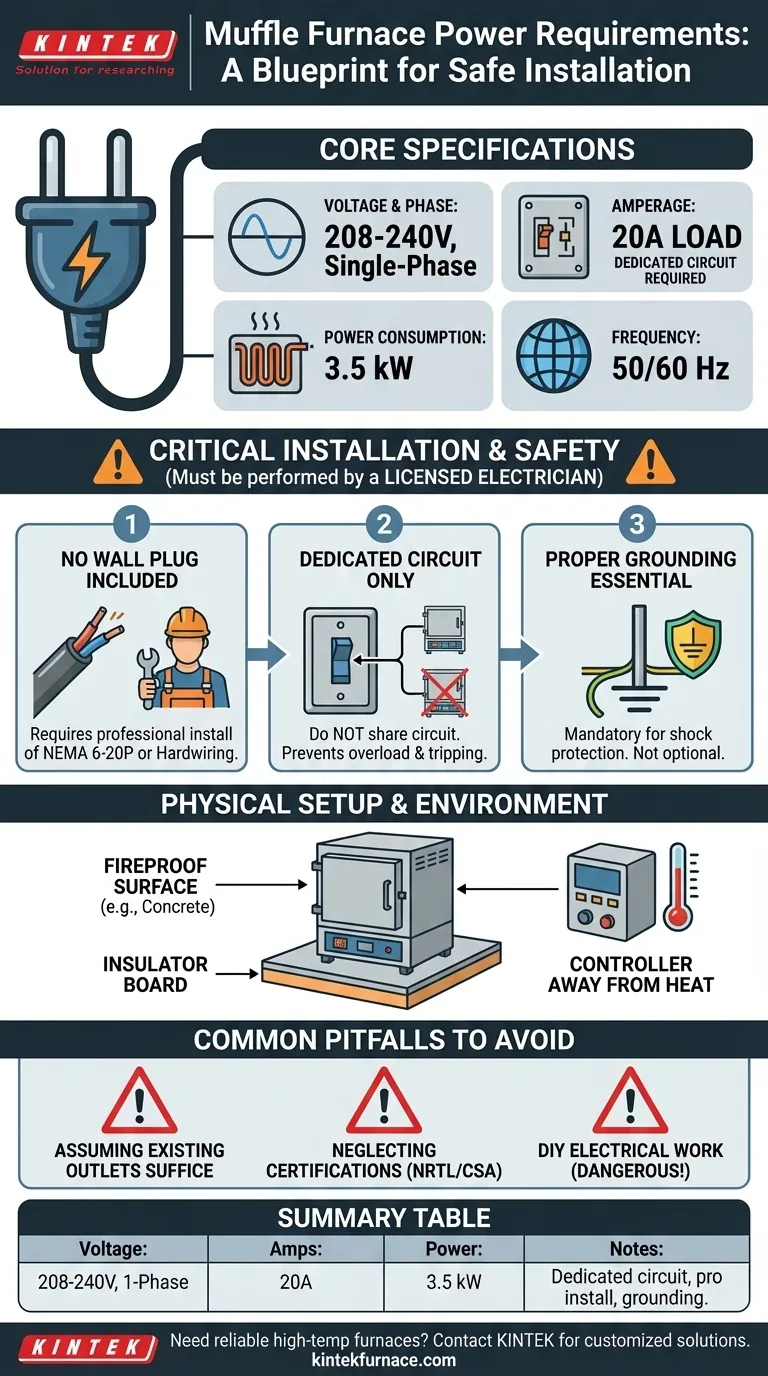

At a minimum, this muffle furnace requires a 208-240 Volt, single-phase power source capable of handling a 20 Amp load. The furnace's power consumption is rated at 3.5 kilowatts (kW), and it is designed to operate on a standard 50/60 Hz frequency. A critical detail is that the unit ships with a power cable but without a wall plug, which must be installed by a qualified professional.

The listed power specifications are more than just numbers; they are a blueprint for a safe and reliable installation. Understanding the relationship between voltage, amperage, and power is essential for ensuring your facility can support the equipment and prevent electrical hazards.

Deconstructing the Power Requirements

To properly prepare your lab or workshop, it's crucial to understand what each electrical specification means in practice.

Voltage, Phase, and Frequency

The 208-240V, single-phase requirement is typical for high-power equipment and is not compatible with a standard 120V wall outlet. This voltage is common in commercial facilities and residential settings for appliances like electric dryers or ovens. The 50/60 Hz rating means it is compatible with power grids in North America, Europe, and most other parts of the world.

Power Consumption (kW)

The 3.5 kW (3500 watts) rating represents the amount of power the furnace consumes to generate heat. This is the primary figure that determines the electrical load and the sustained demand on your circuit.

Current Draw (Amperage)

The references specify a 20A (Amp) requirement. This dictates the capacity of the circuit breaker and wiring needed. The furnace must be connected to a dedicated circuit rated for at least 20 Amps to prevent overloading and frequent tripping.

It is important to note a discrepancy in the provided data, with one reference mentioning 4.2A at 240V. This figure (approximately 1 kW) is significantly lower than the 3.5 kW rating and likely applies to a different, smaller model. You must verify the exact amperage for your specific model with the manufacturer.

Critical Installation and Safety Considerations

The electrical specifications directly inform the physical installation process, which has several non-negotiable safety requirements.

The Missing Plug

High-power equipment is often sold without a plug because global standards for high-voltage outlets vary (e.g., NEMA in North America vs. other standards abroad). This requires a licensed electrician to attach the correct plug for your region (such as a NEMA 6-20P) or to hardwire the unit directly into a junction box.

The Need for a Dedicated Circuit

A 3.5 kW furnace will draw a significant and sustained current. It must be the only device on its 20A circuit. Plugging other equipment into the same circuit creates a fire hazard and will almost certainly cause the breaker to trip during operation.

The Importance of Grounding

The references correctly state that proper grounding is essential. Grounding provides a safe path for electrical current in the event of a short circuit, protecting users from potentially lethal electric shock. This is not an optional step.

Physical and Environmental Setup

The furnace must be placed on a stable, fireproof surface like a concrete platform. Placing an asbestos board or similar insulator underneath is recommended to protect the countertop from extreme heat. The controller should be positioned away from the furnace body to prevent its electronic components from overheating.

Common Pitfalls to Avoid

Failing to properly plan for the installation can lead to costly delays, equipment damage, or serious safety incidents.

Assuming Existing Outlets are Sufficient

Never assume a vacant outlet can support this furnace. An electrician must verify that the outlet is wired to a dedicated 20A (or higher) breaker and uses the appropriate gauge wiring to handle the sustained load.

Neglecting Certifications

The furnace may be CE certified (for European markets), but NRTL or CSA certification (for North American safety standards) may be an additional option. Check with your institution's safety officer, as these certifications are often mandatory for use in a commercial or academic lab.

DIY Electrical Work

Given the high voltage and current involved, and the lack of a pre-installed plug, attempting to wire the furnace yourself without proper qualifications is extremely dangerous. Always hire a professional.

How to Prepare Your Facility

Use these guidelines to ensure your site is ready for the furnace.

- If you are planning a new installation: Instruct your electrician to install a dedicated 240V, 20A circuit with a NEMA 6-20R receptacle located near the furnace's final position.

- If you are retrofitting an existing space: Consult an electrician to perform a panel load calculation and confirm your building's electrical system can safely accommodate a new 20A, 240V circuit.

- Before finalizing your purchase: Always confirm the exact power (kW) and current (Amps) requirements for your specific furnace model directly with the manufacturer to resolve any discrepancies.

Properly planning for these electrical requirements is the most critical step toward the safe and efficient operation of your muffle furnace.

Summary Table:

| Specification | Details |

|---|---|

| Voltage | 208-240V, single-phase |

| Amperage | 20A |

| Power Consumption | 3.5 kW |

| Frequency | 50/60 Hz |

| Key Notes | Requires dedicated circuit, professional installation, and grounding for safety |

Need a reliable high-temperature furnace tailored to your lab's needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your laboratory's efficiency and safety!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing