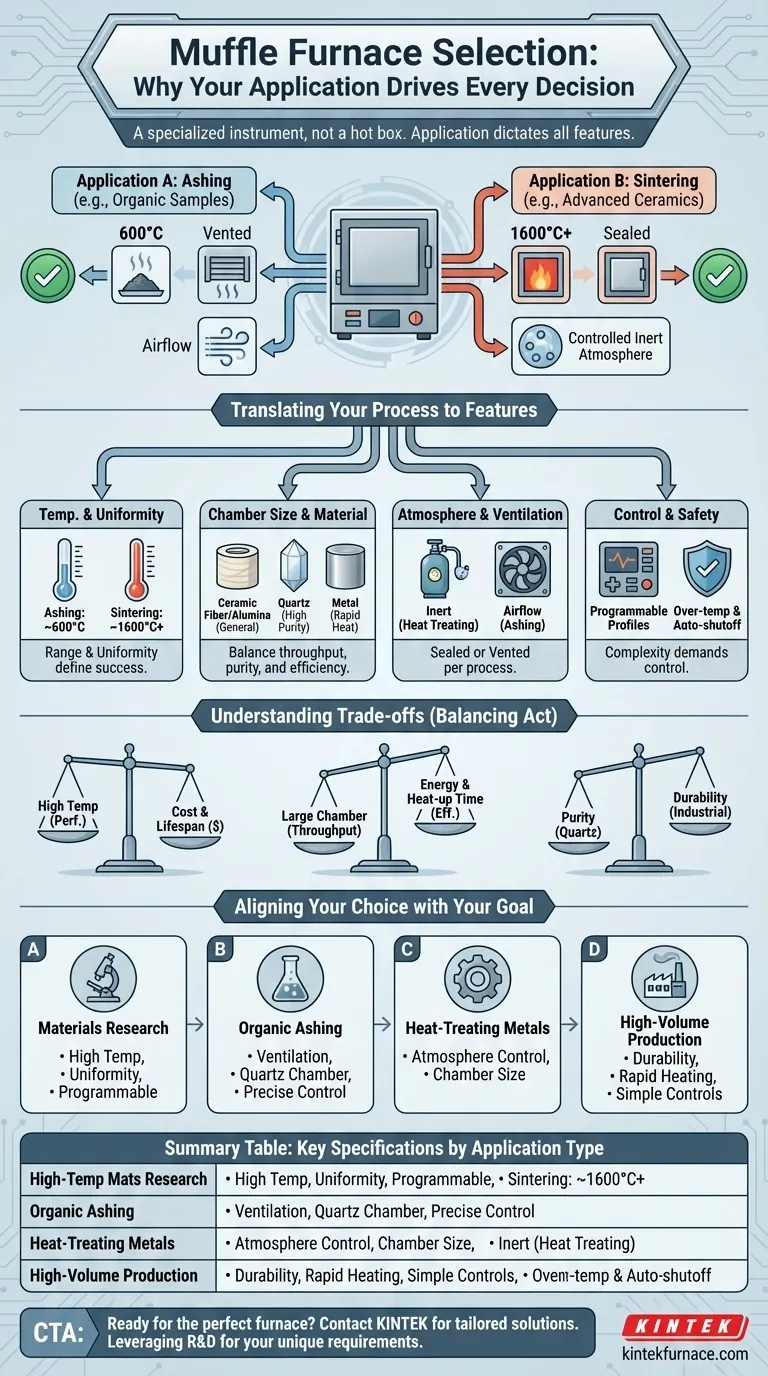

Selecting a muffle furnace based on your specific application is paramount because the application dictates every critical design feature, from the maximum temperature it can safely reach to the materials used in its construction. A furnace optimized for ashing organic samples is fundamentally different from one designed for sintering advanced ceramics. Choosing incorrectly can result in failed processes, damaged samples, or a significant waste of resources.

A muffle furnace is not a commodity; it is a specialized instrument. The central takeaway is that you are not just buying a "hot box." You are selecting a tool engineered for a specific task, and defining that task—your application—is the only way to determine the correct specifications for temperature, chamber, atmosphere, and control.

Translating Your Application into Specifications

Your specific process—be it heat treating, ashing, or alloying—creates a unique set of technical demands. Understanding how your application translates into furnace features is the key to making a sound investment.

Maximum Temperature and Heat Distribution

The single most important factor is the required temperature range. Different applications operate at vastly different thermal levels.

A furnace for ashing biological samples may only need to reach 600°C. In contrast, one for sintering zirconia ceramics might need to sustain temperatures of 1600°C or higher.

Beyond the maximum temperature, consider heat uniformity. For applications like materials research or producing certified reference materials, every sample in the chamber must experience the exact same temperature. This requires furnaces with superior insulation and strategically placed heating elements.

Chamber Size and Material

The chamber must be appropriately sized for your workload. A chamber that is too large for small samples wastes energy and takes longer to heat up. A chamber that is too small limits your throughput.

The chamber's material is equally crucial and depends entirely on your process.

- Ceramic Fiber/Alumina: These are excellent insulators, common in general-purpose and high-temperature furnaces for applications like heat treatment and material research.

- Quartz: A quartz chamber offers superior corrosion resistance. This makes it ideal for processes involving corrosive chemicals or where sample purity is absolutely critical.

- Metal: Metal-lined chambers provide excellent thermal conductivity for rapid heating, making them well-suited for high-throughput production environments.

Atmosphere and Ventilation

Many applications are sensitive to the atmosphere inside the furnace. You must determine if your process needs to be isolated from air or, conversely, requires a steady supply of it.

Heat treating many metals or brazing requires an inert atmosphere (like argon or nitrogen) to prevent oxidation. Furnaces for these tasks must have sealed chambers and ports for introducing inert gas.

In contrast, ashing is a combustion process that requires a constant flow of air or oxygen. A furnace for ashing must have an effective air intake and a vent or chimney to safely exhaust smoke and fumes.

Control, Programming, and Safety

The level of control you need is dictated by the complexity and sensitivity of your application.

Simple, repetitive tasks may only require a basic controller that holds a single temperature. However, research, pharmaceutical development, or complex multi-stage heat treatments demand a programmable controller. This allows you to create profiles with different ramp rates, dwell times, and cooling rates.

Safety features like over-temperature protection and automatic shut-off are non-negotiable. They protect your samples, the furnace, and your facility from catastrophic failure.

Understanding the Trade-offs

Selecting a furnace always involves balancing performance, cost, and longevity. There is no single "best" furnace, only the best one for a specific job.

High Temperature vs. Cost and Lifespan

Furnaces capable of reaching extremely high temperatures (1700°C+) are significantly more expensive. They require premium insulation and specialized heating elements (like molybdenum disilicide) that have a finite lifespan and are costly to replace.

Chamber Size vs. Energy and Heat-up Time

A larger chamber provides higher throughput but consumes more power and takes much longer to reach the target temperature. For frequent work with small samples, a smaller, more responsive furnace is a more efficient choice.

Process Purity vs. Durability

While a quartz chamber offers the highest purity and corrosion resistance, it is more fragile and expensive than a standard ceramic fiber chamber. You must weigh the absolute need for a non-reactive environment against the demands of a high-use industrial setting.

Making the Right Choice for Your Goal

To ensure your furnace is an asset rather than a liability, align your choice with your primary objective.

- If your primary focus is high-temperature materials research: Prioritize the maximum temperature, heat uniformity, and a programmable controller for complex thermal cycles.

- If your primary focus is organic sample ashing: Prioritize excellent ventilation, a corrosion-resistant chamber, and precise low-to-mid range temperature control.

- If your primary focus is heat-treating metals: Prioritize the ability to control the atmosphere (e.g., inert gas ports) and a chamber size that matches your typical part dimensions.

- If your primary focus is high-volume production: Prioritize durability, rapid heating/cooling rates, and simple, repeatable controls to ensure process consistency.

Defining your application first transforms the complex task of selecting a furnace into a logical and methodical process.

Summary Table:

| Application Type | Key Specifications |

|---|---|

| High-Temperature Materials Research | Max temp up to 1700°C+, heat uniformity, programmable controller |

| Organic Sample Ashing | Ventilation, corrosion-resistant chamber (e.g., quartz), precise low-mid temp control |

| Heat-Treating Metals | Atmosphere control (inert gas), chamber size for parts |

| High-Volume Production | Durability, rapid heating/cooling, simple controls |

Ready to find the perfect muffle furnace for your application? At KINTEK, we specialize in high-temperature furnace solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental requirements, enhancing efficiency and reliability. Don't settle for a one-size-fits-all solution—contact us today to discuss how we can support your lab's success!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis