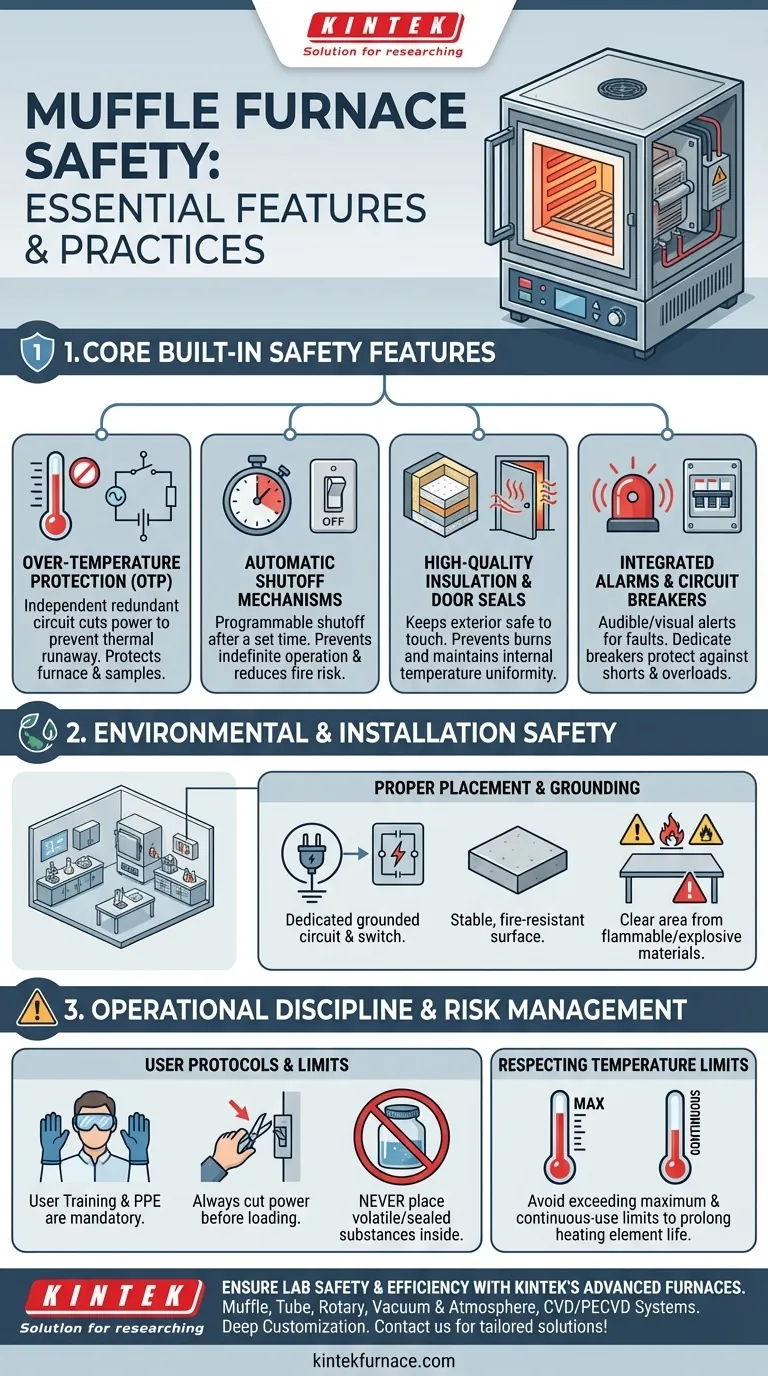

When selecting a muffle furnace, your primary considerations must be the integrated safety systems designed to prevent catastrophic failure. The most critical features include automatic over-temperature protection, independent shutoff mechanisms, high-quality thermal insulation, effective door seals, and properly rated electrical circuit breakers. These components work together to protect the user, the samples, and the lab environment from the inherent risks of high-temperature operation.

A muffle furnace's safety is not defined by a single feature, but by a complete system. True safety is achieved by combining the right built-in hardware with correct installation and disciplined operational protocols.

Core Built-in Safety Features Explained

Understanding a furnace's internal safety mechanisms is the first step in making an informed selection. These are the non-negotiable features that act as the first line of defense against accidents.

Over-Temperature Protection (OTP)

Over-temperature protection is arguably the single most important safety feature. It functions as a redundant safety circuit, independent of the primary temperature controller.

If the main controller fails and calls for continuous heat, the OTP circuit will cut power to the heating elements once a user-set, higher temperature limit is reached. This prevents thermal runaway, protecting the furnace from self-destruction and the samples from being ruined.

Automatic Shutoff Mechanisms

This feature allows for "walk-away" operation. A furnace with automatic shutoff can be programmed to turn off after a specific time interval has elapsed.

This not only ensures process consistency but also prevents the furnace from running indefinitely if forgotten, which reduces energy consumption and minimizes fire risk.

High-Quality Insulation and Door Seals

Effective insulation is crucial for both energy efficiency and user safety. High-quality, low-density ceramic fiber insulation ensures the exterior casing of the furnace remains at a safe-to-touch temperature.

A tight-fitting door seal complements the insulation. It prevents heat from escaping, which maintains temperature uniformity inside the chamber and, more importantly, protects the operator from burns and exposure to extreme heat when near the unit.

Integrated Alarms and Circuit Breakers

Audible and visual alarms provide immediate notification of a fault condition, such as an over-temperature event. This allows for swift operator intervention.

Dedicated electrical circuit breakers or fuses matched to the furnace's power draw protect against electrical shorts and overloads, preventing electrical fires and damage to the building's wiring.

Environmental and Installation Safety

The safety features of the furnace itself are only half of the equation. Where and how you install the unit is equally critical for safe, long-term operation.

Proper Electrical Grounding and Circuits

A muffle furnace is a high-power device that must be properly grounded to prevent risk of electric shock.

It should be connected to a dedicated electrical circuit with an appropriate fuse or breaker. Using a dedicated power control gate or switch allows you to cut all power to the unit quickly in an emergency.

Stable Placement and a Safe Workspace

The furnace must be placed on a sturdy, level, and fire-resistant surface, such as a concrete platform or a specialized lab bench.

Crucially, the surrounding area must be kept clear of all flammable, explosive, or corrosive materials. Good housekeeping is a foundational safety practice.

Understanding the Trade-offs and Operational Risks

Even the most advanced furnace is only as safe as the person operating it. Relying solely on built-in features while ignoring operational discipline creates a false sense of security.

Feature Reliance vs. User Discipline

Never assume a safety feature will compensate for poor procedure. Users must be trained on the furnace's specific operation, including how to set the OTP correctly.

Strict protocols, such as always cutting power before loading or unloading samples, wearing appropriate personal protective equipment (PPE) like heat-resistant gloves, and minimizing the time the door is open, are mandatory.

The Hidden Danger of Sample Volatility

Never place sealed containers, liquids, or highly volatile or oily substances inside a muffle furnace.

The rapid heating can cause a sudden pressure increase inside a sample or produce flammable vapors, creating a risk of explosion or fire that built-in features cannot prevent.

Respecting Temperature Limits

Every furnace has a maximum temperature and a lower continuous-use rated temperature. Exceeding the absolute maximum, or running the furnace at its rated temperature for excessively long periods, will drastically shorten the life of heating elements and refractory materials.

If you observe any abnormalities in temperature rise or instrument behavior, cut power immediately and investigate the cause.

Making the Right Choice for Your Application

Your choice of furnace should be guided by a realistic assessment of your application and your lab's operational discipline.

- If your primary focus is routine, repetitive tasks: Prioritize a furnace with robust programming, automatic shutoff timers, and clear alarms to ensure process consistency and safety.

- If your primary focus is research with variable materials: Invest in a model with a highly responsive, independent over-temperature protection circuit and superior chamber insulation.

- If your primary focus is adherence to strict safety standards: Ensure the furnace not only has all core features but is also certified by a recognized body (e.g., UL, CE) and pair it with rigorous, documented user training.

Ultimately, remember that safety is an active process, not a passive feature you can simply purchase.

Summary Table:

| Safety Feature | Key Benefit |

|---|---|

| Over-Temperature Protection | Prevents thermal runaway and equipment damage |

| Automatic Shutoff | Reduces fire risk and energy waste |

| High-Quality Insulation | Maintains safe exterior temperatures |

| Door Seals | Protects operators from burns |

| Circuit Breakers | Prevents electrical fires and overloads |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, enhancing reliability and performance. Contact us today to discuss how we can support your specific requirements and elevate your operations!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production