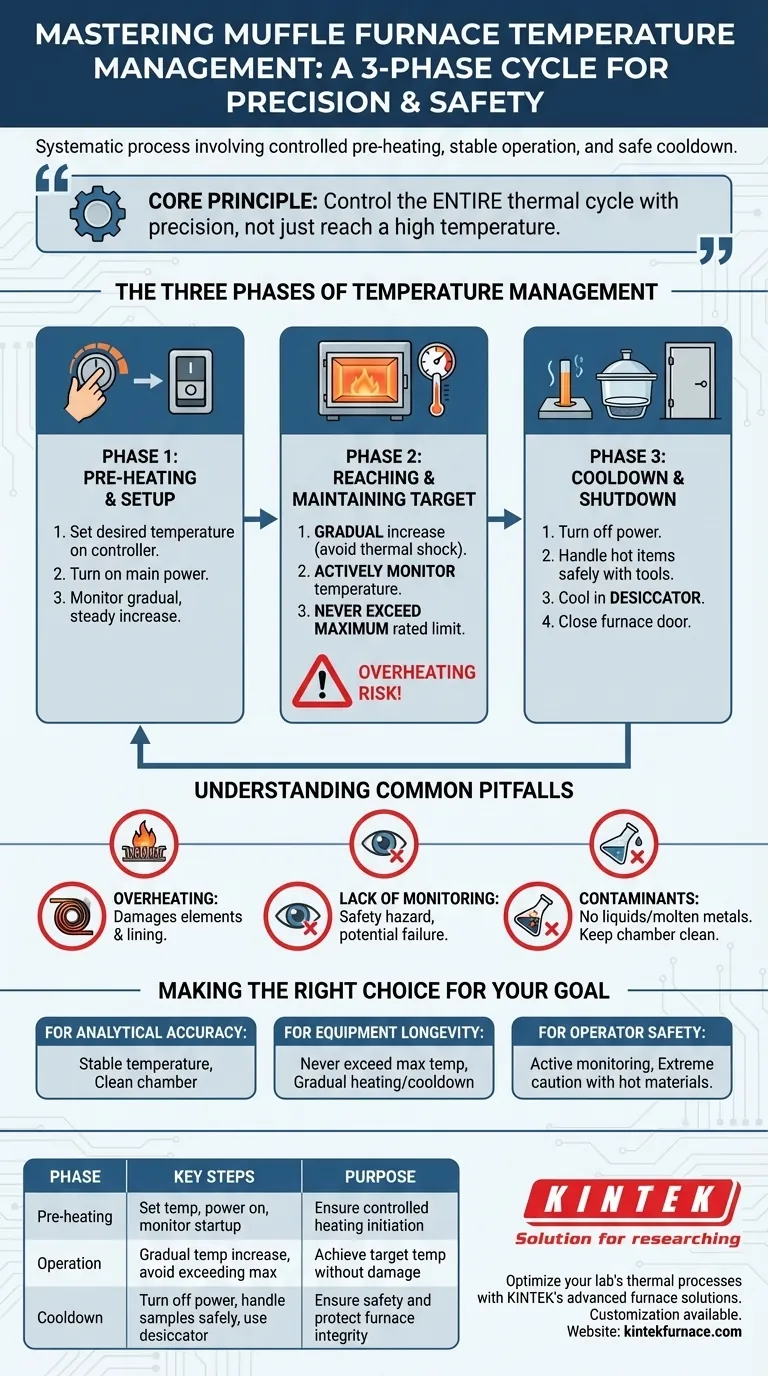

Properly managing a muffle furnace's temperature is a systematic process involving three distinct phases: controlled pre-heating, stable operation, and a safe cooldown sequence. You must set the desired temperature on the controller, allow the furnace to heat up gradually, and actively monitor it to ensure it does not exceed its maximum rated limit. After the process is complete, power must be cut, and the furnace should be allowed to cool properly before handling materials.

The core principle of muffle furnace operation is not just reaching a high temperature, but controlling the entire thermal cycle with precision. This discipline is essential for ensuring accurate experimental results, protecting the equipment from damage, and guaranteeing operator safety.

The Three Phases of Temperature Management

Operating a muffle furnace correctly involves more than simply turning it on and off. Each phase of the thermal cycle has specific steps and considerations.

Phase 1: Pre-heating and Setup

Before you begin, the furnace must be set up correctly. This ensures the heating process starts controllably.

First, adjust the temperature controller to your required working temperature. Once set, you can turn on the main power or start code for the furnace.

Confirm that the furnace is operating normally. A successful start is indicated by a reading on the ammeter and a steady, gradual increase shown on the temperature control meter.

Phase 2: Reaching and Maintaining Target Temperature

This phase is where precision and monitoring are most critical. The goal is to reach your target temperature without stressing the equipment.

The temperature should be raised gradually. This is often achieved by slowly increasing the voltage, which prevents thermal shock to the heating elements and the furnace chamber.

The most important rule is to never exceed the furnace's maximum rated temperature. Doing so can cause irreversible damage to the heating elements and the internal furnace lining.

Phase 3: Cooldown and Shutdown

The shutdown procedure is just as important as the heating process for maintaining the furnace's longevity and ensuring safety.

Once your experiment is complete, turn off the power to the furnace. Carefully withdraw your sample from the heating chamber, taking precautions against the extreme heat.

Heated items, especially crucibles, must be handled with appropriate tools and allowed to cool completely to prevent burns. They should be transferred to a desiccator for controlled, moisture-free cooling.

Finally, close the furnace door after use. This protects the sensitive furnace chamber from ambient air moisture, which can cause corrosion and degradation over time.

Understanding the Common Pitfalls

Even with automatic controllers, a muffle furnace is not a "set it and forget it" device. Awareness of potential failures is key to safe operation.

The Risk of Overheating

The single most common cause of furnace damage is overheating. Exceeding the rated temperature, even for a short time, can burn out the furnace's heating wire or permanently damage the insulating lining.

The Need for Active Monitoring

You must monitor the furnace throughout its operation. Automatic temperature controls can fail, and without supervision, the furnace could overheat and create a significant safety hazard. Constant vigilance prevents accidents.

Maintaining Chamber Integrity

The internal chamber is the core of the furnace. To protect it, never pour any liquids or molten metals directly into the furnace. Always keep the chamber clean and free of residue, as contaminants can damage the lining at high temperatures.

Making the Right Choice for Your Goal

Your primary objective will determine which aspect of temperature management you should prioritize.

- If your primary focus is analytical accuracy: Strict adherence to a stable, consistent target temperature and maintaining a perfectly clean chamber are your most critical tasks.

- If your primary focus is equipment longevity: Never exceeding the maximum temperature and following a gradual heating and proper cooldown procedure are essential to protect your investment.

- If your primary focus is operator safety: Active monitoring during operation and using extreme caution when handling hot materials are the non-negotiable rules.

Mastering the thermal cycle of your muffle furnace transforms it from a simple heater into a precise scientific instrument.

Summary Table:

| Phase | Key Steps | Purpose |

|---|---|---|

| Pre-heating | Set temperature, turn on power, monitor startup | Ensure controlled heating initiation |

| Operation | Gradual temperature increase, avoid exceeding max limit | Achieve target temperature without damage |

| Cooldown | Turn off power, handle samples safely, use desiccator | Ensure safety and protect furnace integrity |

Optimize your lab's thermal processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, enhancing accuracy, safety, and longevity. Contact us today to discuss how we can elevate your research and operations!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency