Yes, a muffle furnace can be used for pyrolysis. Its fundamental design, which provides high, uniform heat within an isolated chamber, is well-suited for the thermal decomposition of organic materials. The furnace's ability to heat a substance without direct contact from a flame or heating elements is the key principle that makes this application possible.

Pyrolysis requires high temperatures in an oxygen-free environment to prevent combustion. A muffle furnace provides the necessary controlled, indirect heat, but achieving a truly oxygen-free atmosphere often requires specific modifications or operational procedures, such as purging the chamber with an inert gas.

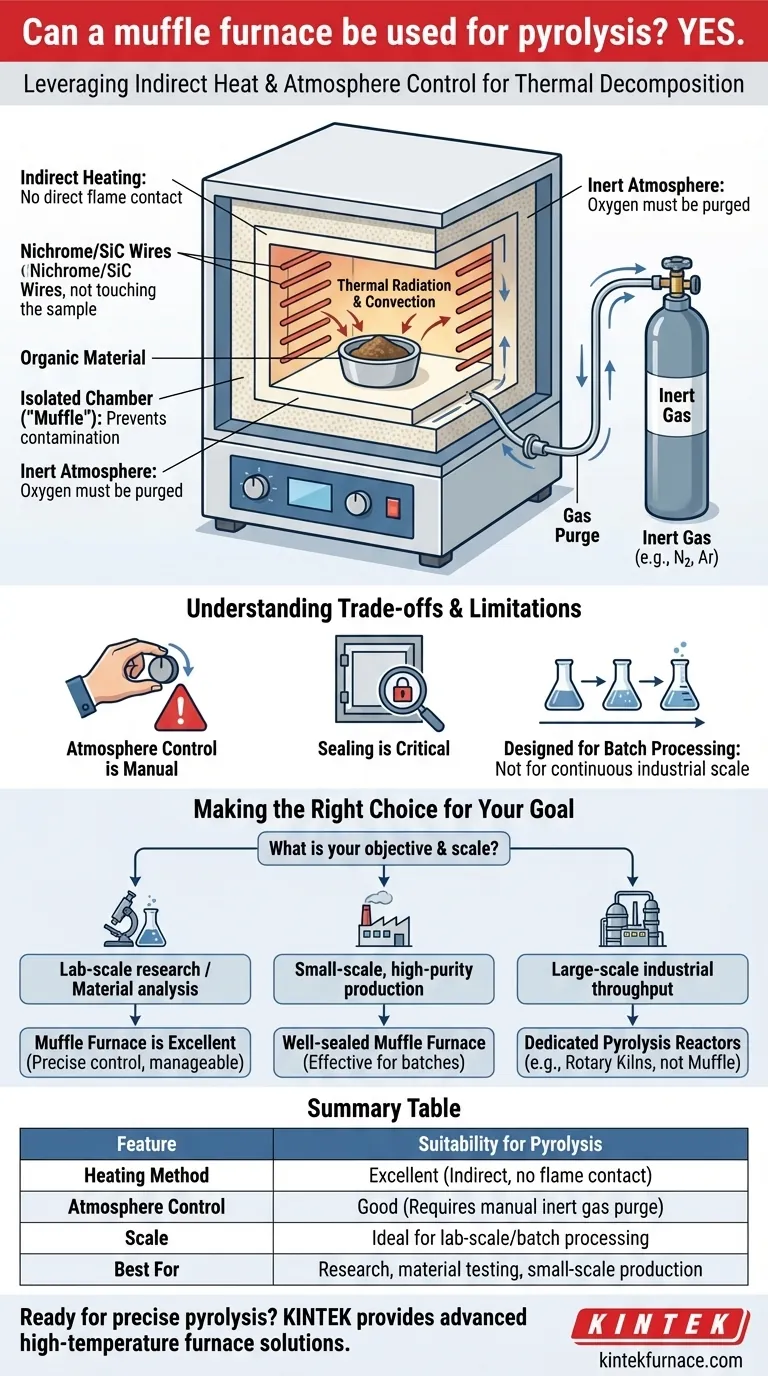

How a Muffle Furnace Enables Pyrolysis

A muffle furnace, also known as a chamber or box furnace, doesn't achieve pyrolysis by default, but its core features create the necessary conditions. The effectiveness of the process depends on understanding how these features work together.

The Principle of Indirect Heating

A muffle furnace operates by using electric heating elements, such as nichrome or silicon carbide wires, that line the walls of the heating chamber.

These elements generate intense heat, which is transferred to the sample inside through thermal radiation and convection.

Crucially, the sample never touches the heating elements or any open flame. This indirect heating is essential for pyrolysis, as direct flame contact would cause combustion, not thermal decomposition.

The Role of the "Muffle"

The term "muffle" refers to the insulated inner chamber, typically made of ceramic, that contains the sample.

This chamber isolates the material being heated from the heating elements and the external environment. This creates a clean, controlled space, preventing contamination from fuel byproducts or combustion gases that would be present in a fuel-fired furnace.

This isolation is what allows you to control the atmospheric conditions around the sample—a prerequisite for successful pyrolysis.

Achieving an Inert Atmosphere

Pyrolysis must occur in an oxygen-depleted (inert) atmosphere. A standard muffle furnace chamber contains air, which is rich in oxygen.

To perform true pyrolysis, this oxygen must be removed. The enclosed, sealed nature of a muffle furnace makes it possible to purge the chamber with an inert gas, such as nitrogen or argon.

This is typically done by introducing the gas through a port, allowing it to displace the oxygen before and during the heating cycle.

Understanding the Trade-offs and Limitations

While a muffle furnace is a capable tool for pyrolysis, it is not a dedicated pyrolysis reactor. You must be aware of its limitations to ensure accurate and safe results.

Atmosphere Control is Manual

A muffle furnace does not automatically create an inert atmosphere. You are responsible for designing and implementing a safe and effective gas purging system.

Without this crucial step, heating an organic sample will result in ashing or combustion, not pyrolysis.

Sealing is Critical

The effectiveness of an inert gas purge depends entirely on the quality of the furnace's door seal.

Any leaks will allow oxygen to seep back into the chamber, especially at high temperatures, compromising the integrity of the process. For rigorous applications, furnaces with specialized gaskets and clamping mechanisms are superior.

Designed for Batch Processing

Muffle furnaces are designed for batch processing: a sample is loaded, heated, cooled, and then removed.

This makes them ideal for laboratory research, material testing, and small-scale production. However, they are not efficient for large-scale, continuous industrial pyrolysis, where dedicated reactors like rotary kilns are used.

Making the Right Choice for Your Goal

Whether a muffle furnace is the right tool depends entirely on your objective and scale.

- If your primary focus is lab-scale research or material analysis: A muffle furnace is an excellent and widely used tool, offering precise temperature control in a manageable, controlled environment.

- If your primary focus is small-scale, high-purity production: A well-sealed muffle furnace with a reliable inert gas system can be a very effective solution for producing char, bio-oil, or other pyrolytic products in batches.

- If your primary focus is large-scale industrial throughput: A muffle furnace is not the right choice; you should investigate dedicated, continuous-flow pyrolysis reactors designed for industrial efficiency.

By leveraging its principles of indirect heat and atmospheric isolation, you can adapt a muffle furnace into a powerful and precise tool for your pyrolysis objectives.

Summary Table:

| Feature | Suitability for Pyrolysis |

|---|---|

| Heating Method | Excellent (Indirect, no flame contact) |

| Atmosphere Control | Good (Requires manual inert gas purge) |

| Scale | Ideal for lab-scale/batch processing |

| Best For | Research, material testing, small-scale production |

Ready to achieve precise, controlled pyrolysis in your lab?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our Muffle Furnaces are engineered for superior thermal uniformity and can be customized with integrated gas purging systems to meet your exact pyrolysis requirements.

Let us help you build the perfect solution for your research or production needs. Contact our experts today for a consultation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production