Preheating reinforcement particles is a fundamental requirement for the safe and effective fabrication of magnesium-based composites. By heating Silicon Carbide (SiC) and Boron Carbide (B4C) micro-powders to approximately 200°C, you actively strip away adsorbed moisture and volatile impurities. This prevents dangerous reactions and prepares the particle surface for optimal interaction with the magnesium matrix.

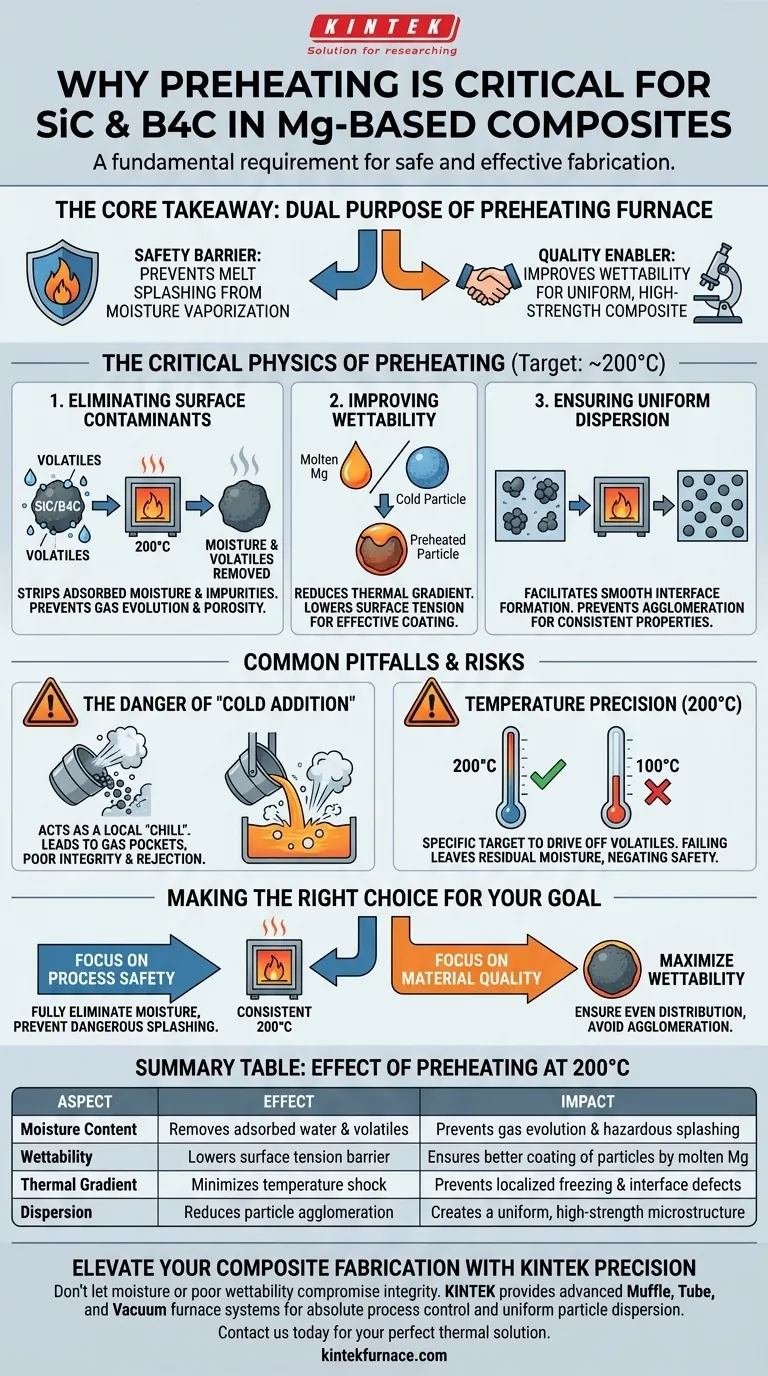

Core Takeaway The preheating furnace serves a critical dual purpose: it acts as a safety barrier by preventing melt splashing caused by moisture vaporization, and it functions as a quality enabler by improving wettability to ensure a uniform, high-strength composite.

The Critical Physics of Preheating

To understand why this step is non-negotiable, you must look at the interaction between the ceramic reinforcement and the molten metal.

Eliminating Surface Contaminants

Micro-powders like SiC and B4C have large surface areas that naturally attract and hold adsorbed moisture and volatile impurities from the atmosphere.

If these particles are introduced into the magnesium melt cold, the trapped moisture instantly turns into steam.

This rapid expansion causes gas evolution, leading to porosity in the final material and dangerous splashing of the molten metal.

Improving Wettability

Magnesium does not naturally "wet" ceramic particles easily.

Preheating the particles significantly reduces the temperature difference between the reinforcement phase and the magnesium melt.

This thermal alignment lowers the surface tension barrier, allowing the molten magnesium to coat the particles more effectively.

Ensuring Uniform Dispersion

When wettability is poor, particles tend to clump together or float, creating weak points in the composite.

By preheating, you facilitate a smoother interface formation.

This ensures the SiC and B4C particles are uniformly dispersed throughout the matrix, which is essential for consistent mechanical properties.

Common Pitfalls and Risks

While the concept is simple, failing to execute this step correctly leads to immediate processing failures.

The Danger of "Cold Addition"

Skipping the preheating furnace is the most common cause of casting defects.

Adding cold particles acts as a local "chill" on the melt, freezing the magnesium at the interface before a bond can form.

This results in a composite with poor structural integrity and high rejection rates due to trapped gas pockets.

Temperature Precision

The target temperature of 200°C is specific and intentional.

It is high enough to drive off volatiles but low enough to be easily manageable within a standard production environment.

Failing to reach this temperature threshold leaves residual moisture, negating the safety benefits of the process.

Making the Right Choice for Your Goal

To achieve the best results in fabricating magnesium-based composites, apply these principles:

- If your primary focus is Process Safety: Ensure your furnace creates a consistent 200°C environment to fully eliminate moisture and prevent molten metal splashing.

- If your primary focus is Material Quality: View preheating as a tool to maximize wettability, ensuring the reinforcement particles are evenly distributed rather than agglomerated.

Ultimately, the preheating furnace is not just a drying step; it is the bridge that allows dissimilar materials—ceramic and metal—to combine into a high-performance composite.

Summary Table:

| Aspect | Effect of Preheating at 200°C | Impact on Final Composite |

|---|---|---|

| Moisture Content | Removes adsorbed water & volatiles | Prevents gas evolution and hazardous splashing |

| Wettability | Lowers surface tension barrier | Ensures better coating of particles by molten Mg |

| Thermal Gradient | Minimizes temperature shock | Prevents localized freezing and interface defects |

| Dispersion | Reduces particle agglomeration | Creates a uniform, high-strength microstructure |

Elevate Your Composite Fabrication with KINTEK Precision

Don't let moisture or poor wettability compromise your material integrity. At KINTEK, we understand that high-performance magnesium-based composites require absolute process control. Our expert R&D and manufacturing teams provide advanced Muffle, Tube, and Vacuum furnace systems—all fully customizable to meet your specific temperature and atmospheric requirements.

Whether you are refining SiC/B4C preheating protocols or scaling up production, KINTEK offers the specialized lab high-temp furnaces needed to ensure safety and uniform particle dispersion. Contact us today to find the perfect thermal solution for your unique needs.

Visual Guide

References

- N. Srilatha, Abhinav Cheruku. Investigating the influence of SiC and B <sub>4</sub> C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites. DOI: 10.1515/jmbm-2025-0061

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role do muffle furnaces play in materials research? Unlock Precise Heat Treatment for Your Lab

- How does the heating process work in a muffle furnace? Discover Clean, Uniform Heating for Your Lab

- How does the programmed temperature control of a muffle furnace influence the formation of g-C3N4 semiconductors?

- Which industries utilize Box Furnaces? The Essential Tool for Industrial Heat Treatment

- What is the mechanism of a box muffle furnace in the preparation of active magnesium oxide powder? Expert Guide

- What role does a laboratory high-temperature muffle furnace play in the treatment of highly contaminated waste glass?

- What role does a laboratory muffle furnace play in the determination of phosphorus content? Essential Dry Ashing Guide

- What types of materials can be analyzed using a muffle furnace? Unlock Precise Thermal Analysis for Diverse Samples