At its core, a muffle furnace operates by using electric heating elements to heat an isolated inner chamber. This design ensures the material inside, or the "workpiece," is heated uniformly through a combination of thermal radiation and convection, without being directly exposed to the heating elements or any potential contaminants.

The defining principle of a muffle furnace is not just its ability to generate high temperatures, but its method of creating an ultra-clean and precisely controlled heating environment by physically isolating the sample from the actual heat source.

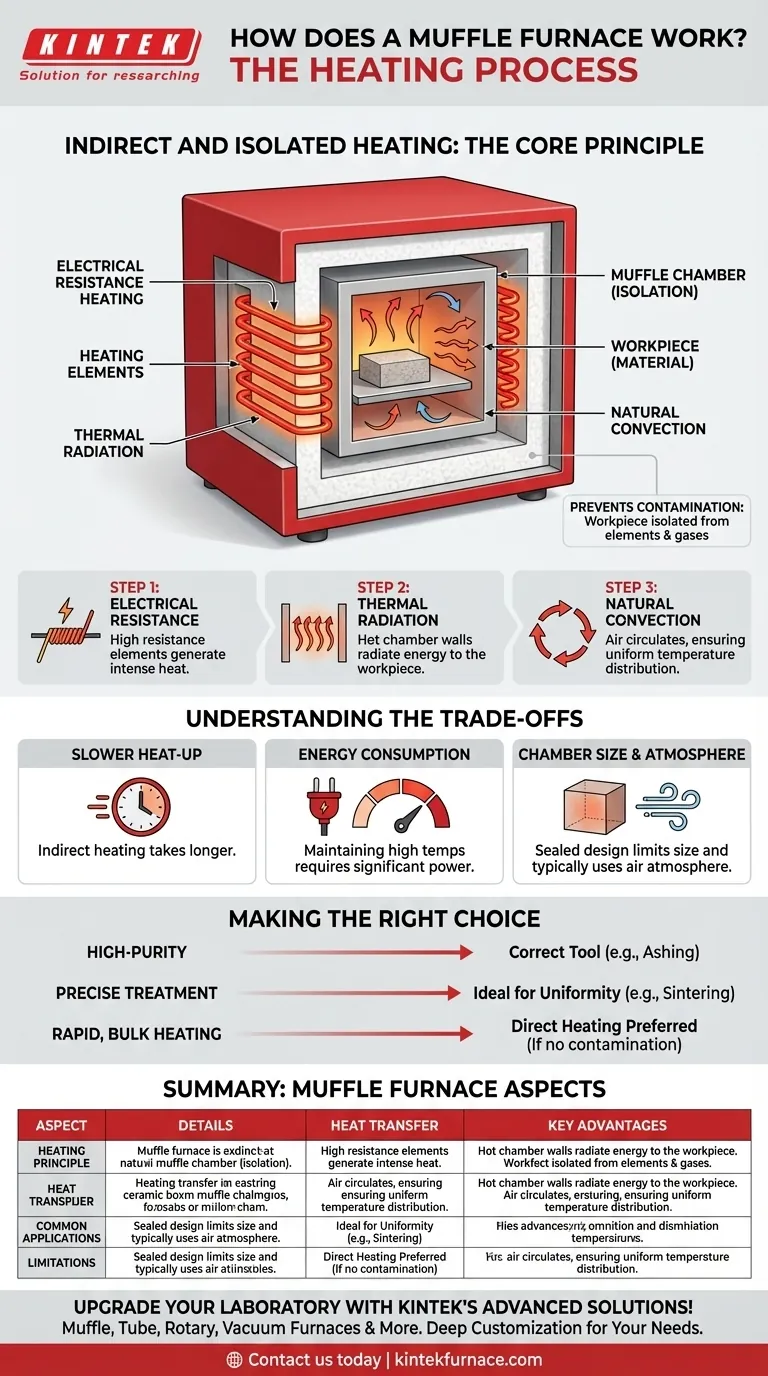

The Core Principle: Indirect and Isolated Heating

The term "muffle" refers to the furnace's key design feature: a separated, enclosed chamber that muffles the workpiece from the raw energy source. This approach is fundamentally different from a conventional furnace where a material might be exposed directly to a flame.

The Role of the "Muffle" Chamber

The muffle itself is a box-like chamber, typically made of high-temperature-resistant ceramic materials like alumina. It acts as the container for the samples being heated.

Heating elements are wrapped around the outside of this muffle chamber. They heat the chamber walls, not the air or the sample directly.

Preventing Contamination

This separation is the furnace's primary advantage. By isolating the workpiece, it prevents any contamination from combustion gases (in older fuel-fired models) or from particles flaking off the electric heating elements.

This makes the muffle furnace essential for sensitive analytical processes like ashing or gravimetric analysis, where the purity of the final sample is critical.

How Heat is Generated and Transferred

The heating process occurs in a precise, multi-stage sequence that ensures the entire chamber reaches a stable and uniform temperature.

Step 1: Electrical Resistance Heating

Modern muffle furnaces use heating elements made from materials with high electrical resistance, such as nichrome, kanthal, or silicon carbide wires.

When a high electrical current is passed through these elements, their resistance causes them to become extremely hot, generating the initial thermal energy.

Step 2: Thermal Radiation

The intensely hot heating elements radiate thermal energy, which is absorbed by the outer walls of the muffle chamber. The chamber walls, in turn, become uniformly hot and radiate this heat inward.

This thermal radiation transfers heat directly to the surface of the workpiece inside the chamber, much like the sun warms the earth.

Step 3: Natural Convection

As the air inside the sealed muffle chamber is heated by the hot walls, it begins to circulate. Hotter, less dense air rises, and cooler, denser air sinks.

This continuous circulation, known as natural convection, helps distribute the heat evenly throughout the chamber, ensuring the entire workpiece reaches the target temperature.

Understanding the Trade-offs

While powerful, the design of a muffle furnace presents specific limitations that are important to understand for its proper application.

Slower Heat-Up Times

Because the heating is indirect—from element to chamber wall to workpiece—muffle furnaces generally take longer to reach their target temperature compared to direct-heating methods.

Energy Consumption

Maintaining very high temperatures (often >1000°C) inside a well-insulated box requires a significant and continuous input of electrical energy. The excellent insulation that holds the heat also means they can be slow to cool down.

Chamber Size and Atmosphere

The sealed, isolated design limits the size of the workpieces that can be processed. Furthermore, standard muffle furnaces operate in an air atmosphere; modifying them for inert or reactive gas atmospheres requires more complex and expensive designs.

Making the Right Choice for Your Application

Choosing to use a muffle furnace depends entirely on whether your process demands its unique benefits of purity and uniformity.

- If your primary focus is high-purity sample treatment: The muffle furnace is the correct tool, as its isolated chamber is specifically designed to prevent contamination during processes like ashing or materials synthesis.

- If your primary focus is precise material heat treatment: The furnace's excellent temperature uniformity and digital control make it ideal for processes like annealing, tempering, or sintering metals and ceramics.

- If your primary focus is simply rapid, bulk heating: A different type of oven or furnace that uses direct heating may be a more time- and energy-efficient choice, provided sample contamination is not a concern.

By understanding the principle of indirect, isolated heating, you can leverage the muffle furnace for applications that demand the highest levels of thermal precision and purity.

Summary Table:

| Aspect | Details |

|---|---|

| Heating Principle | Indirect heating via electric elements outside the muffle chamber |

| Heat Transfer | Thermal radiation and natural convection for uniform temperature |

| Key Advantages | Prevents contamination, ensures precise control, ideal for sensitive processes |

| Common Applications | Ashing, gravimetric analysis, annealing, sintering, materials synthesis |

| Limitations | Slower heat-up times, higher energy use, limited chamber size |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for contamination-free and uniform heating. Contact us today to discuss how our furnaces can enhance your research and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production