The primary function of a vacuum box resistance furnace in this context is to execute the vacuum carbonization of pine nut shells. By maintaining a high-temperature environment of approximately 400°C, the furnace thermally decomposes the raw biomass into Pine Nut Shell Biochar (PBC) without combustion.

Core Takeaway The vacuum box resistance furnace is not merely a heating element; it is an oxidation shield. Its defining role is to facilitate pyrolysis in an oxygen-free environment, ensuring the resulting biochar retains the high specific surface area and electrical conductivity necessary for use as an anode substrate.

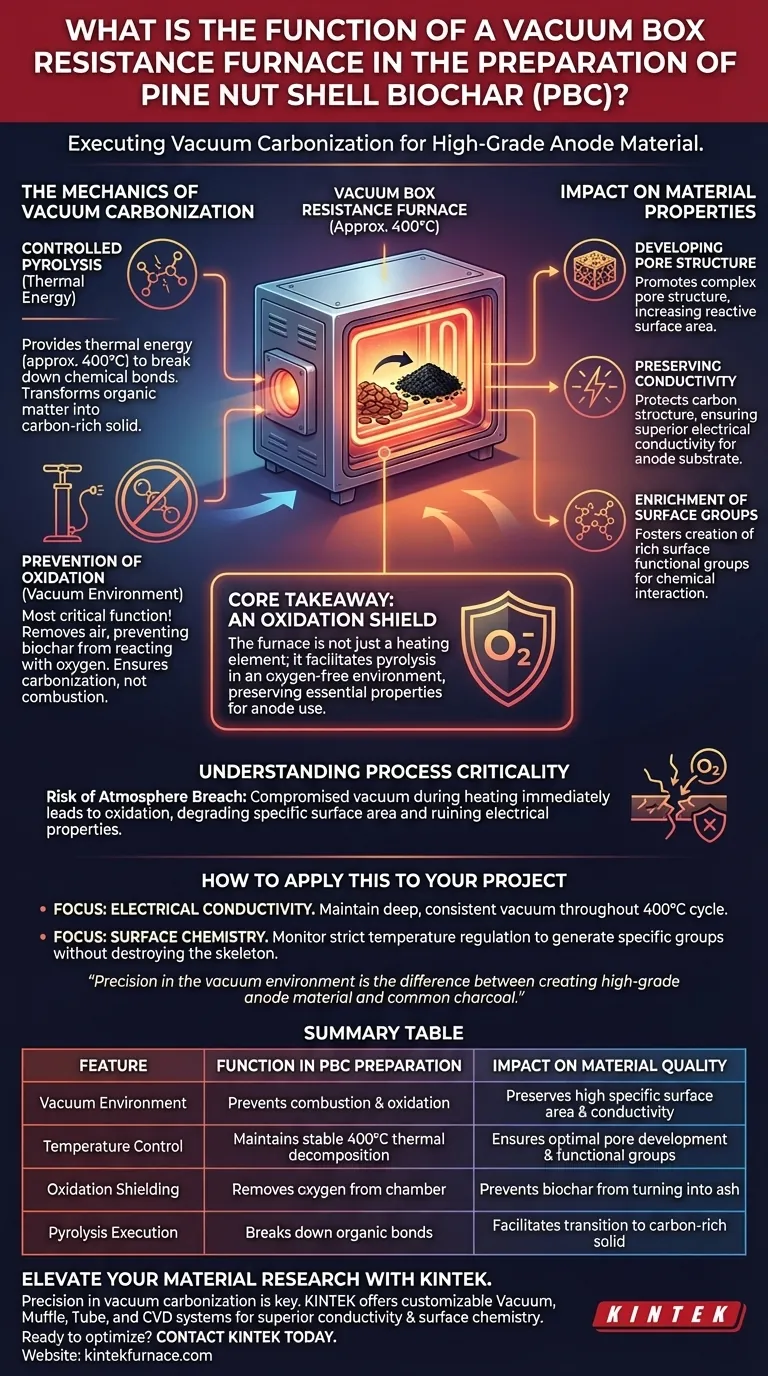

The Mechanics of Vacuum Carbonization

Controlled Pyrolysis

The furnace provides the thermal energy required to break down the chemical bonds within the pine nut shells.

Operating at approximately 400°C, the equipment initiates the transformation of organic matter into carbon-rich solid material.

Prevention of Oxidation

The most critical function of this specific furnace type is the creation of a vacuum environment.

By removing air from the chamber, the furnace prevents the biochar from reacting with oxygen. This ensures the material undergoes carbonization rather than combustion (burning to ash).

Impact on Material Properties

Developing Pore Structure

The vacuum carbonization process directly influences the physical architecture of the biochar.

The furnace environment promotes the development of a complex pore structure, which is essential for increasing the material's reactive surface area.

Preserving Conductivity

The vacuum environment protects the carbon structure from degrading at high temperatures.

This preservation ensures the final PBC possesses superior electrical conductivity, a requirement for its application as an anode substrate in electronic components.

Enrichment of Surface Groups

Beyond structure, the process affects the chemical composition of the char.

The controlled heating profile fosters the creation of rich surface functional groups, which determine how the biochar interacts chemically with other materials.

Understanding the Process Criticality

The Risk of Atmosphere Breach

The effectiveness of this furnace relies entirely on the integrity of the vacuum seal.

If the vacuum is compromised during the 400°C heating phase, oxygen ingress will immediately lead to oxidation. This degrades the specific surface area and ruins the electrical properties required for anode applications.

How to Apply This to Your Project

To maximize the quality of Pine Nut Shell Biochar, align your equipment usage with your specific material goals:

- If your primary focus is electrical conductivity: Ensure the furnace maintains a deep, consistent vacuum throughout the entire 400°C cycle to prevent any oxidative degradation.

- If your primary focus is surface chemistry: Monitor the temperature regulation strictly, as the 400°C setpoint is calibrated to generate specific functional groups without destroying the carbon skeleton.

Precision in the vacuum environment is the difference between creating high-grade anode material and common charcoal.

Summary Table:

| Feature | Function in PBC Preparation | Impact on Material Quality |

|---|---|---|

| Vacuum Environment | Prevents combustion and oxidation | Preserves high specific surface area and conductivity |

| Temperature Control | Maintains stable 400°C thermal decomposition | Ensures optimal pore development and functional groups |

| Oxidation Shielding | Removes oxygen from the chamber | Prevents biochar from turning into ash |

| Pyrolysis Execution | Breaks down organic chemical bonds | Facilitates the transition from biomass to carbon-rich solid |

Elevate Your Material Research with KINTEK

Precision in vacuum carbonization is the difference between ordinary charcoal and high-grade anode materials. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, and CVD systems—all fully customizable to meet your specific research needs.

Whether you are developing PBC biochar or advanced electronic substrates, our furnaces provide the oxygen-free environment and thermal stability required for superior conductivity and surface chemistry.

Ready to optimize your carbonization process? Contact KINTEK today to find the perfect lab high-temp furnace for your project!

Visual Guide

References

- Chun Zhao, Shaojun Zhang. TiO₂/g-C₃N₄@HPBC Photoanode in PMFC for Shipboard Oily Wastewater Degradation. DOI: 10.54691/kk8pft70

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is application important when selecting a muffle furnace? Ensure Optimal Performance for Your Lab

- How do crucible furnaces provide cost-effectiveness? Balancing Low Upfront Cost with Operational Efficiency

- What are the main structural components of a muffle furnace? Discover the Engineered System for Contamination-Free Heating

- Why Use a Programmable Muffle Furnace for Perovskite Calcination? Achieve 1100°C Phase Purity

- How does a high-precision furnace enhance EIS testing for niobium-doped titanium dioxide? Achieve Accurate Material Data

- Why is a high-temperature box resistance furnace essential for failure analysis? Master TGO Growth and Isothermal Testing

- What materials are prohibited from being placed in a high-temperature muffle furnace? Ensure Safety and Protect Your Equipment

- What should be considered when choosing a muffle furnace manufacturer? Key Factors for Optimal Lab Performance