In materials research, a muffle furnace serves as a high-temperature oven that provides a precisely controlled and isolated thermal environment. Its fundamental role is to enable the synthesis, heat treatment, and analysis of materials by subjecting them to extreme heat without contamination from combustion byproducts or uncontrolled atmospheric reactions.

The core value of a muffle furnace is its ability to create a clean, uniform, and stable high-temperature environment. This ensures that changes observed in a material are a direct result of the applied heat, not from external contaminants, leading to reliable and reproducible experimental outcomes.

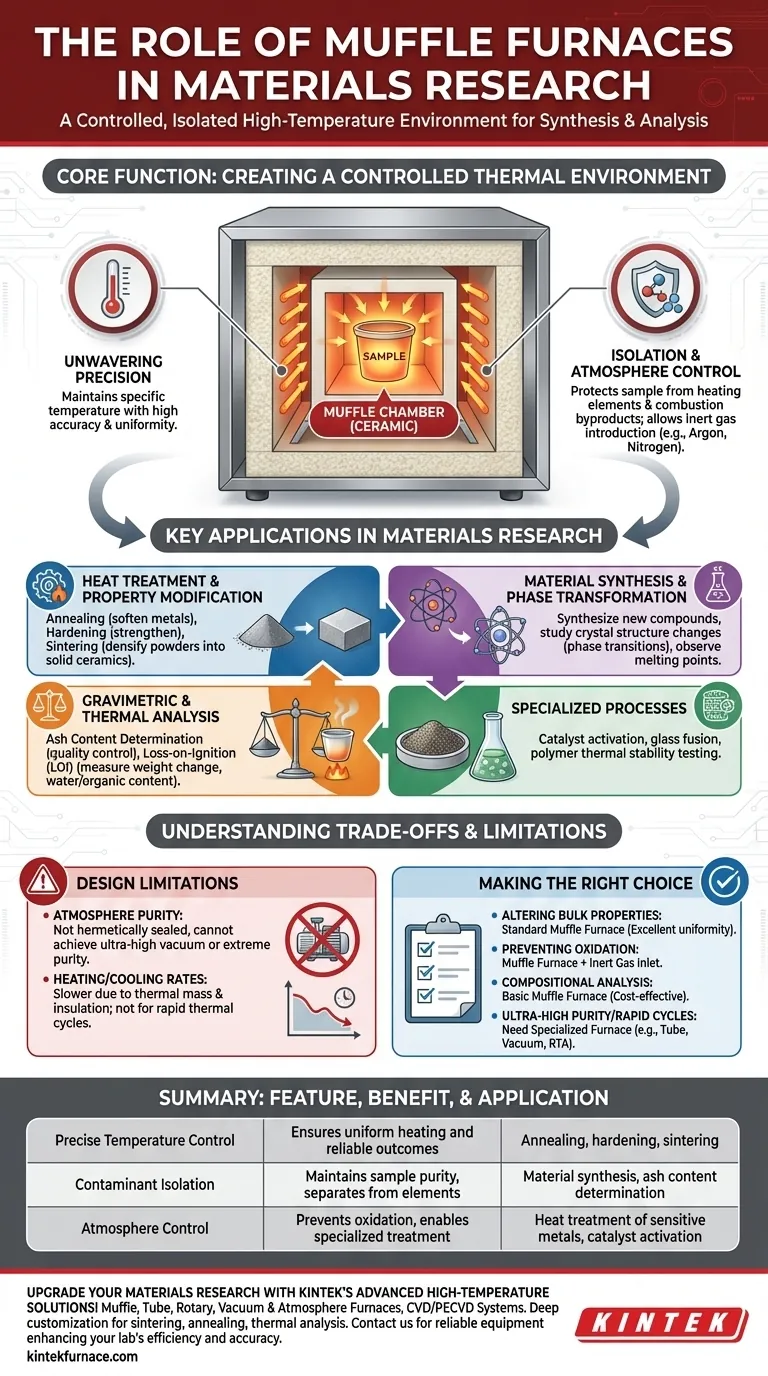

The Core Function: Creating a Controlled Thermal Environment

The name "muffle furnace" comes from its key design feature: the muffle. This is an inner chamber, typically made of high-temperature ceramic, that isolates the material being tested from the heating elements. This separation is the source of its primary benefits.

Unwavering Temperature Precision

A muffle furnace is engineered to achieve and maintain a specific temperature with high accuracy and uniformity throughout its chamber.

This stability is critical for processes where slight temperature deviations can drastically alter a material's final properties or compromise experimental results.

Isolation from Contaminants

The muffle acts as a physical barrier between the sample and the heating elements. In fuel-fired furnaces, this prevents byproducts of combustion from contaminating the sample.

In electric furnaces, it protects sensitive materials from any potential off-gassing from the heating elements themselves, ensuring the sample's chemical purity is maintained.

Atmosphere Control

Many modern muffle furnaces allow for the introduction of a controlled atmosphere, such as an inert gas like argon or nitrogen.

This capability is essential for heat-treating materials that readily oxidize or react with air at high temperatures, such as certain metals and advanced alloys.

Key Applications in Materials Research

By providing this controlled environment, muffle furnaces unlock a wide range of essential research processes.

Heat Treatment and Property Modification

This is one of the most common applications. Processes like annealing (softening metals), hardening (strengthening them), and sintering (fusing powders into a dense solid) are used to precisely engineer a material's mechanical properties.

Ceramics, for example, are densified through sintering in a muffle furnace to achieve their characteristic hardness and durability.

Material Synthesis and Phase Transformation

Researchers use muffle furnaces to synthesize new compounds or study phase transformations—how a material’s crystal structure changes as it is heated and cooled.

Observing a material's melting point or its transition from one crystalline state to another provides fundamental data about its nature.

Gravimetric and Thermal Analysis

Muffle furnaces are workhorses for analytical testing. Ash content determination, which involves burning off all organic matter to weigh the inorganic residue, is a standard quality control test.

Similarly, Loss-on-Ignition (LOI) testing measures the weight change in a sample after being heated to a high temperature, often to determine its water or organic content.

Specialized Processes

The versatility of muffle furnaces extends to other niche applications, including activating catalysts for chemical reactions, fusing glass components, and testing the thermal stability and degradation of polymers and plastics.

Understanding the Trade-offs and Limitations

While incredibly useful, a muffle furnace is not the right tool for every thermal application. Understanding its design limitations is key to good science.

The "Muffle" Design Principle

The furnace is built around the muffle chamber. The outer housing is typically stainless steel, with layers of high-density fiber insulation to minimize heat loss and maintain a safe external temperature. High-power electric heating elements surround the muffle to provide the heat.

Limitation: Atmosphere Purity

While many furnaces offer gas purging to create an inert atmosphere, they are not hermetically sealed. They cannot achieve the ultra-high vacuum or extreme gas purity levels of more specialized systems like vacuum furnaces or dedicated tube furnaces. For exquisitely sensitive materials, a muffle furnace may not be sufficient.

Limitation: Heating and Cooling Rates

Due to their significant thermal mass and heavy insulation, muffle furnaces generally have slower heating and cooling rates compared to systems like Rapid Thermal Annealing (RTA) furnaces. Experiments requiring extremely fast thermal cycles are not a good fit for a standard muffle furnace.

Making the Right Choice for Your Goal

Selecting the right thermal processing tool depends entirely on your experimental objective.

- If your primary focus is altering bulk properties like hardness or density (annealing, sintering): A standard muffle furnace is the ideal tool due to its excellent temperature uniformity.

- If your primary focus is preventing oxidation of sensitive metals: A muffle furnace equipped with an inert gas inlet is essential for your work.

- If your primary focus is simple compositional analysis (ashing, LOI): A basic, reliable muffle furnace is a cost-effective and indispensable laboratory instrument.

- If your primary focus requires ultra-high purity, vacuum conditions, or very rapid heating: A muffle furnace is likely insufficient; you should consider a specialized tube furnace, vacuum furnace, or RTA system.

Ultimately, mastering the muffle furnace is about leveraging its power for controlled, clean, and stable heating while respecting its inherent design limitations.

Summary Table:

| Feature | Benefit | Common Applications |

|---|---|---|

| Precise Temperature Control | Ensures uniform heating and reliable experimental outcomes | Annealing, hardening, sintering |

| Contaminant Isolation | Maintains sample purity by separating from heating elements | Material synthesis, ash content determination |

| Atmosphere Control | Prevents oxidation with inert gases like argon or nitrogen | Heat treatment of sensitive metals, catalyst activation |

Upgrade your materials research with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for processes such as sintering, annealing, and thermal analysis. Contact us today to discuss how our solutions can enhance your lab's efficiency and accuracy!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production