A Microwave Muffle Furnace fundamentally changes the preparation of activated carbon by utilizing volumetric heating rather than traditional thermal conduction. This method uses microwave radiation to penetrate precursor particles instantly, generating heat from within to significantly accelerate processing times. The result is not just a faster process, but a superior material characterized by higher microporosity, a larger specific surface area, and enhanced adsorption capacity.

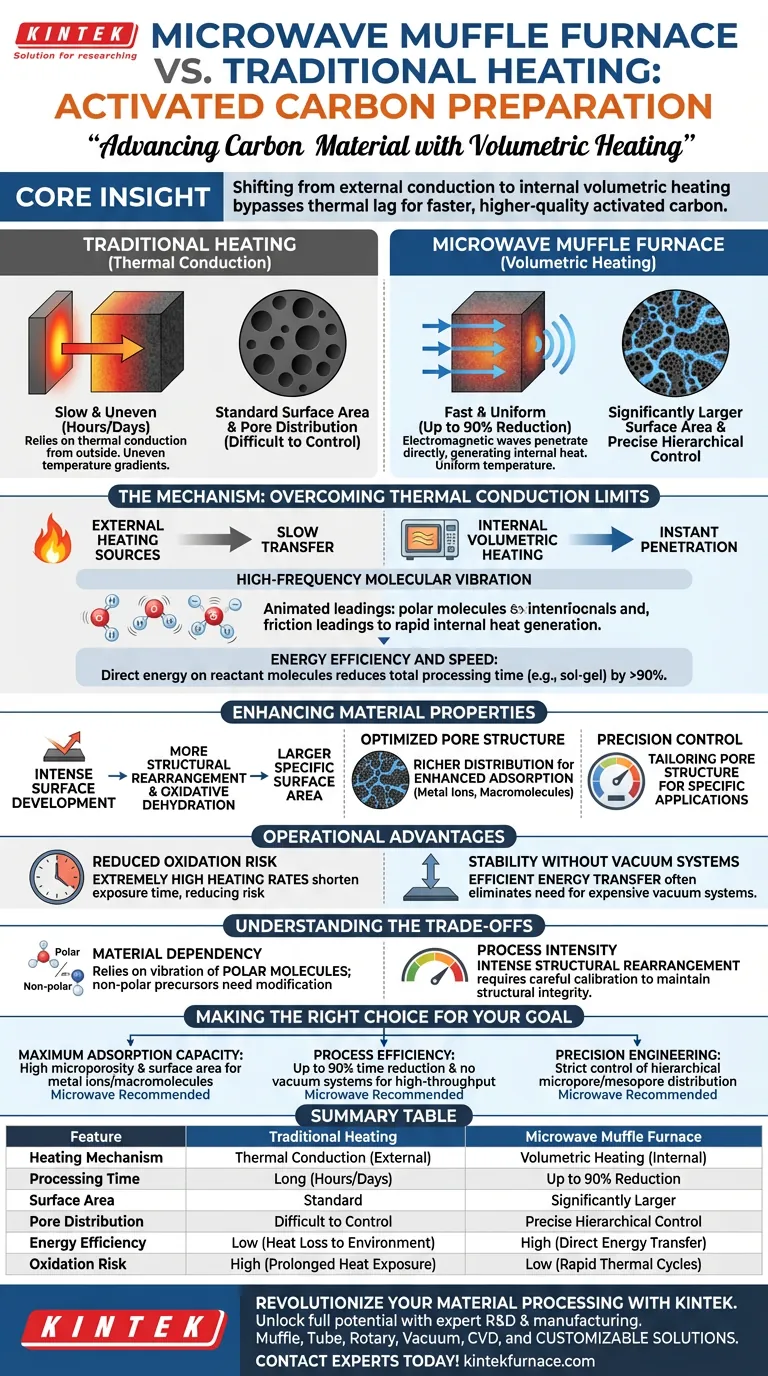

The Core Insight By shifting from external heating sources to internal volumetric heating, microwave muffle furnaces bypass the thermal lag of traditional methods. This allows for intense, uniform surface development that produces higher-quality activated carbon capable of superior performance in adsorbing metal ions and macromolecules.

The Mechanism of Volumetric Heating

Overcoming Thermal Conduction Limits

Traditional heating methods rely on thermal conduction, where heat slowly transfers from the outside of the material to the core. This often results in uneven temperature gradients.

Microwave Muffle Furnaces utilize electromagnetic waves to penetrate directly into the deep layers of precursor particles. This generates heat throughout the entire volume of the material simultaneously.

High-Frequency Molecular Vibration

The system works by inducing high-frequency vibrations in polar molecules within the material.

This friction generates internal heat rapidly, leading to superior temperature uniformity compared to conventional external heating sources.

Energy Efficiency and Speed

Because the energy acts directly on the reactant molecules, energy transfer is highly efficient.

This mechanism drastically reduces experimental cycles. In processes like sol-gel procedures, total processing time (including polymerization and drying) can be reduced by more than 90 percent.

Enhancing Material Properties

Intense Surface Development

The rapid internal heating promotes more intense structural rearrangement and oxidative dehydration than chemical activation alone.

This leads to the formation of a significantly larger specific surface area, which is the primary indicator of activated carbon quality.

Optimized Pore Structure

Microwave-assisted activation fosters a richer distribution of both micropores and mesopores.

This hierarchical pore structure is critical for performance, specifically enhancing the material's capacity to adsorb complex targets like metal ions and macromolecules.

Precision Control

The nature of microwave heating allows for precise control over the pore structure of carbon gels.

Researchers can fine-tune the process to achieve specific distributions of micropores and mesopores, tailoring the carbon for exact application needs.

Operational Advantages

Reduced Oxidation Risk

Traditional high-temperature methods often expose materials to prolonged heat, increasing the risk of unwanted oxidation.

The extremely high heating rates of a microwave reactor shorten the exposure time, significantly reducing the risk of material oxidation.

Stability Without Vacuum Systems

The efficient energy transfer allows for stable characterization of emissivity changes during rapid thermal cycles.

This often eliminates the need for expensive vacuum systems typically required to protect materials during conventional heating.

Understanding the Trade-offs

Material Dependency

Microwave heating relies on the vibration of polar molecules.

The efficiency of this process is strictly dependent on the material's dielectric properties. Precursors that lack polar characteristics may not respond as effectively to volumetric heating without chemical modification or impregnation.

Process Intensity

The "intense structural rearrangement" that creates superior pores is a powerful force.

While this leads to better adsorption, it requires careful calibration. The rapid heating rates must be managed to ensure the structural integrity of the carbon skeleton is maintained while pores are being developed.

Making the Right Choice for Your Goal

To determine if a Microwave Muffle Furnace is the right investment for your application, consider your specific targets:

- If your primary focus is Maximum Adsorption Capacity: This method is superior for creating the high microporosity and large surface area needed to adsorb metal ions and macromolecules.

- If your primary focus is Process Efficiency: The ability to reduce processing times by up to 90% and eliminate vacuum systems makes this the optimal choice for high-throughput operations.

- If your primary focus is Precision Engineering: Choose this method if you need to strictly control the hierarchical distribution of micropores and mesopores for specialized filtering applications.

Microwave heating transforms activated carbon preparation from a slow thermal process into a rapid, precise structural engineering capability.

Summary Table:

| Feature | Traditional Heating | Microwave Muffle Furnace |

|---|---|---|

| Heating Mechanism | Thermal Conduction (External) | Volumetric Heating (Internal) |

| Processing Time | Long (Hours/Days) | Up to 90% Reduction |

| Surface Area | Standard | Significantly Larger |

| Pore Distribution | Difficult to Control | Precise Hierarchical Control |

| Energy Efficiency | Low (Heat Loss to Environment) | High (Direct Energy Transfer) |

| Oxidation Risk | High (Prolonged Heat Exposure) | Low (Rapid Thermal Cycles) |

Revolutionize Your Material Processing with KINTEK

Unlock the full potential of your carbon research with precision heating technology. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-performance laboratory equipment, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard configurations or a customizable solution tailored to your unique experimental needs, we provide the tools to ensure superior material properties and unmatched process efficiency.

Ready to upgrade your laboratory’s capabilities? Contact our experts today to find your perfect furnace solution!

Visual Guide

References

- Sylwia Kukowska, Katarzyna Szewczuk‐Karpisz. New fruit waste-derived activated carbons of high adsorption performance towards metal, metalloid, and polymer species in multicomponent systems. DOI: 10.1038/s41598-025-85409-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the industrial uses of a muffle furnace? Enhance Precision and Purity in High-Temp Applications

- What precautions should be taken with the thermostat before an experiment? Ensure Accuracy and Safety in Your Lab

- What training is required for operators of a muffle furnace? Essential Skills for Safe and Efficient Operation

- How do Box high-temperature furnaces and thermocouples ensure HP40Nb alloy test precision? Master Thermal Stability

- What critical role does a high-temperature sintering furnace play in the treatment of Zinc Oxide pellets? Expert Insights

- Why is a laboratory muffle furnace used to bake experimental apparatus? Ensure Purity in Shale Oil & Gas Simulations

- Why is a low-temperature annealing furnace necessary for coal tar film sensor production? Achieve Precise Stabilization

- Why use a high-temp box resistance furnace for Ca2.5Ag0.3Sm0.2Co4O9 sintering? Ensure Phase Purity and Alignment