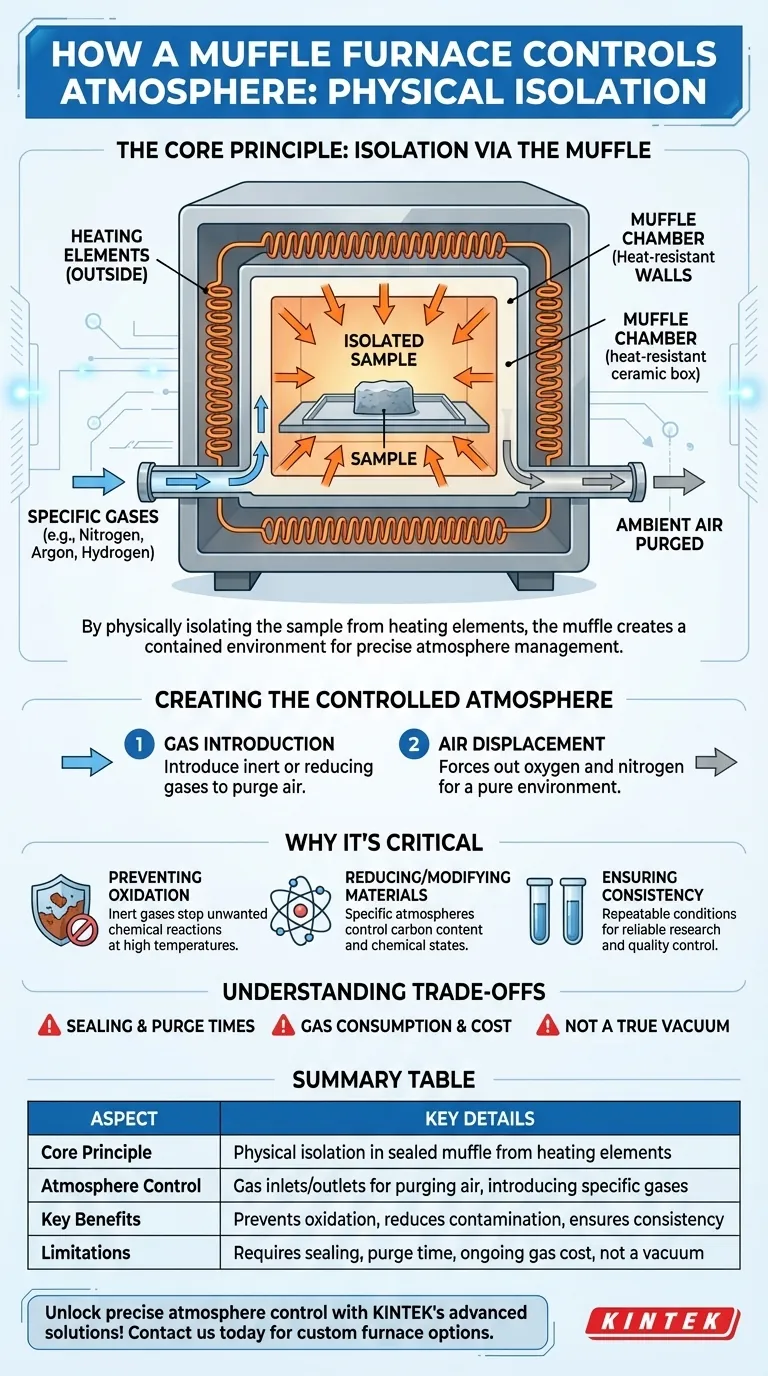

At its core, a muffle furnace controls atmosphere by physically isolating the sample from the heating source. It uses a sealed inner chamber, known as the "muffle," which contains the material being heated. This design creates a self-contained environment, allowing you to introduce specific gases and purge the ambient air without interference from the heating elements or external contaminants.

The furnace's ability to control atmosphere hinges on a single design principle: physical isolation. By placing the sample inside a sealed chamber (the 'muffle') that is separate from the heating elements, the furnace creates a contained environment where the atmosphere can be precisely managed without contamination.

The Core Principle: Isolation via the Muffle

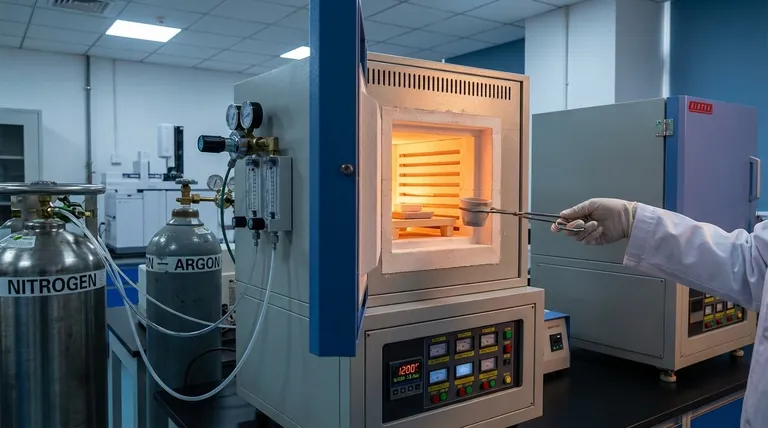

To truly understand atmosphere control, you must first understand the furnace's fundamental architecture. The "muffle" is the key to the entire process.

What is a "Muffle"?

A muffle is a box-like chamber made of a refractory (heat-resistant) ceramic material. Your sample is placed inside this box.

The heating elements of the furnace are located outside of the muffle, heating it from the exterior. The muffle then radiates this heat inward, ensuring the sample is heated evenly.

Separating Heating from Environment

This separation is the most critical feature. In simpler furnaces, the heating elements are in the same space as the sample, meaning they can react with or shed particles onto the material.

By isolating the sample, the muffle design ensures that the only things inside the chamber are the sample and the atmosphere you choose to create. It prevents contamination from combustion byproducts or the heating elements themselves.

Creating the Controlled Atmosphere

With the sample isolated, controlling the atmosphere becomes a straightforward process. The muffle chamber is equipped with gas inlets and outlets.

A specific gas, such as nitrogen, argon, hydrogen, or a gas mixture, is fed into the chamber through the inlet. This incoming gas purges the original air (mostly oxygen and nitrogen) and forces it out through the outlet.

Once the ambient air is displaced, the chamber is filled with a known, controlled atmosphere that can be maintained throughout the heating process.

Why Atmosphere Control is Critical

Managing the atmosphere isn't just an optional feature; for many advanced material processing and analytical tasks, it is an absolute requirement.

Preventing Unwanted Oxidation

Many materials react with oxygen at high temperatures, a process called oxidation. This can ruin a sample, alter its properties, or invalidate an experiment.

By filling the muffle with an inert gas like nitrogen or argon, you remove the oxygen and create an environment where these unwanted chemical reactions cannot occur.

Reducing or Modifying Materials

For some processes, a reducing atmosphere using gases like hydrogen is necessary. This can be used to remove oxygen from a compound or achieve a specific chemical state.

Similarly, specific atmospheres can be used to control carbon content, preventing the unwanted carbonization or decarburization of a sample.

Ensuring Process Consistency

A controlled atmosphere ensures that every sample is processed under identical conditions. This repeatability is essential for scientific research, quality control, and manufacturing, where even small variations can lead to different outcomes.

Understanding the Trade-offs

While powerful, this method of atmosphere control has practical considerations and limitations that you must be aware of.

Sealing and Purge Times

The effectiveness of the controlled atmosphere depends entirely on the quality of the seal on the furnace door. Any leaks will allow ambient air to contaminate the chamber.

Furthermore, purging the chamber of all ambient air is not instantaneous. It requires a sufficient flow of the desired gas for a specific period before the heating cycle begins to ensure a pure environment.

Gas Consumption and Cost

Maintaining a controlled atmosphere requires a continuous supply of gas, which represents an ongoing operational cost. For processes requiring long durations or high gas-flow rates, this can be a significant expense.

Not a True Vacuum

A standard muffle furnace displaces air with another gas; it does not create a hard vacuum. While it can effectively reduce oxygen to very low levels, it is not a substitute for a dedicated vacuum furnace if your process requires a near-complete absence of all gas molecules.

Making the Right Choice for Your Process

Applying this knowledge depends on your specific goal. The right atmospheric approach is determined by the material you are working with and your desired outcome.

- If your primary focus is preventing oxidation: Use an inert gas like nitrogen or argon to thoroughly purge the chamber before and during heating.

- If your primary focus is material purity: The muffle's isolation is your greatest asset, as it protects your sample from any contamination from the heating elements.

- If your primary focus is simple high-temperature heating in air: Atmosphere control is not necessary, but you still benefit from the muffle's ability to provide highly uniform, radiant heat.

Understanding this principle of isolation empowers you to select and operate the right equipment for achieving precise, repeatable results in your work.

Summary Table:

| Aspect | Key Details |

|---|---|

| Core Principle | Physical isolation of sample in a sealed muffle chamber, separate from heating elements |

| Atmosphere Control | Gas inlets/outlets for purging air and introducing inert or reducing gases (e.g., nitrogen, argon, hydrogen) |

| Key Benefits | Prevents oxidation, reduces contamination, ensures process consistency and repeatability |

| Limitations | Requires good sealing, purge time, ongoing gas costs, and does not create a vacuum |

Unlock precise atmosphere control for your lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can tailor solutions to your unique experimental needs, enhancing efficiency and accuracy. Contact us today to discuss how we can support your material processing goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?