In the realm of materials science, the box type electric furnace is a cornerstone for fundamental heat treatment processes. It is most commonly used for quenching, annealing, and solution treatment of metals to precisely modify their physical and chemical properties, such as improving hardness, strength, and corrosion resistance.

The core challenge in heat treatment is achieving repeatable and uniform material properties. A box type electric furnace addresses this by providing a highly controlled and stable thermal environment, making it an indispensable tool for labs and batch production, though its effectiveness depends on correctly matching its features to the specific process requirements.

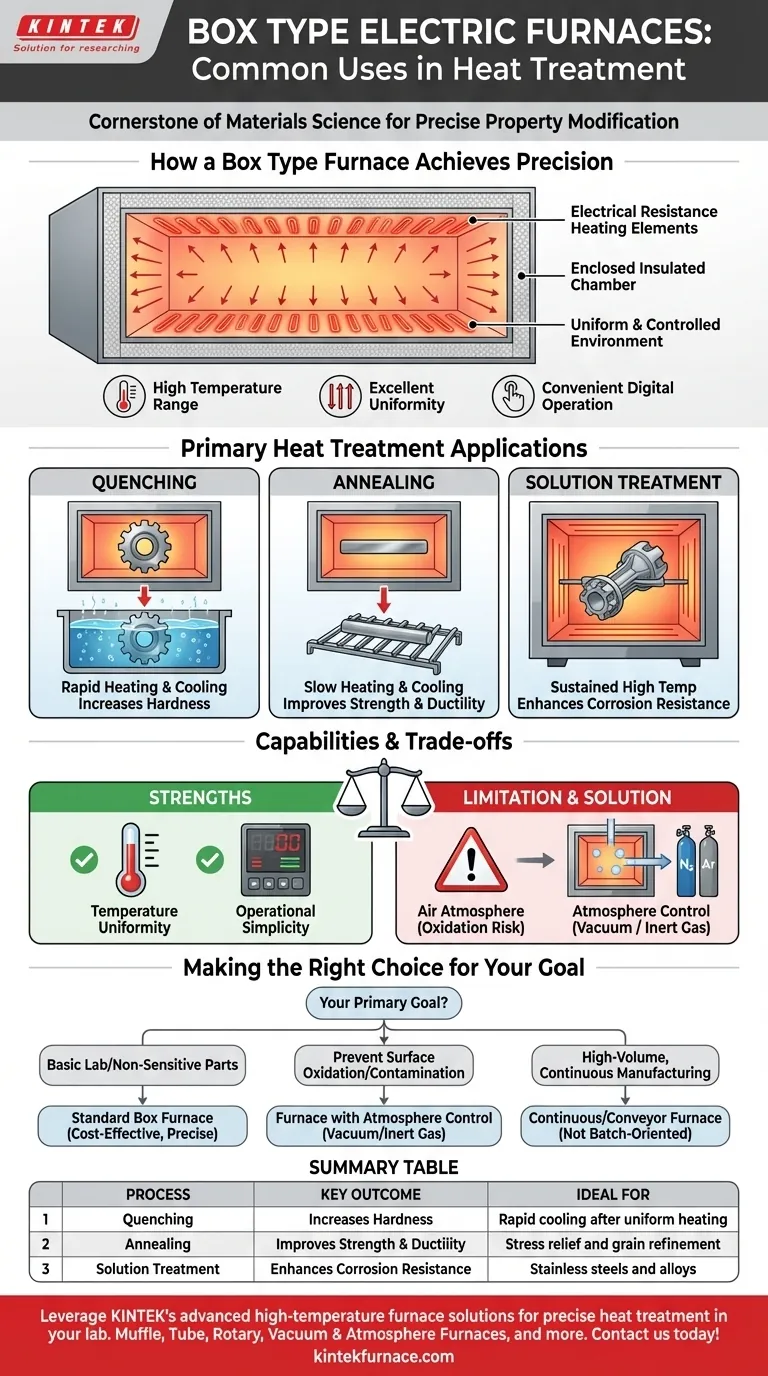

How a Box Type Furnace Achieves Precision

A box type furnace, often compared to a high-precision industrial oven, operates on a straightforward yet effective principle. Understanding its mechanics is key to appreciating its role.

The Heating Mechanism

The furnace generates heat using electrical resistance. An electric current is passed through specialized heating elements—which can be resistance wires, plates, or graphite—causing them to heat up and radiate energy into the chamber.

This method allows for very fine and responsive control over the temperature inside the furnace, which is critical for executing precise heat treatment cycles.

The Enclosed Chamber Design

The "box" itself is an insulated chamber designed to minimize heat loss and ensure a stable environment. This enclosure is what allows the internal temperature to reach high levels and, more importantly, to be held there uniformly.

Key Operational Characteristics

Modern box furnaces are valued for three primary characteristics mentioned in the references: a high temperature range, excellent temperature uniformity across the chamber, and convenient operation via user-friendly digital controls.

Primary Heat Treatment Applications

The controlled environment of a box furnace makes it ideal for several foundational processes, each designed to achieve a different metallurgical outcome.

Quenching for Hardness

Quenching involves heating a metal to a specific temperature and then rapidly cooling it. A box furnace is used for the critical heating phase, ensuring the entire part reaches the correct temperature uniformly before the cooling process begins. This results in a significant increase in the metal's hardness.

Annealing for Strength and Ductility

Annealing is a process of heating and slow cooling. It is used to soften metals, relieve internal stresses, and refine the grain structure. This makes the material more ductile and less brittle, improving its overall strength and workability.

Solution Treatment for Corrosion Resistance

Primarily used for stainless steels and certain alloys, solution treatment involves heating the material to dissolve inconsistencies in its structure into a solid solution. The box furnace provides the sustained, high-temperature environment needed for this process, which significantly enhances the material's corrosion resistance.

Understanding the Capabilities and Trade-offs

While versatile, a box furnace is not a universal solution. Its strengths are balanced by inherent limitations that you must consider for your application.

Strength: Temperature Uniformity

Its greatest strength is the ability to maintain a uniform temperature throughout the chamber. This ensures that an entire component or a full batch of smaller parts receives the exact same thermal treatment, leading to consistent and predictable final properties.

Strength: Operational Simplicity

With modern digital controllers, these furnaces are relatively simple to operate. They are ideal for laboratory experiments, research and development, and small-to-medium batch production where processes change frequently.

Limitation: The Atmosphere

A standard box furnace operates with an air atmosphere. For many metals, heating in the presence of oxygen can cause undesirable scaling and oxidation. While this is acceptable for some processes, it is a critical limitation for others.

Overcoming the Limitation: Atmosphere Control

To address this, some models can be equipped with sealed structures and atmosphere control systems. These advanced furnaces allow for heat treatment in a vacuum or under a blanket of protective gases like nitrogen or argon, preventing surface reactions.

Making the Right Choice for Your Goal

Selecting the correct furnace configuration is critical for success. Your choice should be dictated by the material you are treating and your desired outcome.

- If your primary focus is basic heat treatment in a lab or for non-sensitive parts: A standard box type furnace is an excellent, cost-effective tool that offers the necessary precision.

- If your primary focus is preventing any surface oxidation or contamination: You must specify a furnace model equipped with vacuum or inert gas atmosphere control.

- If your primary focus is high-volume, continuous manufacturing: The batch-oriented nature of a box furnace is likely a bottleneck, and a continuous or conveyor-style furnace would be a more appropriate choice.

Ultimately, understanding these capabilities allows you to leverage the box type electric furnace as a precise and reliable tool for achieving your desired metallurgical outcomes.

Summary Table:

| Process | Key Outcome | Ideal For |

|---|---|---|

| Quenching | Increases hardness | Rapid cooling after uniform heating |

| Annealing | Improves strength and ductility | Stress relief and grain refinement |

| Solution Treatment | Enhances corrosion resistance | Stainless steels and alloys |

Leverage KINTEK's advanced high-temperature furnace solutions for precise heat treatment in your lab. Our diverse product line, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is backed by strong deep customization to meet your unique experimental needs. Contact us today to enhance your material properties with reliable, uniform heating!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production