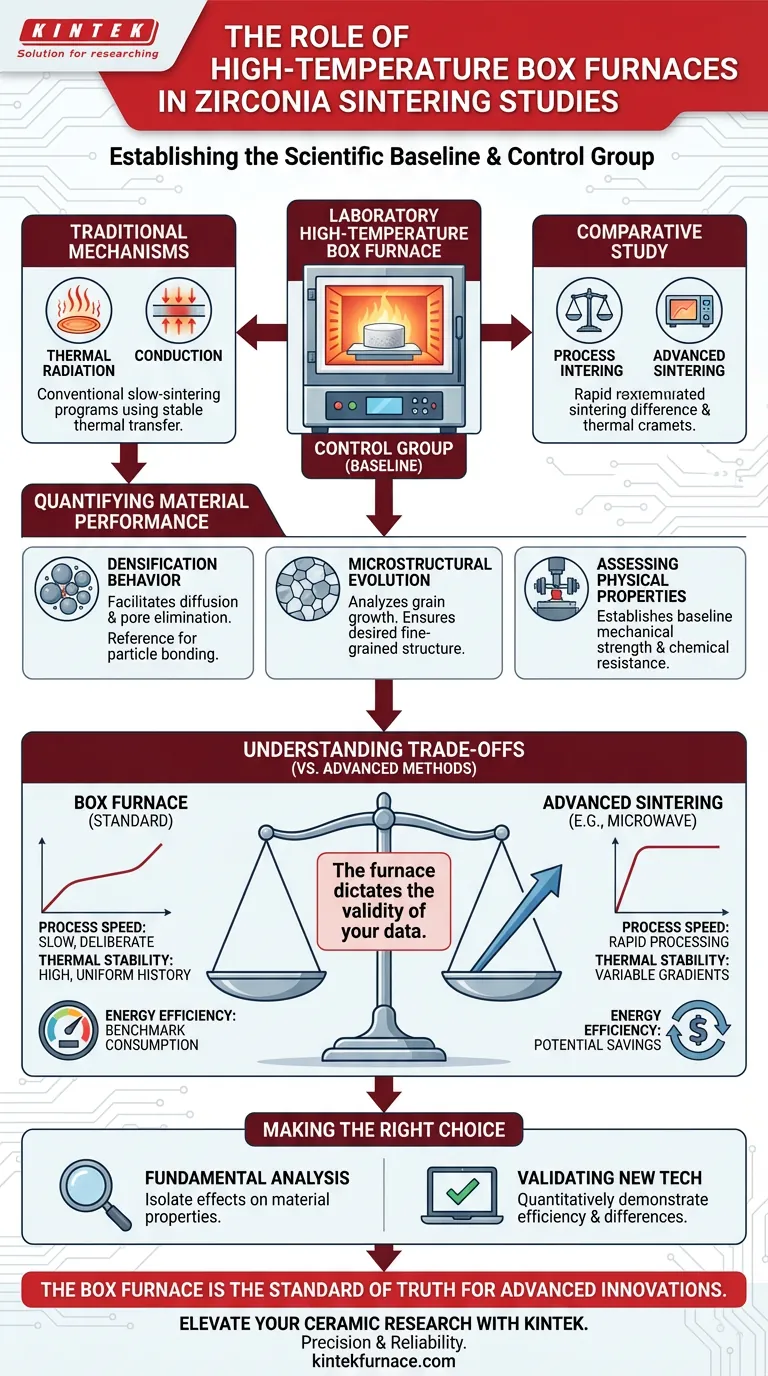

In the context of comparative experimental studies, the laboratory high-temperature box furnace serves as the essential control group. It provides a baseline of stability by utilizing traditional thermal radiation and conduction, allowing researchers to objectively measure the performance deviations of advanced heating methods like microwave sintering.

Experimental accuracy relies on a consistent standard. The high-temperature box furnace provides the conventional slow-sintering baseline required to quantitatively evaluate how different heating mechanisms alter the densification, microstructure, and physical properties of zirconia ceramics.

Establishing the Scientific Baseline

The Role of the Control Group

To determine if a new sintering method is actually superior, you must compare it against a known standard.

The high-temperature box furnace represents this standard. It creates a stable thermal environment using thermal radiation and conduction, the traditional mechanisms for firing ceramics.

Executing Conventional Sintering Programs

Researchers use these furnaces to execute conventional slow-sintering programs.

This process is deliberate and controlled. By adhering to established heating curves, the furnace ensures that any differences observed in the final material are due to the heating mechanism itself, not erratic temperature fluctuations.

Quantifying Material Performance

Evaluating Densification Behavior

The primary goal of sintering is achieving high material density.

The box furnace facilitates the diffusion and bonding of ceramic particles through precise holding times. In a comparative study, this allows researchers to see if faster methods achieve the same level of particle bonding and pore elimination as the traditional approach.

Tracking Microstructural Evolution

The heating method dictates how grains grow within the ceramic.

By using the box furnace as a reference point, scientists can analyze microstructural evolution. They can determine if alternative heating methods lead to abnormal grain growth or if they maintain the desired fine-grained structure typical of controlled, slow sintering.

Assessing Physical Properties

Ultimately, the mechanical strength and chemical resistance of the zirconia define its utility.

The box furnace ensures the complete removal of organic binders and impurities. This produces a baseline sample with established physical properties, against which the hardness and durability of experimentally sintered samples are judged.

Understanding the Trade-offs

Process Speed vs. Thermal Stability

While the box furnace provides high stability, it is inherently slower than advanced methods like microwave sintering.

It relies on heat transferring from the outside of the sample to the inside. This limits the speed of processing but guarantees a uniform thermal history that is difficult to replicate in rapid-heating environments.

Energy Efficiency Considerations

In comparative studies, the box furnace often serves as the benchmark for energy consumption.

While modern heating elements and insulation have improved the efficiency of box furnaces, they are generally used to highlight the potential energy savings of emerging, faster sintering technologies.

Making the Right Choice for Your Goal

When designing your experiment, the choice of furnace dictates the validity of your data.

- If your primary focus is fundamental material analysis: Rely on the high-temperature box furnace to isolate the effects of thermal radiation and conduction on material properties.

- If your primary focus is validating a new technology: Use the box furnace strictly as a control to quantitatively demonstrate the efficiency gains or microstructural differences of your novel method.

The box furnace is not just a heating tool; it is the standard of truth against which all advanced sintering innovations must be measured.

Summary Table:

| Feature | High-Temperature Box Furnace (Control) | Advanced Sintering (e.g., Microwave) |

|---|---|---|

| Heating Mechanism | Thermal radiation and conduction | Volumetric/Electromagnetic heating |

| Process Speed | Slow, deliberate heating curves | Rapid processing |

| Thermal Stability | High; uniform thermal history | Variable; potential for thermal gradients |

| Primary Role | Scientific baseline for comparison | Experimental validation of new tech |

| Material Impact | Standard grain growth & densification | Altered microstructure & grain size |

Elevate Your Ceramic Research with KINTEK

Precision in material science begins with a reliable thermal baseline. KINTEK provides industry-leading high-temperature box furnaces, engineered to deliver the stability and accuracy required for rigorous comparative studies.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are conducting fundamental zirconia research or validating next-generation sintering technologies, our laboratory high-temp furnaces are fully customizable to meet your unique experimental needs.

Ready to achieve superior consistency in your lab? Contact us today to find your perfect furnace solution!

Visual Guide

References

- Dilsuz A. Abdaljabar, Ahmed Abdulrasool Ahmed Alkhafaji. Using Taguchi Technique to Study the Effect of Adding Copper Nano on Shape Recovery for Smart Alloy (CU-AL-NI). DOI: 10.31026/j.eng.2025.05.03

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does the heating process work in a muffle furnace? Discover Clean, Uniform Heating for Your Lab

- How does a muffle furnace control the atmosphere around the sample? Achieve Precise Material Processing

- What maintenance practices are recommended for a muffle furnace? Ensure Longevity and Safety in Your Lab

- What is the primary function of a laboratory oven during the initial processing of geopolymer samples? Expert Guide

- What makes box furnaces suitable for demanding applications? Engineered for Precision and Durability in High-Stakes Processes

- Why is it necessary to use a preheating furnace for SiC and B4C? Ensure Safety and Quality in Magnesium Composites

- What are the industrial uses of a muffle furnace? Enhance Precision and Purity in High-Temp Applications

- What are the power requirements for the muffle furnace? Ensure Safe and Efficient Operation