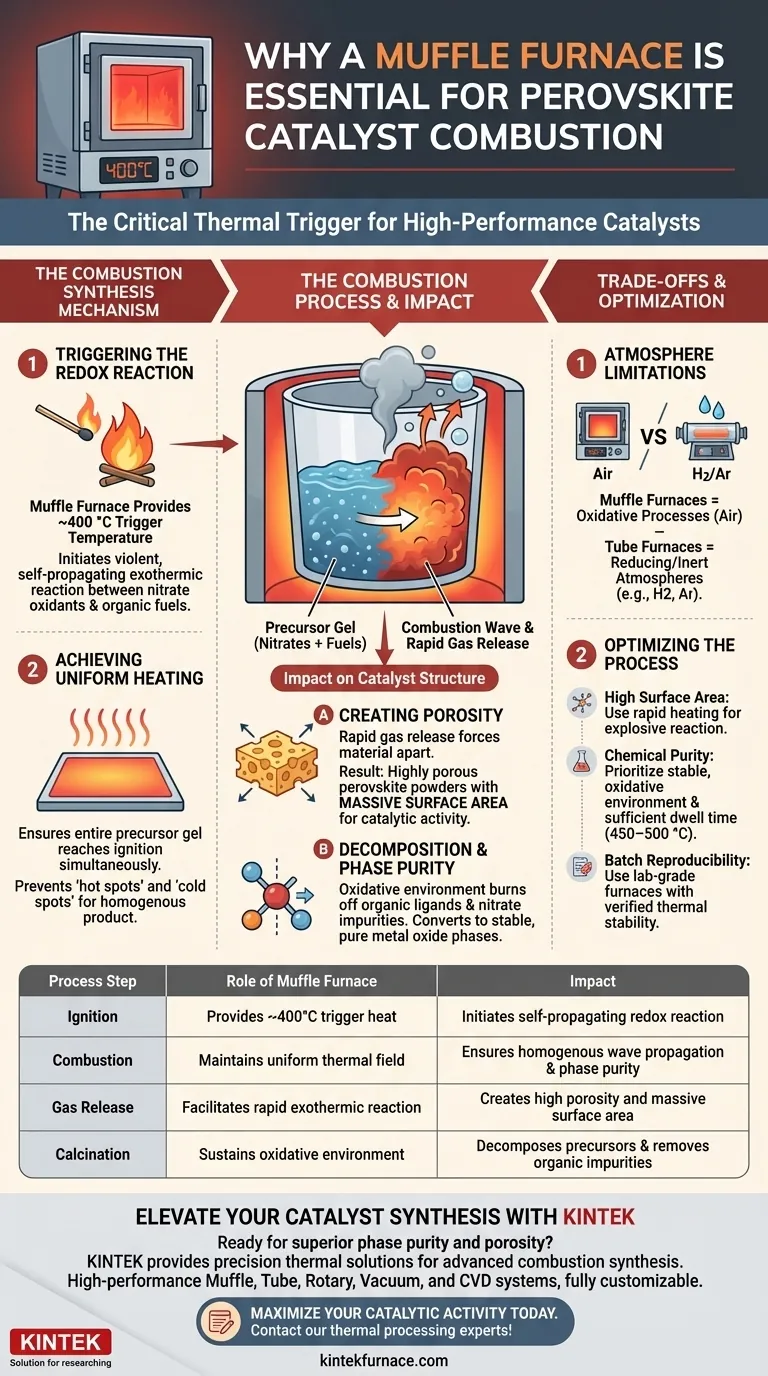

A muffle furnace serves as the critical thermal trigger in the preparation of perovskite catalysts, specifically during the combustion step. It provides a strictly controlled, uniform high-temperature environment—typically around 400 °C—that is necessary to initiate a self-propagating combustion reaction. This precise heating ensures that the precursor gel undergoes a rapid redox reaction, converting a liquid or gel mixture into a solid catalyst structure.

The Core Insight The muffle furnace is not merely a heating device; it functions as a reactor that sustains a "combustion wave" between nitrate oxidants and organic fuels. This rapid reaction instantly releases gases, creating the high porosity and massive surface area that define a high-quality perovskite catalyst.

The Mechanics of Combustion Synthesis

Triggering the Redox Reaction

The primary role of the muffle furnace is to raise the precursor gel to its ignition point, generally near 400 °C.

At this temperature, the furnace triggers a violent, self-propagating reaction between the nitrate oxidants and the organic fuels within the mixture. This reaction is exothermic, meaning it generates its own heat once started, but it requires the furnace's reliable ambient heat to initiate effectively.

Achieving Uniform Heating

Success in combustion synthesis relies on the entire sample reaching the ignition temperature simultaneously or in a controlled wave.

The muffle furnace is designed for uniform heating, which prevents localized "hot spots" or "cold spots" in the precursor gel. Uniformity ensures that the combustion wave propagates evenly through the material, leading to a homogenous final product rather than a mixture of unreacted gel and burnt ash.

Impact on Catalyst Structure

Creating Porosity Through Gas Release

The effectiveness of a perovskite catalyst is often determined by its surface area.

The rapid and intense redox reaction facilitated by the muffle furnace causes a sudden release of gases. This gas expansion forces the material apart as it solidifies, resulting in highly porous perovskite powders with a large surface area, which is essential for catalytic activity.

Decomposition and Phase Purity

Beyond physical structure, the furnace ensures chemical purity.

The oxidative environment (air) within the furnace facilitates the complete decomposition of metal salt precursors. It effectively burns off organic ligands and nitrate impurities, converting the mixture into stable metal oxide phases and establishing the preliminary skeletal structure of the catalyst.

Understanding the Trade-offs

Atmosphere Limitations

While muffle furnaces excel at oxidative processes like combustion and calcination, they have limitations regarding atmosphere control.

If your process requires a reducing atmosphere (e.g., introducing Hydrogen or Argon to remove oxygen groups), a tube furnace is the superior choice. Muffle furnaces generally operate with ambient air, making them unsuitable for steps requiring strict oxygen exclusion or hydrogen reduction.

Batch Consistency Challenges

In laboratory settings, muffle furnaces offer excellent thermal field stability, ensuring consistency between small batches.

However, when scaling to larger industrial muffle furnaces, maintaining that same degree of uniformity can be challenging. Without precise management, temperature gradients may develop, potentially leading to inconsistencies in the catalyst's phase composition across larger production volumes.

Optimizing the Preparation Process

To ensure the best results during the combustion step, align your equipment usage with your specific material goals:

- If your primary focus is high surface area: Ensure the furnace is pre-heated or capable of rapid heating rates to trigger an explosive, gas-releasing reaction rather than a slow decomposition.

- If your primary focus is chemical purity: Prioritize a stable, oxidative environment with sufficient dwell time (around 450–500 °C) to fully burn off organic residues and nitrate impurities.

- If your primary focus is batch reproducibility: Use a laboratory-grade muffle furnace with verified thermal field stability to minimize variables between experimental runs.

By controlling the thermal environment with precision, you transform a simple chemical mixture into a sophisticated, high-performance catalytic architecture.

Summary Table:

| Process Step | Role of Muffle Furnace | Impact on Perovskite Catalyst |

|---|---|---|

| Ignition | Provides ~400°C trigger heat | Initiates self-propagating redox reaction |

| Combustion | Maintains uniform thermal field | Ensures homogenous wave propagation & phase purity |

| Gas Release | Facilitates rapid exothermic reaction | Creates high porosity and massive surface area |

| Calcination | Sustains oxidative environment | Decomposes precursors & removes organic impurities |

Elevate Your Catalyst Synthesis with KINTEK

Ready to achieve superior phase purity and porosity in your perovskite materials? KINTEK provides the precision thermal solutions required for advanced combustion synthesis. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory or industrial needs.

Maximize your catalytic activity today. Contact our thermal processing experts to find your perfect furnace solution!

Visual Guide

References

- Pradeep Kumar Yadav, Sudhanshu Sharma. Effect of Partial Noble Metal (M = Pd, Rh, Ru, Pt) Substitution in La1−xSrxCo1−yMyO3 Perovskite-Derived Catalysts for Dry Reforming of Methane. DOI: 10.3390/hydrogen6030049

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the primary process objectives when using a laboratory high-temperature Muffle Furnace for precursor treatment?

- What role does a muffle furnace play in RH-SNP preparation? Master the Dual-Stage Thermal Synthesis

- What are the primary functions of laboratory resistance furnaces in lead refining? Achieve 700°C Thermal Precision

- How are muffle furnaces used in high-temperature sintering within the pharmaceutical industry? Ensure Precision and Purity in Drug Development

- What are the common applications of benchtop furnaces? Unlock Precision in Materials Science and More

- What is the function of a vacuum box resistance furnace in the preparation of Pine Nut Shell Biochar (PBC)?

- How does the constant temperature environment of a box high-temperature furnace contribute to phase transformation?

- How is the muffle furnace packaged for shipping? Ensuring Safe Delivery for Your Lab Equipment