To safely use a muffle furnace, you must implement a comprehensive set of precautions covering electrical installation, the operating environment, material handling, and shutdown procedures. Key actions include ensuring the furnace is properly grounded on a stable surface, keeping the workspace free of flammable materials, never exceeding the maximum temperature rating, and using appropriate personal protective equipment like thermal gloves.

A muffle furnace is a powerful tool, but its high temperatures and electrical demands introduce significant risks. True safety is not about a single action, but a systematic approach that treats the environment, the equipment, and the operational procedure with equal respect.

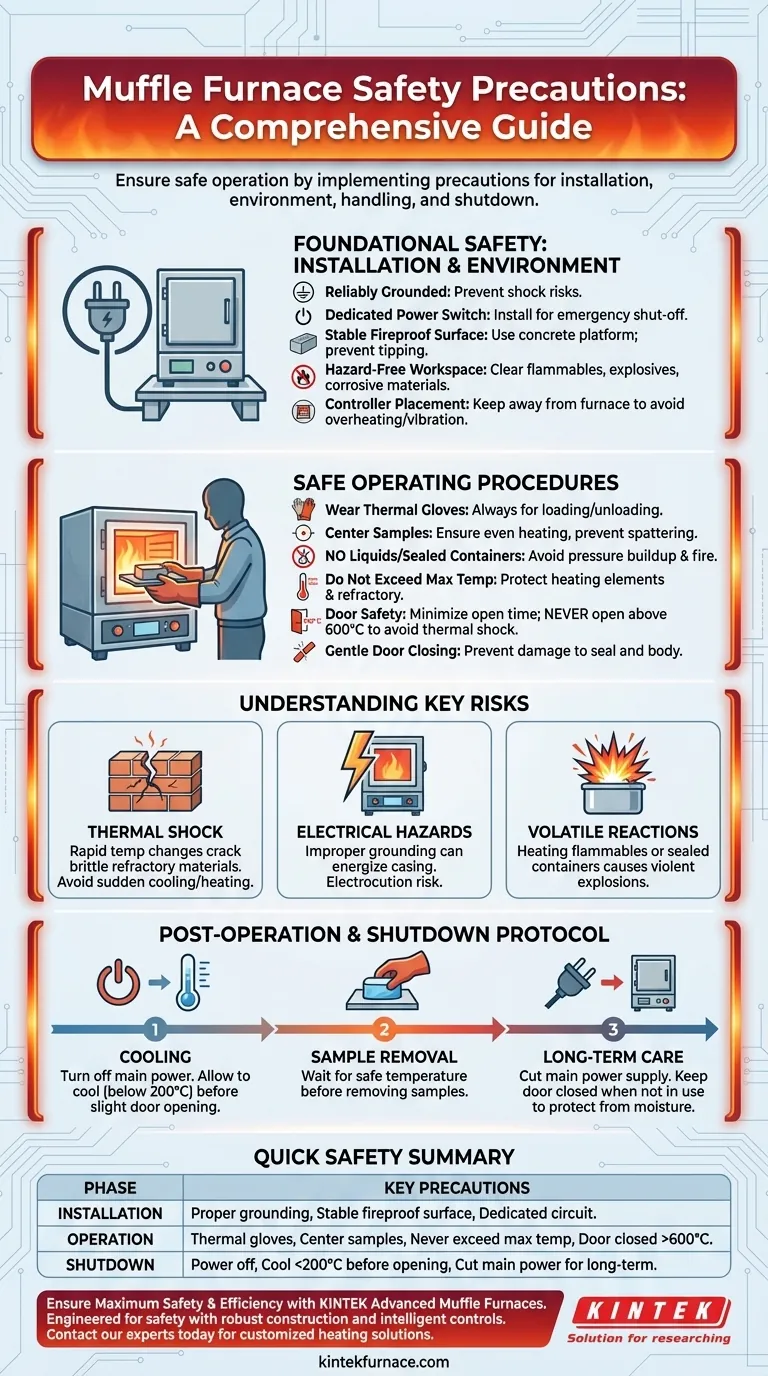

Foundational Safety: Installation and Environment

Before you ever turn the furnace on, safety begins with its physical and electrical setup. A poor foundation will undermine all subsequent safety efforts.

Proper Electrical Connection and Grounding

The furnace and its controller must be reliably grounded to prevent the risk of electric shock.

An additional, dedicated power switch or circuit breaker should be installed at the power line inlet. This allows you to cut all power to the unit in an emergency.

Ensure you use plugs, sockets, and fuses that are rated for the furnace's power requirements to prevent overloading circuits and creating a fire hazard.

Stable and Safe Placement

Place the furnace on a stable, level, and fireproof surface, such as a concrete platform. This prevents tipping and ensures stability during operation.

The controller should be located away from the furnace to avoid vibration and overheating, which can cause electronic components to fail.

Creating a Hazard-Free Workspace

The area around the muffle furnace must be completely free of flammable, explosive, or corrosive materials. High temperatures can easily ignite nearby hazards.

Never store dangerous goods near the furnace, and ensure the workspace has adequate ventilation.

Safe Operating Procedures

During operation, your direct interaction with the furnace is the most critical phase for safety. Adherence to strict protocols is non-negotiable.

Handling Samples and Loading the Furnace

Always wear appropriate thermal gloves when loading or unloading samples to prevent severe burns.

Place samples neatly in the center of the furnace hearth to ensure even heating and stability.

Never place liquids, sealed containers, or excessively oily samples inside the furnace. This can cause spattering, pressure buildup, or fire.

Managing Temperature and Heating Cycles

Do not exceed the maximum rated temperature of the furnace. This can cause permanent damage to the heating elements and refractory materials.

Avoid operating the furnace at its maximum temperature for extended periods, as this shortens its operational life.

Monitor temperature changes closely. If you notice any abnormalities or unexpected fluctuations, cut power immediately and investigate the cause.

Interacting with the Furnace Door

When the furnace is operating, especially at high temperatures, minimize the time the door is open. This preserves heat and protects the user from intense thermal radiation.

As a strict rule, do not open the furnace door at temperatures above 600°C. The rapid temperature change can cause thermal shock, cracking the refractory lining.

Always close the furnace door gently to avoid damaging the door seal and furnace body.

Understanding Key Risks and Trade-offs

Understanding why these rules exist is crucial for developing an instinct for safety. The primary risks involve thermal shock, electrical hazards, and volatile reactions.

The Risk of Thermal Shock

The refractory materials inside a furnace are ceramic and brittle. Rapid temperature changes, such as opening the door at high heat or introducing a cold or wet sample, can cause them to crack or shatter. This is an expensive and time-consuming repair.

The Danger of Unseen Electrical Hazards

A muffle furnace draws a significant amount of electrical power. Without proper grounding, a fault in the wiring could energize the entire metal casing of the furnace, creating a lethal risk of electrocution. A dedicated circuit prevents overloading and potential fires elsewhere in the building.

The Threat of Volatile Materials

Heating a flammable material or a sealed container is extremely dangerous. Flammables can auto-ignite, and a sealed container will experience a massive pressure buildup, potentially turning it into a projectile and causing a violent explosion that can destroy the furnace and harm personnel.

Post-Operation and Shutdown Protocol

Proper shutdown is just as important as the heating process. It ensures the longevity of the equipment and the safety of the next user.

Cooling the Furnace Safely

After the heating cycle is complete, turn off the main power.

You may slightly open the furnace door to allow it to cool down more quickly, but only after the temperature has dropped to a safe level (e.g., below 200°C).

Removing Samples

Wait until the furnace has cooled to a safe temperature before removing your samples, even when wearing gloves. Handling extremely hot items increases the risk of accidents and burns.

Long-Term Care

When the furnace is not in use for an extended period, ensure the main power supply is cut off.

Keep the furnace door closed when not in use. This protects the delicate refractory materials inside from moisture and physical damage.

Making the Right Choice for Your Goal

Your specific safety focus will depend on your role and immediate task.

- If your primary focus is personal safety: Prioritize wearing thermal gloves, adhering to the door-opening temperature limits, and verifying the unit is properly grounded.

- If your primary focus is protecting the equipment: Never exceed the maximum temperature, avoid rapid heating or cooling cycles, and keep the door closed when not in use.

- If your primary focus is maintaining a safe lab environment: Ensure the area is clear of all flammables and never heat liquids or sealed containers inside the furnace.

Ultimately, consistent and disciplined adherence to these procedures is the only way to guarantee safe and effective operation of a muffle furnace.

Summary Table:

| Safety Phase | Key Precautions |

|---|---|

| Installation | Proper grounding, stable fireproof surface, dedicated power circuit |

| Operation | Thermal gloves, center sample placement, never exceed max temperature |

| Shutdown | Power off, cool below 200°C before opening door, cut main power when not in use |

Ensure your laboratory operates with maximum safety and efficiency. KINTEK's advanced muffle furnaces are engineered with safety as a core principle, featuring robust construction and intelligent controls that support proper operational protocols. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact our experts today to discuss how our reliable and safe heating solutions can benefit your lab.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites