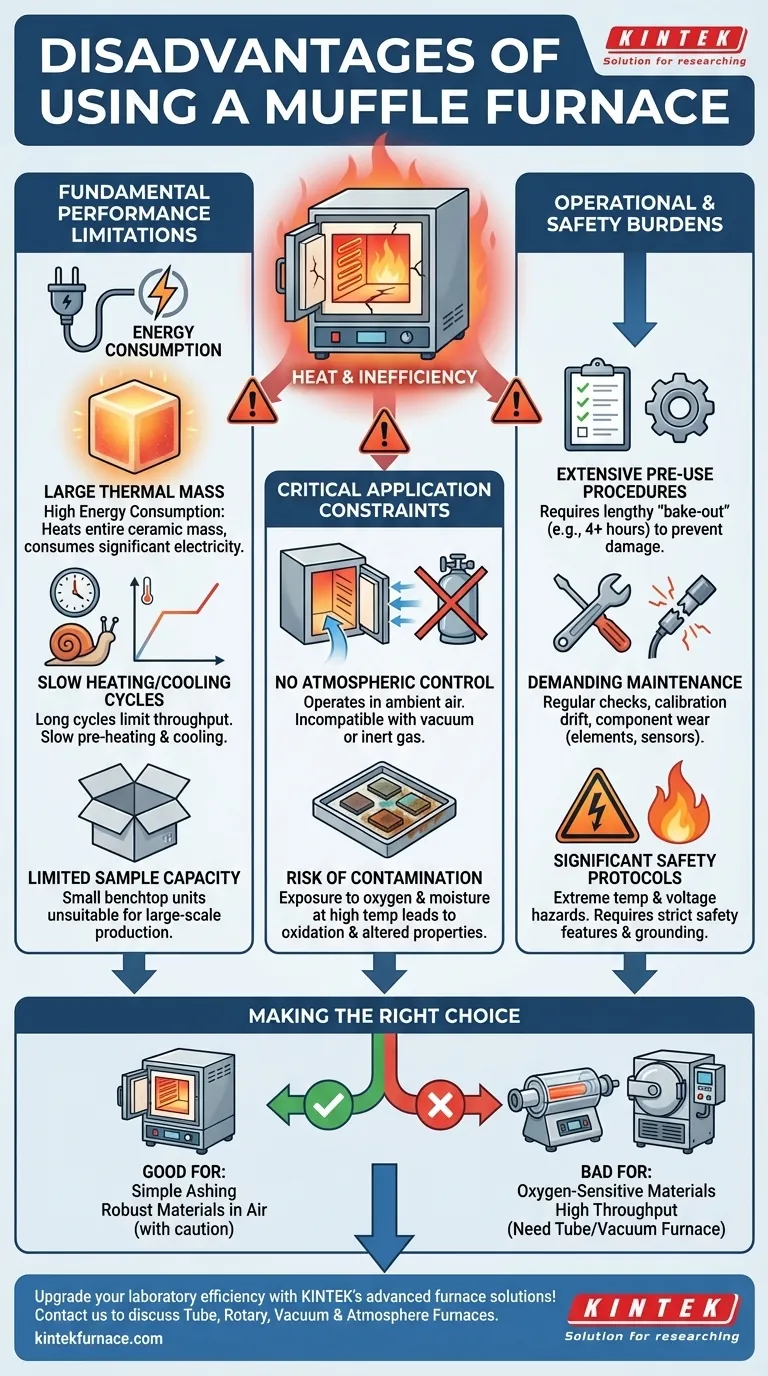

At its core, the disadvantages of a muffle furnace stem from its design as a simple, high-temperature chamber. The primary drawbacks include high energy consumption, inherent inefficiency, and a lack of atmospheric control, which makes it unsuitable for many sensitive applications. Furthermore, its operation demands strict safety protocols and regular maintenance.

While effective for basic high-temperature tasks in ambient air, a muffle furnace's limitations in efficiency, atmospheric control, and operational speed make it a poor choice for processes requiring precision, high throughput, or a non-reactive environment.

Fundamental Performance Limitations

A muffle furnace's design prioritizes reaching high temperatures over speed or efficiency. This leads to several key performance drawbacks that must be considered.

High Energy Consumption

The furnace operates by heating electric elements that radiate heat into a ceramic chamber, or "muffle." This entire ceramic mass must be brought to temperature, a process that consumes a significant amount of electrical energy, especially during startup and for long-duration runs.

Slow Heating and Cooling Cycles

Because the furnace relies on heating a large thermal mass (the muffle), it cannot change temperatures quickly. The initial pre-heating and mandatory drying procedures can take hours, and cooling down is equally slow, limiting sample throughput.

Limited Sample Capacity

Most muffle furnaces are benchtop units designed for lab-scale work or small parts. Their internal capacity is often restricted, making them entirely unsuitable for any form of large-scale or high-volume production.

Critical Application Constraints

The most significant disadvantage is the furnace's inability to control its internal atmosphere. This single factor disqualifies it from a wide range of modern materials processing applications.

Incompatibility with Vacuum or Controlled Atmospheres

A muffle furnace is not sealed and operates in ambient air. It cannot hold a vacuum or be filled with an inert gas like argon or nitrogen. This makes it useless for applications where oxygen would damage the sample, such as sintering sensitive ceramics or heat-treating reactive metals. For these, a vacuum furnace or tube furnace is required.

Risk of Sample Contamination

Because the chamber is open to air, samples are directly exposed to oxygen, nitrogen, and moisture at high temperatures. This can lead to unwanted oxidation and contamination, altering the chemical or physical properties of the material you are trying to process.

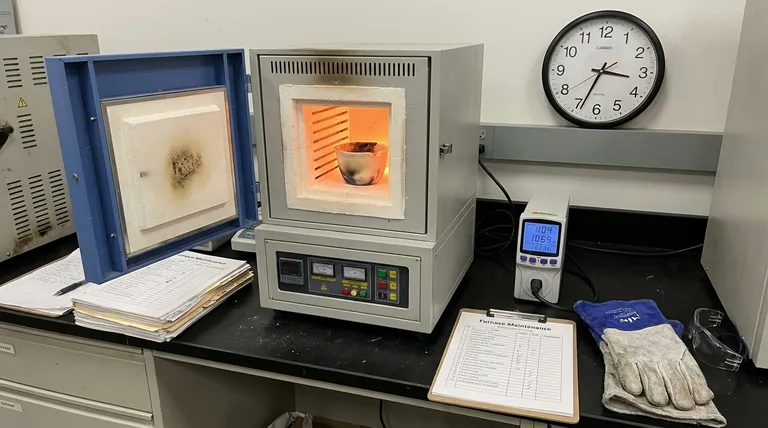

Understanding the Operational and Safety Burdens

Beyond performance, owning and operating a muffle furnace carries a significant burden of responsibility. It is not a simple "plug-and-play" appliance.

Extensive Pre-Use Procedures

A new furnace or one that has been idle requires a lengthy "drying" or "bake-out" procedure. This involves slowly heating the furnace for several hours (e.g., four hours from 200°C to 600°C) to drive out moisture from the ceramic insulation, preventing damage.

Demanding Maintenance Requirements

Optimal performance requires regular checks and potential calibration. Key components like heating elements, thermocouples (temperature sensors), and control relays are subject to wear and failure. Functions like calibration offset exist because temperature accuracy can drift over time.

Significant Safety Protocols

Muffle furnaces operate at extreme temperatures and high voltages, posing serious fire and electrical hazards. Safe operation is non-negotiable and requires features like overheat prevention, earth leakage breakers, and proper grounding to a dedicated electrical circuit. Failure to adhere to these protocols can have catastrophic consequences.

Making the Right Choice for Your Goal

To determine if a muffle furnace is the correct tool, you must weigh its simplicity against its considerable limitations.

- If your primary focus is simple ashing or heat-treating robust materials in air: A muffle furnace is a cost-effective and suitable tool, provided you follow all safety and operational procedures.

- If your primary focus is processing oxygen-sensitive materials, polymers, or advanced ceramics: A muffle furnace is the wrong tool; you need a tube furnace or vacuum furnace for atmospheric control.

- If your primary focus is high throughput or rapid temperature changes: The slow thermal cycling of a muffle furnace makes it highly inefficient for your goal.

Understanding these inherent disadvantages ensures you select the right instrument for your specific application, preventing costly errors and unsafe operation.

Summary Table:

| Disadvantage | Impact |

|---|---|

| High energy consumption | Increases operational costs and environmental footprint |

| Slow heating and cooling cycles | Reduces throughput and efficiency |

| Limited sample capacity | Not suitable for large-scale production |

| No atmospheric control | Causes sample contamination and oxidation |

| High maintenance and safety needs | Requires strict protocols and regular upkeep |

Upgrade your laboratory efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your processes and overcome muffle furnace limitations!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency