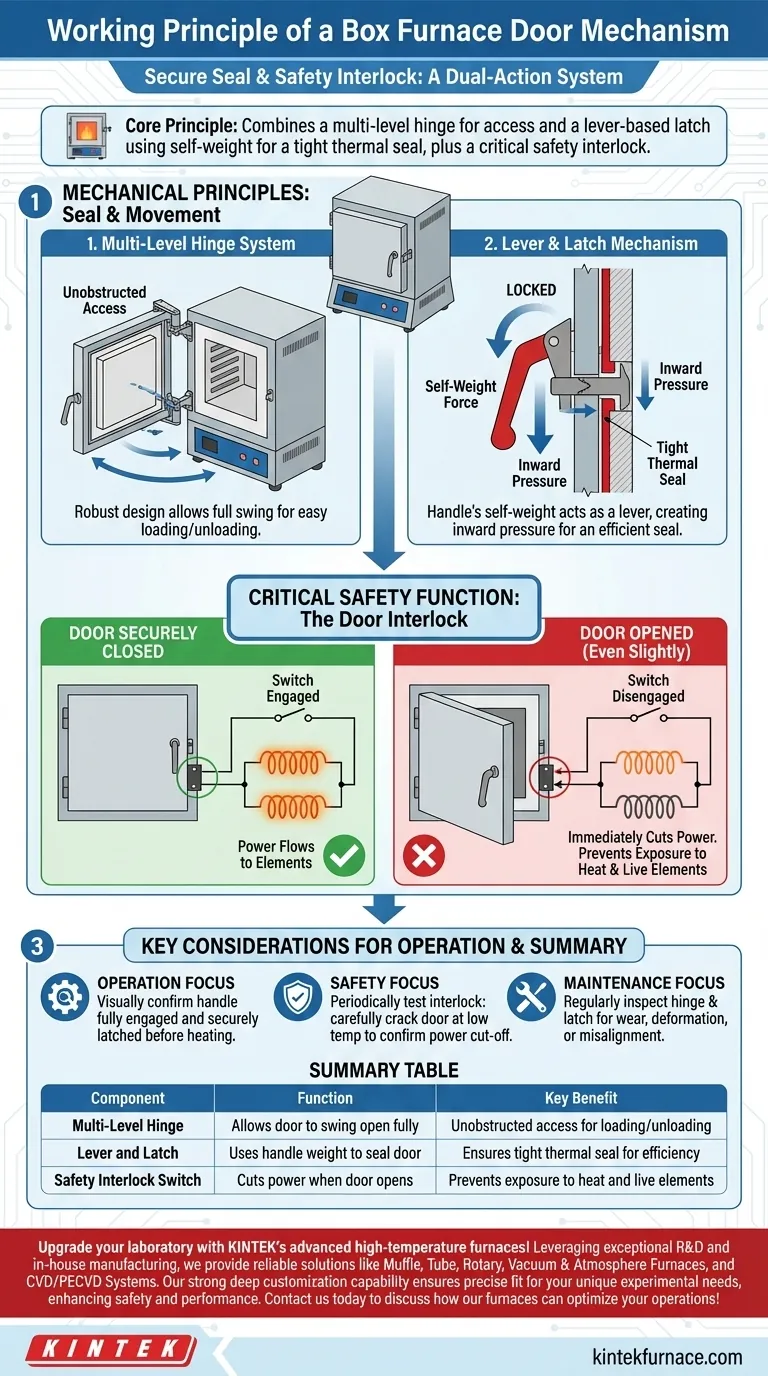

At its core, the working principle of a box furnace door mechanism relies on a simple yet effective combination of a multi-level hinge and a lever-based latch. The door is closed and sealed securely by using the self-weight of the handle, which acts as a lever to press the door firmly against the furnace body. This design ensures a tight seal for thermal efficiency and incorporates a critical safety interlock.

The furnace door mechanism is designed for two primary functions: creating a tight thermal seal through a simple lever action and ensuring operator safety by automatically cutting power via an interlock switch whenever the door is opened.

The Core Mechanical Principles

To understand the door's function, we must look at its two key mechanical components: the hinge and the latching system. Together, they provide both movement and a secure seal.

The Hinge System

The furnace door is attached to the main body using a multi-level hinge. This robust design allows the door to swing completely open, typically to the side, providing unobstructed access to the furnace chamber for loading and unloading materials.

The Lever and Latch Mechanism

The sealing force is not generated by a complex lock but by the lever principle. The door handle is designed so that its own weight, when lowered into the locked position, applies downward force on a latching mechanism. This force translates into inward pressure, pressing the door tightly against the furnace opening.

Opening the Furnace Door

The process is a simple reversal. To open the door, an operator lifts the handle upward, which disengages the latch. Once the pressure is released, the door can be freely swung open on its hinge.

The Critical Safety Function

Beyond the mechanics of sealing, the door mechanism's most important feature is its integrated safety system. This is not an optional component; it is fundamental to safe operation.

The Door Interlock Switch

Nearly all modern box furnaces are equipped with a safety interlock switch. This switch is typically a small mechanical or proximity sensor located at the base or side of the furnace door opening.

How the Interlock Protects Operators

The interlock is wired directly into the furnace's power circuit for the heating elements. When the door is securely closed, the switch is engaged, allowing power to flow to the elements. The moment the door is opened, even slightly, the switch disengages and immediately cuts power. This prevents operator exposure to extreme temperatures and direct contact with live electrical heating elements.

Understanding the Design Context

This seemingly simple design is a deliberate engineering choice that balances efficiency, cost, and safety.

Why a Tight Seal is Essential

A poor seal is the enemy of any furnace. Heat loss leads directly to wasted energy and difficulty in maintaining a stable, uniform temperature inside the chamber. For atmosphere furnaces, a tight seal is even more critical to prevent the controlled internal atmosphere (e.g., inert gas) from escaping or being contaminated by outside air.

Manual vs. Automated Doors

The lever-and-hinge mechanism described is standard for most laboratory and small-scale production box furnaces where doors are operated manually. Larger industrial furnaces may feature more complex, automated door systems that are pneumatically or hydraulically operated, though they still incorporate the same fundamental safety interlocks.

Key Considerations for Operation

Understanding the door's function is key to using the furnace safely and effectively.

- If your primary focus is routine operation: Always visually confirm the handle is fully engaged and the door is securely latched before starting a heating cycle.

- If your primary focus is safety verification: Periodically test the interlock switch by starting a cycle at a low temperature and carefully cracking the door open to confirm that power to the heaters cuts off immediately.

- If your primary focus is maintenance: Regularly inspect the hinge and latch components for signs of wear, deformation, or misalignment that could compromise the seal or safety function.

Ultimately, the furnace door is an elegant system designed to perform the dual role of containing immense heat while guaranteeing operator safety.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Multi-Level Hinge | Allows door to swing open fully | Unobstructed access for loading/unloading |

| Lever and Latch | Uses handle weight to seal door | Ensures tight thermal seal for efficiency |

| Safety Interlock Switch | Cuts power when door opens | Prevents exposure to heat and live elements |

Upgrade your laboratory with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, enhancing safety and performance. Contact us today to discuss how our furnaces can optimize your operations!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- Why is a high-temperature muffle furnace typically selected for annealing? Achieve Optimal Ceramic Performance

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- What is the role of a muffle furnace in synthesizing P2-Na0.67Ni0.33Mn0.67O2? Key to High-Performance Cathodes