In short, a box furnace's suitability for demanding applications comes from a combination of robust physical construction, advanced thermal management, and highly uniform heating. These elements work together to create a stable, predictable, and repeatable operating environment, which is the primary requirement for any high-stakes thermal process.

The key takeaway is not simply that box furnaces get hot, but that they are engineered to maintain precise, uniform, and reliable temperatures under stress. This focus on stability and durability is what separates them from standard equipment and makes them dependable for critical laboratory and industrial work.

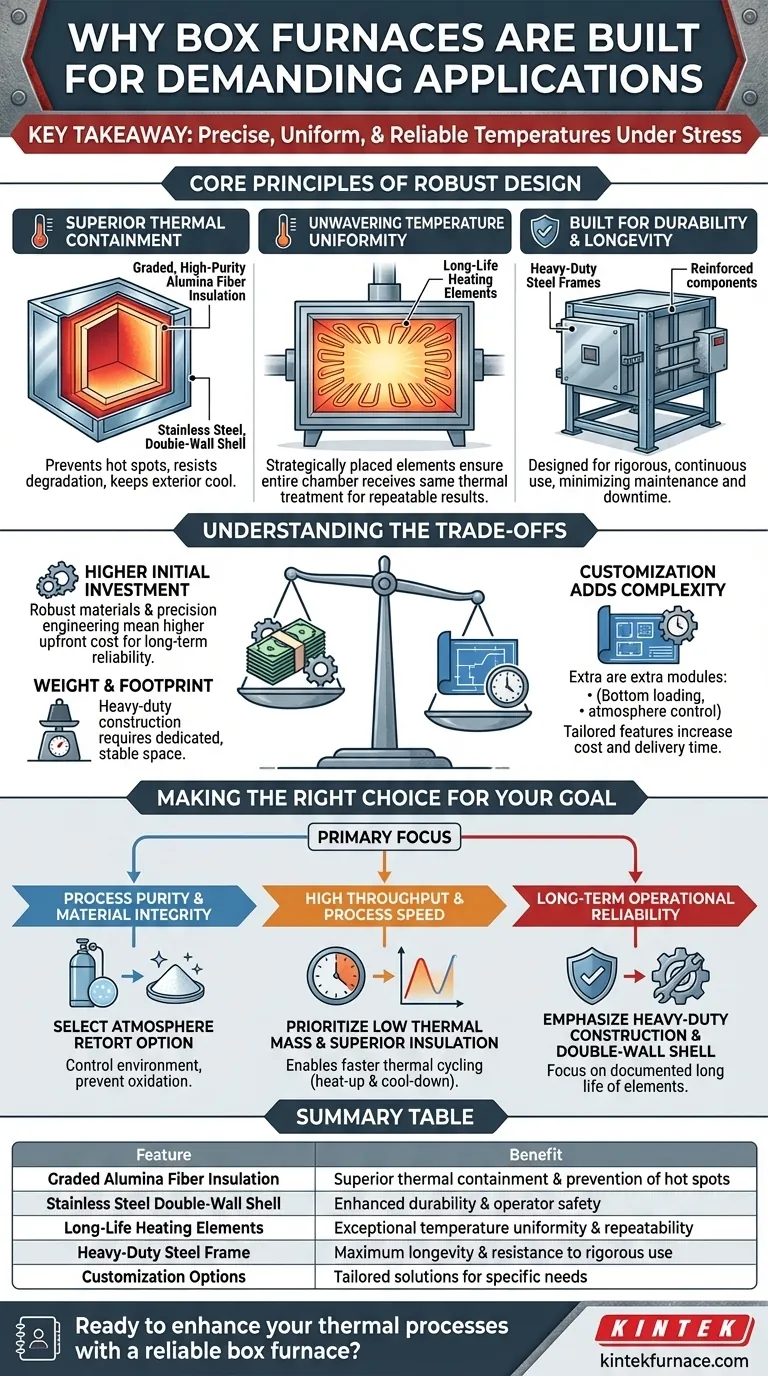

The Core Principles of Robust Furnace Design

A demanding application—whether in materials science, metallurgy, or quality control—is defined by its intolerance for error. The design of a high-performance box furnace directly addresses this by focusing on three foundational principles.

Superior Thermal Containment

The first priority is keeping the heat precisely where it needs to be: inside the chamber.

This is achieved through a graded, high-purity alumina fiber insulation system. Unlike single-layer insulation, this layered approach is engineered to resist degradation and prevent "hot spots" from forming, even at extreme temperatures.

The insulation is housed within a stainless steel, double-wall shell. This heavy-duty construction not only provides exceptional durability but also keeps the exterior of the furnace cool to the touch, ensuring operator safety and stability.

Unwavering Temperature Uniformity

For processes like annealing or sintering, temperature variations of even a few degrees can ruin a sample.

High-performance box furnaces utilize long-life heating elements that are strategically placed to deliver exceptional temperature uniformity across the entire chamber. This ensures that every part of your sample or batch receives the exact same thermal treatment.

This uniformity is the cornerstone of repeatable and reliable results, which is non-negotiable in research and production environments.

Built for Durability and Longevity

Downtime in a demanding application is costly. The construction of these furnaces is designed to maximize operational life and minimize maintenance.

The combination of heavy-duty steel frames, high-quality insulation that resists degradation, and long-life elements means the furnace is built to withstand rigorous, continuous use. This translates to a higher return on investment and greater operational confidence.

Understanding the Trade-offs

While highly capable, it is important to understand the inherent trade-offs that come with this level of performance.

Higher Initial Investment

The robust materials and precision engineering—from the graded insulation to the advanced heating elements—result in a higher upfront cost compared to lighter-duty or standard laboratory furnaces. This is a classic trade-off between initial cost and long-term reliability.

Weight and Footprint

Heavy-duty construction inherently means more weight. While the low thermal conductivity of the insulation allows for some weight reduction compared to older brick-lined furnaces, these are not lightweight, portable devices. They require a dedicated, stable space.

Customization Adds Complexity and Lead Time

While the ability to customize for features like bottom loading or atmosphere control is a major advantage, it also adds to the cost and delivery time. A highly specialized furnace requires more detailed planning and a longer manufacturing cycle than a standard, off-the-shelf model.

Making the Right Choice for Your Goal

Your specific application should dictate which features you prioritize.

- If your primary focus is process purity and material integrity: You must select a model with an atmosphere retort option to control the internal environment and prevent oxidation.

- If your primary focus is high throughput and process speed: Prioritize a furnace with low thermal mass and superior insulation, as this enables faster thermal cycling (heat-up and cool-down).

- If your primary focus is long-term operational reliability: Emphasize the heavy-duty construction, double-wall shell, and documented long life of the heating elements.

Ultimately, choosing the right furnace is about matching the engineering principles of the equipment to the non-negotiable demands of your work.

Summary Table:

| Feature | Benefit |

|---|---|

| Graded Alumina Fiber Insulation | Superior thermal containment and prevention of hot spots |

| Stainless Steel Double-Wall Shell | Enhanced durability and operator safety |

| Long-Life Heating Elements | Exceptional temperature uniformity and repeatability |

| Heavy-Duty Steel Frame | Maximum longevity and resistance to rigorous use |

| Customization Options (e.g., Atmosphere Control) | Tailored solutions for specific application needs |

Ready to enhance your thermal processes with a reliable box furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for demanding applications. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our durable and precise furnaces can optimize your lab's efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the role of a muffle furnace in synthesizing P2-Na0.67Ni0.33Mn0.67O2? Key to High-Performance Cathodes

- How is an industrial-grade ashing furnace utilized in 3D-printed bioactive glass? Master Debinding & Sintering

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- Why is a high-temperature muffle furnace typically selected for annealing? Achieve Optimal Ceramic Performance

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics