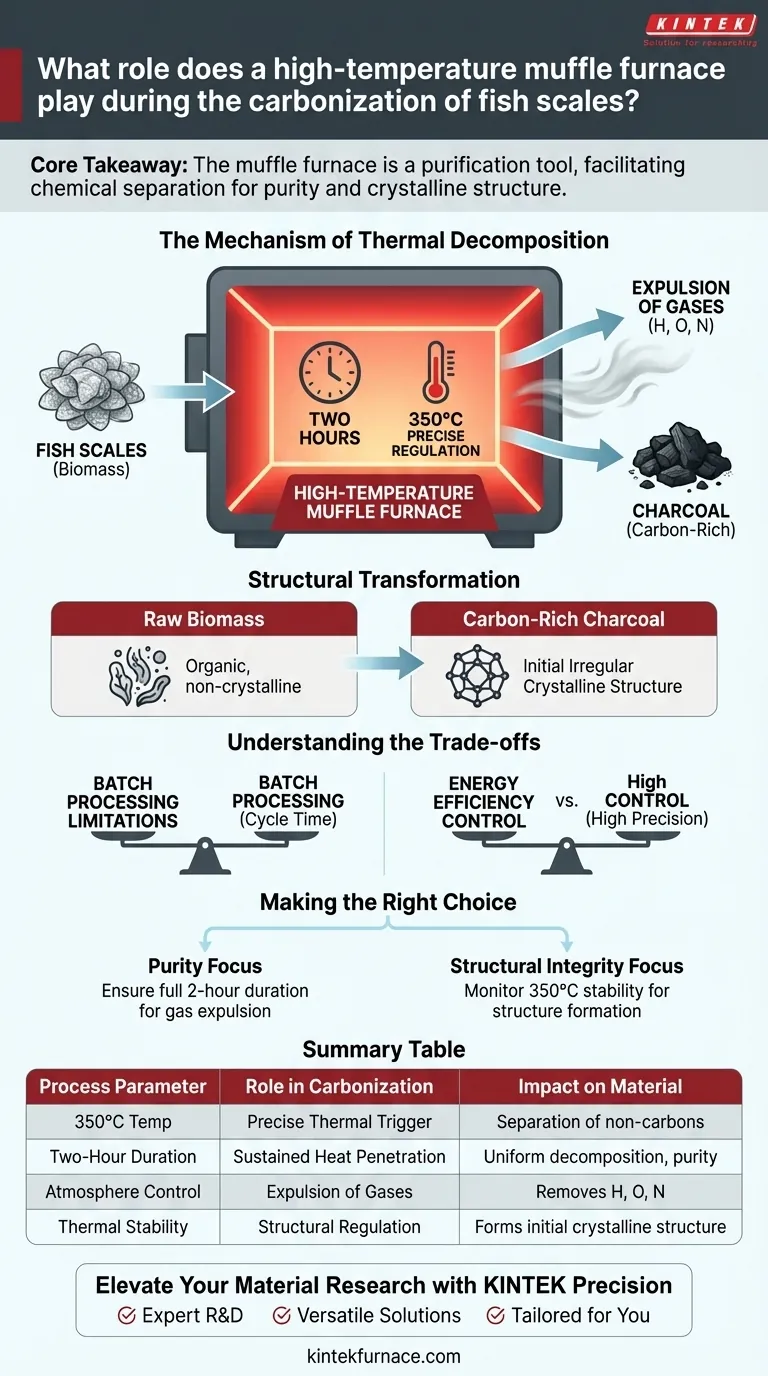

The high-temperature muffle furnace serves as the critical reaction vessel for thermal decomposition during the carbonization of fish scales. By maintaining a precisely stable environment at 350°C for two hours, the furnace drives the expulsion of volatile non-carbon elements to transform raw biomass into carbon-rich charcoal.

Core Takeaway The muffle furnace is not merely a heater; it is a purification tool. Its primary function is to facilitate the chemical separation of carbon from other elements, ensuring the resulting material possesses the necessary purity and initial crystalline structure for further application.

The Mechanism of Thermal Decomposition

To understand the role of the furnace, you must look beyond the heat and focus on the chemical changes it induces.

Precise Temperature Regulation

The carbonization of fish scales requires a specific, stable thermal profile. The muffle furnace maintains a constant temperature of 350°C.

This stability is vital because fluctuations can lead to incomplete carbonization or the destruction of the material structure.

Controlled Duration

The process is time-dependent, requiring a duration of two hours.

This sustained exposure ensures that the thermal energy penetrates the core of the material, rather than just scorching the surface.

Expulsion of Non-Carbon Elements

The heat provided by the muffle furnace triggers thermal decomposition.

This forces elements such as hydrogen, oxygen, and nitrogen to separate from the material structure. These elements are then expelled in gaseous form, leaving the carbon behind.

Structural Transformation

The physical properties of the final product are determined during this heating phase.

Carbon Enrichment

As volatile gases are removed, the relative percentage of carbon in the remaining mass increases significantly.

The muffle furnace effectively concentrates the material, turning raw biological waste into a valuable carbon source.

Crystalline Formation

The process leads to the initial formation of charcoal with an irregular crystalline structure.

While not yet a highly ordered graphite structure, this initial crystallization provides the necessary structural integrity for the charcoal to be used in subsequent applications.

Understanding the Trade-offs

While the muffle furnace is effective, it introduces specific constraints you must account for.

Batch Processing Limitations

Muffle furnaces are typically batch-process units.

This means production is limited by the chamber size and the two-hour cycle time, potentially creating a bottleneck in high-volume manufacturing.

Energy Efficiency vs. Control

Achieving and maintaining 350°C for two hours requires significant energy input.

You are trading energy efficiency for the high precision and stability required to ensure uniform decomposition across the entire batch of fish scales.

Making the Right Choice for Your Goal

The way you utilize the muffle furnace depends on the specific requirements of your end product.

- If your primary focus is Purity: Ensure the furnace maintains the full two-hour duration to guarantee the complete expulsion of hydrogen, oxygen, and nitrogen.

- If your primary focus is Structural Integrity: Monitor the temperature stability at 350°C rigorously, as deviations can alter the formation of the irregular crystalline structure.

The muffle furnace provides the essential controlled environment required to convert biological waste into a stable, carbon-enriched material.

Summary Table:

| Process Parameter | Role in Carbonization | Impact on Material |

|---|---|---|

| 350°C Temperature | Precise Thermal Trigger | Separation of volatile non-carbon elements |

| Two-Hour Duration | Sustained Heat Penetration | Ensures uniform decomposition and core purity |

| Atmosphere Control | Expulsion of Gases | Removes Hydrogen, Oxygen, and Nitrogen |

| Thermal Stability | Structural Regulation | Forms initial irregular crystalline structure |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your carbonization processes with KINTEK’s industry-leading thermal solutions. Whether you are transforming biomass or developing advanced crystalline structures, our systems provide the stability and control required for superior results.

Why choose KINTEK?

- Expert R&D & Manufacturing: Decades of experience in high-temperature lab equipment.

- Versatile Solutions: From Muffle and Tube furnaces to Rotary, Vacuum, and CVD systems.

- Tailored for You: Fully customizable systems designed to meet your unique experimental or production needs.

Ready to optimize your carbonization workflow? Contact us today to find the perfect furnace for your application!

Visual Guide

References

- Jolantje Latupeirissa, Muliana Muliana. CHARACTERISATION OF ACTIVATED CARBON FROM WHITE SNAPPER SCALES (Lates calcarife) WASTE. DOI: 10.30872/jkm.v21i2.1292

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the common uses of box type electric furnaces in heat treatment processes? Achieve Precise Material Property Control

- Why is a muffle furnace essential for the combustion step in the preparation of perovskite catalysts?

- What safety features should be considered when selecting a muffle furnace? Ensure Lab Safety with Advanced Protection Systems

- What is the working principle of the box furnace's door mechanism? Ensure Safety and Efficiency in Your Lab

- What are the advantages of muffle furnaces compared to other heating devices? Superior Temperature Control and Purity

- What precautions should be taken while using muffle furnace? Ensure Complete Safety and Longevity

- What is the function of a high-temperature muffle furnace? Master Polycrystalline MgSiO3 and Mg2SiO4 Synthesis

- Why is it important to check the power supply of a muffle furnace? Ensure Safety and Accurate Results