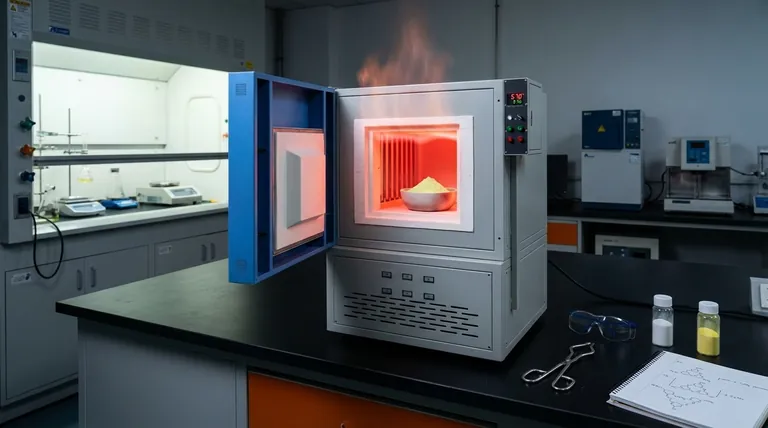

A high-temperature muffle furnace functions as the critical reaction vessel for converting organic precursors into graphitic carbon nitride (g-C3N4). It facilitates a process known as thermal polycondensation, typically conducted around 570 °C in an air atmosphere. This controlled heating drives the chemical transformation and deamination required to build the material's stable heptazine structure.

Core Takeaway The muffle furnace provides more than just heat; it ensures the thermal field uniformity and temperature precision necessary to polymerize simple precursors like urea into a highly crystalline semiconductor. This structural integrity is the primary determinant of the material's final photocatalytic performance.

The Mechanism: Thermal Polycondensation

Driving Chemical Transformation

The primary role of the furnace is to execute the thermal polycondensation of precursors, such as urea.

Deamination and Condensation

Through sustained heating, the furnace enables deamination-condensation. This process removes amine groups and facilitates the linkage of molecules to form the backbone of the material.

Formation of Heptazine Structures

The ultimate goal of this thermal treatment is the creation of a stable heptazine (tri-s-triazine) structure. This specific arrangement of atoms is fundamental to the stability and electronic properties of g-C3N4.

Critical Process Controls

Precise Temperature Maintenance

The furnace must maintain a stable environment, typically around 570 °C (or 550 °C depending on specific protocols).

Thermal Field Uniformity

Uniform distribution of heat within the chamber is non-negotiable. Variations in the thermal field lead to uneven polymerization, resulting in defects that hamper performance.

Controlled Heating Rates

Precision furnaces allow for specific heating rates, such as 2 °C per minute. Gradual heating ensures the reaction proceeds completely without thermal shock or incomplete polymerization.

The Impact on Material Quality

Determining Crystallinity

The precision of the furnace directly dictates the crystallinity of the resulting g-C3N4 nanopowders. Higher crystallinity generally correlates with better charge transport and stability.

Defining Photocatalytic Activity

The base photocatalytic activity is established during this heating phase. If the furnace fails to maintain the correct parameters, the material will lack the periodic structure required to effectively absorb light and drive reactions.

Understanding the Trade-offs

Temperature Sensitivity

Operating the furnace below the optimal range results in incomplete polymerization, leaving behind unreacted precursors.

Overheating Risks

Conversely, exceeding the optimal temperature window can lead to the decomposition of the g-C3N4 structure itself, destroying the active sites necessary for photocatalysis.

Atmosphere Dependence

While many syntheses occur in air, the furnace's ability to maintain this atmosphere consistently is vital. Fluctuations in airflow or atmospheric composition can alter the oxidation states and defect density of the final product.

Making the Right Choice for Your Goal

When configuring a muffle furnace for g-C3N4 synthesis, consider your specific research objectives:

- If your primary focus is basic substrate synthesis: Prioritize a furnace with exceptional thermal uniformity at 570 °C to ensure high crystallinity and a stable heptazine structure.

- If your primary focus is minimizing defects: Utilize a programmable furnace to enforce slow, controlled heating rates (e.g., 2 °C/min) to guarantee complete polycondensation.

- If your primary focus is composite formation (e.g., g-C3N4/TiO2): Ensure the furnace can hold lower annealing temperatures (such as 350 °C) precisely to facilitate interface bonding without degrading the individual components.

The quality of your photocatalyst is only as good as the thermal precision used to create it.

Summary Table:

| Process Parameter | Role in g-C3N4 Synthesis | Impact on Material |

|---|---|---|

| Temperature (570°C) | Facilitates thermal polycondensation | Forms stable heptazine structure |

| Uniform Thermal Field | Ensures consistent polymerization | High crystallinity & charge transport |

| Heating Rate (2°C/min) | Enables gradual deamination | Minimizes structural defects |

| Atmosphere Control | Maintains air/gas stability | Controls oxidation and defect density |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect heptazine structure for g-C3N4 photocatalysts requires absolute thermal precision. At KINTEK, we specialize in providing high-performance Muffle, Tube, and Vacuum furnaces designed to meet the rigorous demands of advanced lab research.

Why choose KINTEK?

- Expert R&D: Our systems are engineered for superior thermal uniformity and precise ramp-rate control.

- Customizable Solutions: Whether you are working on g-C3N4 nanopowders or complex CVD systems, we tailor our equipment to your unique synthesis protocols.

- Scalable Performance: Reliable results from basic substrate synthesis to advanced composite formation.

Ready to enhance your lab's efficiency and material quality? Contact us today to discuss your custom furnace needs!

References

- Hong Tu, Jian Wu. Unveiling the Impact of Microstructure Alterations on Photocatalytic Hydrogen Peroxide Preparation via <scp>DFT</scp> Prediction and Analysis. DOI: 10.1002/eem2.70016

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the primary technical function of an industrial muffle furnace? Achieve Pure Hematite via Precision Oxidation

- What are the advantages of using a Microwave Muffle Furnace? Faster, Higher-Quality Activated Carbon Preparation

- What are the main applications of a box muffle furnace in material research? Unlock Precision Heat Treatment and Analysis

- What is the function of a high-temperature box resistance furnace? Optimize Hierarchical Zeolite Synthesis

- How does a muffle furnace facilitate the final conversion of ZnO nanopowders? Precision Calcination for Pure Results

- What are the temperature capabilities of muffle furnaces? Find Your Perfect High-Temp Solution

- How does a box muffle furnace work? Achieve Clean, Controlled Heating for Your Lab

- What are the key high-temperature applications of a digital muffle furnace? Unlock Precision in Materials Processing