched Voltage

Because of this exponential relationship, even a modest voltage mismatch has severe consequences:

- Over-voltage: Supplying a voltage higher than the furnace's rating (e.g., plugging a 110V unit into a 220V supply) will cause a massive surge in power. This will rapidly overheat and destroy the heating elements and can damage the control electronics.

- Under-voltage: Supplying a voltage lower than specified will cripple the furnace's heating ability. A 220V furnace connected to a 110V supply will receive only one-quarter (1/4) of its designed power, preventing it from reaching its target temperature or dramatically increasing heat-up times.

Practical Consequences of Incorrect Voltage

Beyond the physics, the real-world implications of a voltage mismatch range from inconvenient to dangerous.

Risk of Permanent Damage

The most common outcome of over-voltage is the permanent burnout of the furnace's core components. This often means a costly and complex repair, replacing the delicate heating coils and potentially the primary power controller.

Underperformance and Failed Processes

An under-powered furnace fails to perform its essential function. This leads to incomplete material processing, inaccurate test results, and wasted time and resources as you wait for the furnace to struggle toward a temperature it may never reach.

Critical Safety Hazards

Over-voltage doesn't just damage the equipment; it creates a serious fire risk. Overwhelmed heating elements and internal wiring can melt, short-circuit, and ignite surrounding materials. It also places immense stress on your facility's electrical circuits.

Understanding the Pitfalls and Nuances

Verifying voltage is the first step, but a truly robust setup requires looking at the complete electrical picture.

Forgetting to Check Frequency (Hz)

While the heating elements themselves are often agnostic to frequency, the furnace's control systems, timers, and cooling fans may be designed for a specific frequency (e.g., 60 Hz in the US vs. 50 Hz in Europe). A mismatch can cause these auxiliary components to fail or run improperly.

Ignoring Amperage and Circuit Capacity

A furnace's nameplate specifies both its required voltage and its current draw (amperage). You must ensure the circuit you plug it into can handle this amperage. A high-power furnace often requires a dedicated, high-amperage circuit and breaker to operate without tripping the power for an entire room.

The "Close Enough" Misconception

Assuming a 220V furnace will work fine on a 240V circuit is a common mistake. While it may function initially, the consistent over-voltage condition will degrade the heating elements faster, significantly shortening the furnace's operational life. Always aim to match the specified voltage as closely as possible.

How to Ensure Voltage Compatibility

Making the right choice is a matter of diligence before you plug in the equipment.

- If you are purchasing a new furnace: Meticulously check the product's technical specifications against your lab's available power outlets. Confirm voltage, frequency, and amperage, and plan for a dedicated circuit if required.

- If you are moving a furnace to a new location: Verify the new facility's power standard. If the voltage differs, you must use a properly rated step-up or step-down transformer to ensure compatibility.

- If your furnace is underperforming: Before assuming a component has failed, use a multimeter to verify the voltage at the outlet is stable and matches the furnace's requirements.

By treating the voltage specification as an absolute requirement, you ensure your equipment runs safely, efficiently, and reliably for its entire lifespan.

Summary Table:

| Aspect | Impact of Correct Voltage | Impact of Incorrect Voltage |

|---|---|---|

| Performance | Efficient heating, accurate temperature control | Slow heating, failure to reach target temperature |

| Safety | Reduced risk of fire and electrical hazards | High risk of overheating, short circuits, and fires |

| Lifespan | Long-lasting components and reliable operation | Permanent damage to heating elements and controls |

| Power Output | Optimal power delivery (P = V²/R) | Power surges or drops leading to inefficiency |

Ensure your muffle furnace operates safely and efficiently with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Don't risk equipment failure—contact us today to discuss how we can enhance your lab's performance and safety!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis