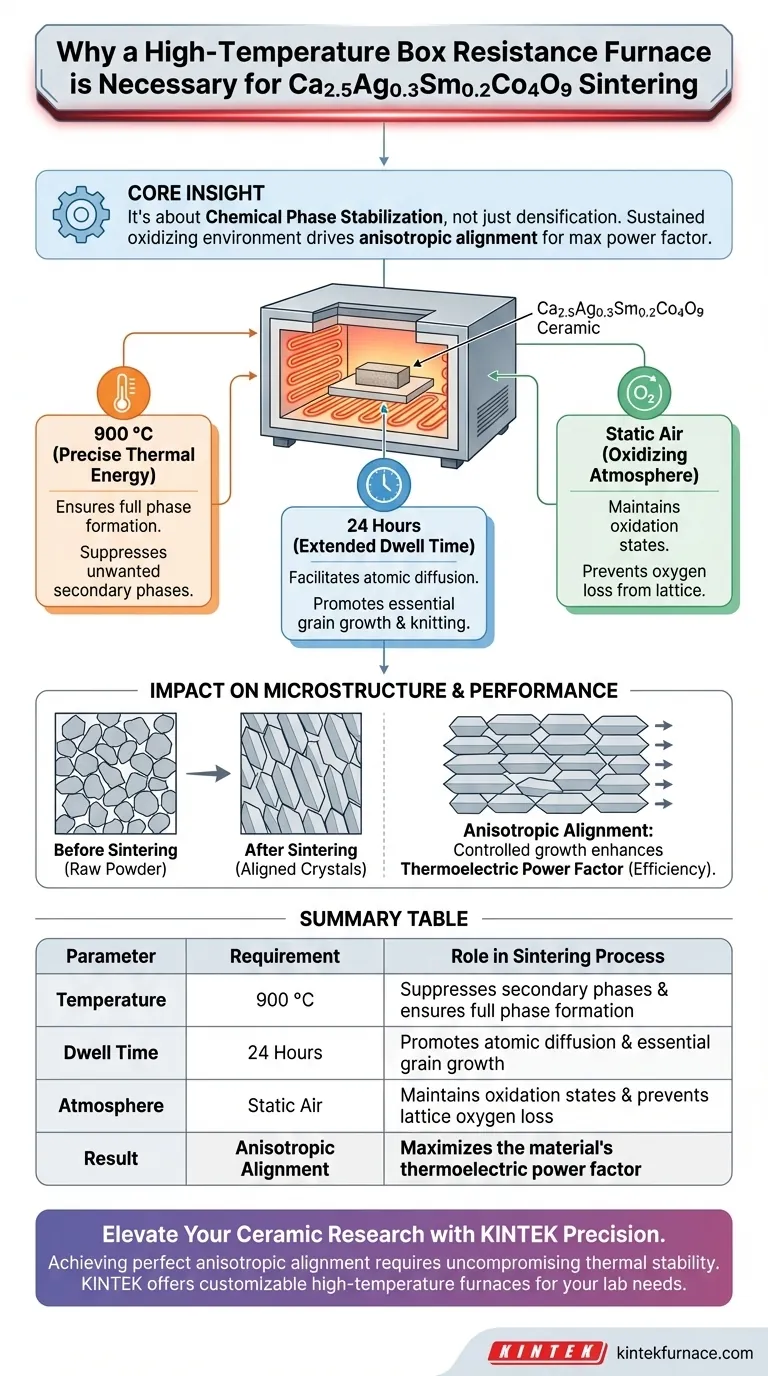

A high-temperature box resistance furnace is indispensable for processing Ca2.5Ag0.3Sm0.2Co4O9 ceramics because it provides the precise thermal stability and atmospheric conditions required to stabilize its complex crystal structure. specifically, this equipment enables a long-term heat treatment (typically 24 hours) at 900 °C in static air, which is the exact threshold needed to suppress secondary phases and promote essential grain growth.

Core Insight: Sintering this specific ceramic is not merely about densification; it is about chemical phase stabilization. The furnace provides a sustained oxidizing environment that drives the anisotropic crystal alignment necessary to maximize the material's thermoelectric power factor.

The Role of Thermal Stability in Phase Formation

Achieving Phase Purity

The synthesis of Ca2.5Ag0.3Sm0.2Co4O9 involves a complex solid-state reaction. A standard rapid-fire process is insufficient to integrate the Silver (Ag) and Samarium (Sm) dopants into the lattice structure.

The box resistance furnace maintains a strict temperature of 900 °C. This specific thermal energy is required to ensure full phase formation and effectively suppress the creation of unwanted secondary phases that would degrade performance.

Promoting Grain Growth

Time is as critical as temperature in this process. The furnace allows for a prolonged dwell time, often extending to 24 hours.

This extended duration facilitates atomic diffusion. It allows the microscopic grains within the ceramic to grow and knit together, reducing the boundaries that scatter electrons and hinder performance.

Impact on Microstructure and Performance

Inducing Anisotropic Alignment

For thermoelectric materials like Ca-Co-O ceramics, the direction of the crystals matters. The properties are anisotropic, meaning they perform better in one direction than another.

The controlled environment of the box furnace encourages the crystals to align in a specific orientation during growth. This alignment significantly enhances the thermoelectric power factor, which is the primary measure of the material's efficiency.

The Importance of Static Air

Unlike vacuum furnaces or reducing atmospheres, a box resistance furnace typically operates with static air.

This oxygen-rich environment is vital for oxide ceramics. It ensures the cobalt and other metal ions remain in their proper oxidation states, preventing the material from degrading or losing oxygen from its lattice structure.

Understanding the Trade-offs

Process Duration vs. Efficiency

The necessity of a 24-hour heat treatment cycle creates a bottleneck in manufacturing throughput. While essential for high quality, this long dwell time increases energy consumption and limits the speed of production.

Atmosphere Limitations

While static air is ideal for this specific composition, a standard box furnace lacks the ability to actively purge byproducts if the raw materials contain significant organic binders.

If the "green body" (un-sintered ceramic) contains high levels of binders, the static air might become saturated with off-gassing polymers. This could potentially interfere with the purity of the final oxide phase if not managed with a preliminary burnout stage.

Making the Right Choice for Your Goal

To get the most out of your Ca2.5Ag0.3Sm0.2Co4O9 sintering process, align your furnace parameters with your specific performance targets:

- If your primary focus is maximizing thermoelectric output: Ensure the furnace maintains a strict 24-hour dwell time at 900 °C to guarantee optimal anisotropic alignment.

- If your primary focus is phase purity: Verify that the furnace vent is set to maintain a static air environment, preventing the reduction of metal oxides that can occur in vacuum or inert atmospheres.

The high-temperature box resistance furnace is the bridge that transforms a raw powder mixture into a functionally aligned, high-performance energy material.

Summary Table:

| Parameter | Requirement | Role in Sintering Process |

|---|---|---|

| Temperature | 900 °C | Suppresses secondary phases & ensures full phase formation |

| Dwell Time | 24 Hours | Promotes atomic diffusion and essential grain growth |

| Atmosphere | Static Air | Maintains oxidation states and prevents lattice oxygen loss |

| Result | Anisotropic Alignment | Maximizes the material's thermoelectric power factor |

Elevate Your Ceramic Research with KINTEK Precision

Achieving the perfect anisotropic alignment in thermoelectric materials like Ca2.5Ag0.3Sm0.2Co4O9 requires uncompromising thermal stability. KINTEK provides industry-leading high-temperature box and muffle furnaces specifically engineered for long-dwell sintering processes.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory or production needs. Ensure phase purity and maximize your material efficiency today.

Ready to optimize your sintering results? Contact KINTEK for a custom solution.

Visual Guide

References

- Enes Kılınç, Erdal Çelik. Sol–Gel Synthesis of Ca<sub>2.5</sub>Ag<sub>0.3</sub>Sm<sub>0.2</sub>Co<sub>4</sub>O<sub>9</sub> Semiconducting Materials for Thermoelectric Applications in Aerospace Systems. DOI: 10.1002/adem.202500571

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is a high-temperature muffle furnace used in PGC annealing? Optimize Your Phosphor-in-Glass Synthesis

- What is the primary function of a high-temperature muffle furnace for cerium dioxide precursors? Expert Calcination Tips

- What is the primary function of an industrial box furnace? Master 60Si2CrV Spring Steel Heat Treatment

- What is the primary function of a high-temperature furnace for nanocolloid study? Expert Thermal Performance Insights

- What is the purpose of using a high-temperature box resistance furnace for Fe-g-C3N4? Master Thermal Polycondensation

- What role does a high-temperature muffle furnace play during the carbonization of fish scales? Achieve Thermal Precision

- Why is a laboratory muffle furnace essential for the activation of catalysts? Optimize Your Catalyst Performance

- Why are muffle furnaces considered versatile in industrial and laboratory settings? Unlock Precision Heating for Diverse Applications