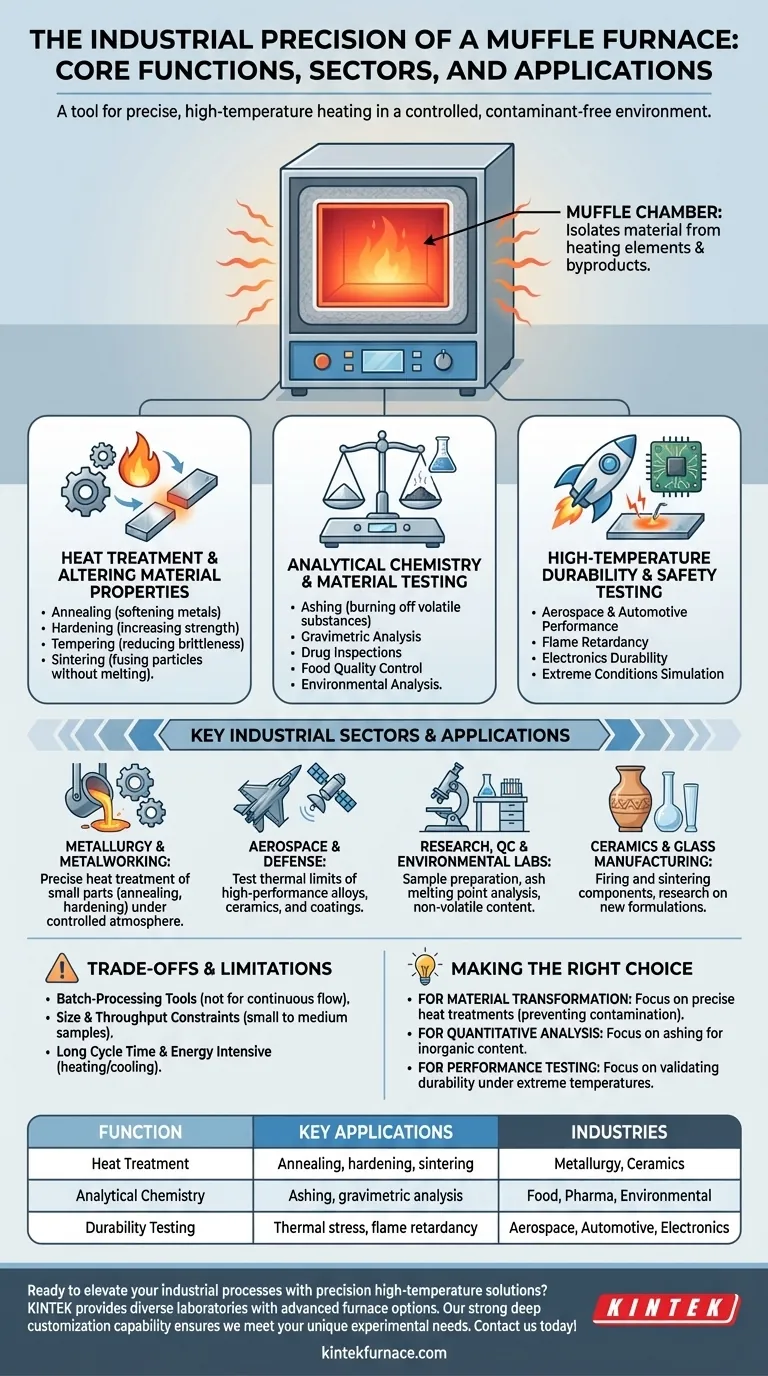

At its core, a muffle furnace is an indispensable tool for any industrial process requiring precise, high-temperature heating in a controlled, contaminant-free environment. Industries use them for three primary functions: altering the physical properties of materials through heat treatment, analyzing the chemical composition of a substance by burning away volatile components, and testing a material's durability under extreme thermal stress.

The true value of a muffle furnace lies in its design. By isolating the material inside a "muffle" or chamber, it separates the sample from the heating elements and any combustion byproducts, ensuring the process is defined purely by heat, not chemical reactions from the heat source itself.

The Core Functions: Why Industries Rely on Muffle Furnaces

A muffle furnace is not just a high-temperature oven; it's a precision instrument. Its applications are driven by its ability to deliver clean, uniform heat, enabling specific material transformations and analyses that would otherwise be impossible.

Heat Treatment and Altering Material Properties

Many applications use heat to fundamentally change a material's microstructure.

Processes like annealing (softening metals), hardening (increasing strength), and tempering (reducing brittleness) are critical in metallurgy. A muffle furnace provides the exact temperature cycles needed to achieve these desired properties in steel and other alloys.

In ceramics and powder metallurgy, sintering uses high heat to fuse particles together without melting them, creating solid, dense components.

Analytical Chemistry and Material Testing

Muffle furnaces are central to quality control and research labs for quantitative analysis.

The most common analytical use is ashing. This process involves heating a sample to burn off all organic and volatile substances, leaving behind only the non-combustible inorganic ash. This allows chemists to determine the exact percentage of inorganic filler or contaminants in a sample.

This is used for gravimetric analysis, drug inspections, quality control in the food industry, and analyzing soils, cements, and water quality samples.

High-Temperature Durability and Safety Testing

Industries must guarantee their products can withstand extreme conditions.

The aerospace and automotive industries use muffle furnaces to test the performance and flame retardancy of heat-resistant components, coatings, and composite materials.

Similarly, the electronics industry tests the durability of circuit boards and other components to ensure they can survive the high temperatures generated during operation.

Key Industrial Sectors and Their Specific Applications

While the functions are consistent, their application varies significantly across different sectors.

Metallurgy and Metalworking

This sector relies on muffle furnaces for the precise heat treatment of small steel parts and metals. The controlled atmosphere prevents oxidation and other unwanted surface reactions during annealing, hardening, and brazing.

Aerospace and Defense

For this industry, material failure is not an option. Muffle furnaces are used to test the thermal limits of high-performance alloys, ceramics, and coatings that must endure extreme operational temperatures.

Research, Quality Control, and Environmental Labs

These facilities use muffle furnaces for a wide range of analytical tasks. Applications include sample preparation for biomedical and pharmaceutical testing, ash melting point analysis in materials science, and determining the non-volatile content in samples for environmental compliance.

Ceramics and Glass Manufacturing

The production of advanced ceramics and specialized glass requires precise thermal processing. Muffle furnaces are used for firing and sintering components, ensuring uniform density and strength, as well as for conducting research on the properties of new glass formulations.

Understanding the Trade-offs and Limitations

While versatile, a muffle furnace is not the solution for every heating application. Understanding its limitations is key to using it effectively.

Batch Processing vs. Continuous Flow

Muffle furnaces are inherently batch-processing tools. They are ideal for treating individual components, running analytical tests on discrete samples, or handling small production runs. They are not suited for continuous, assembly-line-style manufacturing.

Size and Throughput Constraints

The insulated chamber that makes a muffle furnace so precise also limits its size. They are generally used for small to medium-sized parts and samples, not for large-scale industrial components.

Cycle Time and Energy Use

Heating to extreme temperatures and cooling down safely takes time. The long heating and cooling cycles can be an energy-intensive process, making it less efficient for applications that require rapid throughput.

Making the Right Choice for Your Goal

To apply this knowledge, align the furnace's capability with your primary objective.

- If your primary focus is material transformation: Use a muffle furnace for precise heat treatments like annealing, hardening, or sintering where preventing surface contamination is critical.

- If your primary focus is quantitative analysis: Employ the furnace for ashing to accurately determine the inorganic content of food, plastics, pharmaceuticals, or environmental samples.

- If your primary focus is performance testing: Leverage the furnace to subject components to extreme, controlled temperatures to validate their durability for aerospace, automotive, or electronics applications.

Ultimately, a muffle furnace is the tool of choice whenever your process demands high heat, absolute precision, and a chemically pure environment.

Summary Table:

| Function | Key Applications | Industries |

|---|---|---|

| Heat Treatment | Annealing, hardening, sintering | Metallurgy, Ceramics |

| Analytical Chemistry | Ashing, gravimetric analysis | Food, Pharma, Environmental |

| Durability Testing | Thermal stress, flame retardancy | Aerospace, Automotive, Electronics |

Ready to elevate your industrial processes with precision high-temperature solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs—whether for heat treatment, analysis, or testing. Contact us today to discuss how our tailored solutions can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency