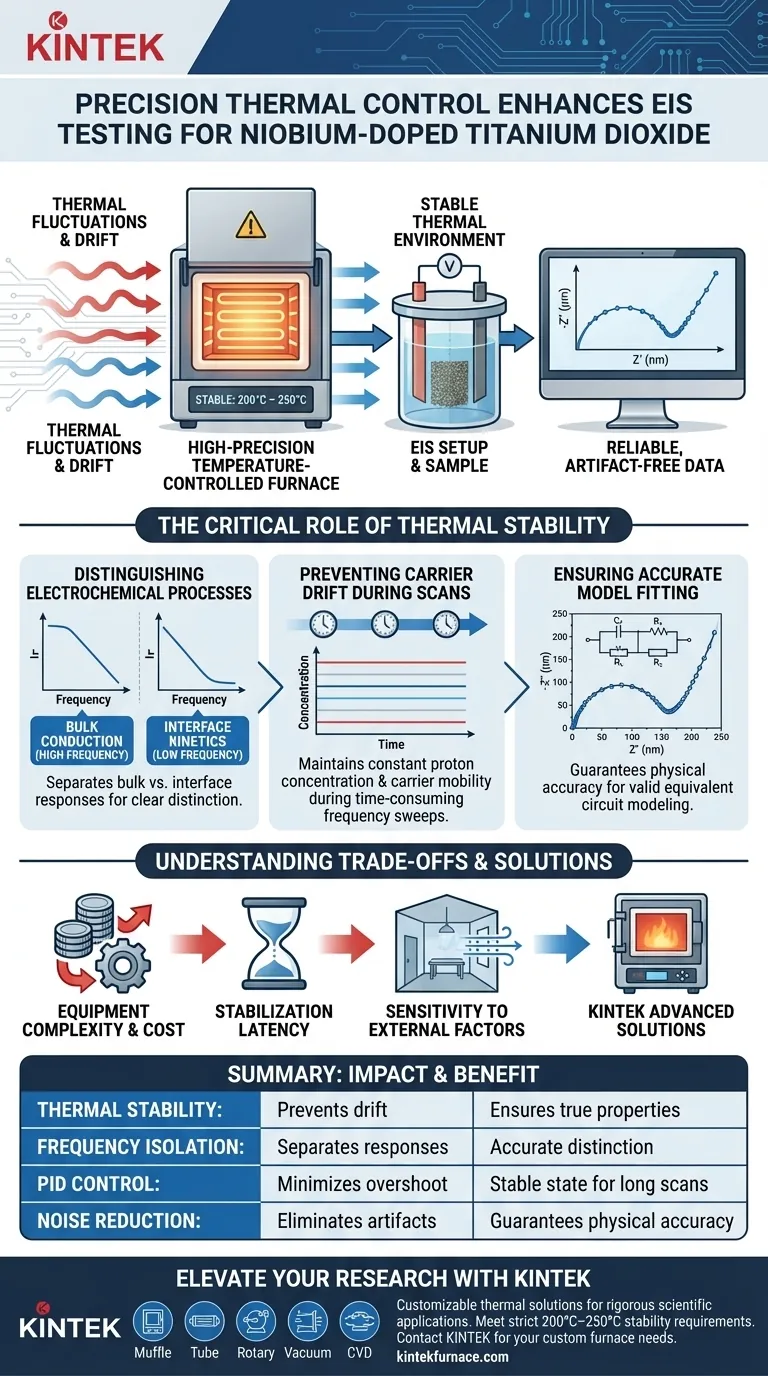

A high-precision temperature-controlled furnace enhances Electrochemical Impedance Spectroscopy (EIS) by maintaining a strictly stable thermal environment, particularly within the critical 200°C to 250°C operating window. This stability is the deciding factor in preventing the drift of proton concentration and carrier mobility during time-consuming frequency scans. By eliminating thermal noise, the furnace ensures that the resulting data reflects the true material properties of the niobium-doped titanium dioxide rather than environmental fluctuations.

Reliable EIS analysis depends on the isolation of specific electrochemical mechanisms. Without precise temperature control, thermal drift blurs the distinction between bulk conduction and interface reactions, rendering equivalent circuit models physically inaccurate.

The Critical Role of Thermal Stability

Distinguishing Electrochemical Processes

In niobium-doped titanium dioxide, different electrochemical behaviors occur at different frequencies. High-frequency responses typically represent bulk properties, such as proton conduction resistance. Conversely, low-frequency responses usually correspond to interface phenomena, like charge transfer impedance.

A high-precision furnace ensures these responses remain distinct. If the temperature fluctuates, the spectral features of these processes can overlap or shift. This stability allows you to clearly separate the bulk material performance from surface interface interactions.

Preventing Carrier Drift During Scans

EIS frequency scans are not instantaneous; they require time to sweep from high to low frequencies. During this period, the internal state of the material must remain constant.

Temperature fluctuations cause immediate changes in proton concentration and carrier mobility within the doped oxide. If these variables change during the scan, the data becomes skewed. Precise thermal regulation "freezes" the thermodynamic state of the material, ensuring the first data point and the last data point represent the same physical environment.

Ensuring Accurate Model Fitting

The end goal of EIS is often to fit the raw data to an equivalent circuit model. This model provides the quantitative values for resistance, capacitance, and inductance in the system.

If the temperature drifts, the data will contain artifacts that do not fit standard physical models. A high-precision furnace guarantees the physical accuracy of the data, allowing for a valid fit that truly represents the microstructure and electrochemical behavior of the niobium-doped titanium dioxide.

Understanding the Trade-offs

Equipment Complexity and Cost

Achieving high precision, especially at the specific 200°C to 250°C range, requires advanced heating elements and controllers. This increases the initial capital investment and the complexity of the experimental setup compared to standard laboratory ovens.

Stabilization Latency

High-precision furnaces often utilize complex PID (Proportional-Integral-Derivative) control loops to minimize overshoot. This can result in longer wait times for the system to reach and fully stabilize at the setpoint temperature before testing can begin.

Sensitivity to External Factors

Because these furnaces are designed for high sensitivity, they can be more susceptible to ambient room temperature changes or airflow drafts if not properly insulated. Rigorous calibration and isolation are often required to maintain the promised precision.

Making the Right Choice for Your Goal

How to Apply This to Your Project

To maximize the value of your EIS testing, match your thermal control strategy to your specific analytical needs.

- If your primary focus is Bulk Proton Conduction: Prioritize stability to ensure high-frequency resistance values are not skewed by rapid thermal changes.

- If your primary focus is Interface Kinetics: Ensure the furnace holds temperature precisely over long durations to capture slow, low-frequency charge transfer processes without drift.

Precision in temperature control is not just an operational detail; it is the baseline requirement for valid electrochemical data in advanced materials.

Summary Table:

| Feature | Impact on EIS Testing | Benefit for Niobium-Doped TiO2 |

|---|---|---|

| Thermal Stability | Prevents drift in proton concentration | Ensures data reflects true material properties |

| Frequency Isolation | Separates bulk vs. interface responses | Accurate distinction between conduction and kinetics |

| PID Control | Minimizes temperature overshoot | Provides a stable thermodynamic state for long scans |

| Noise Reduction | Eliminates thermal artifacts | Guarantees physical accuracy for circuit model fitting |

Elevate Your Electrochemical Research with KINTEK

Precise data starts with a stable environment. KINTEK provides high-performance thermal solutions specifically designed for rigorous scientific applications. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to meet the strict 200°C–250°C stability requirements of your EIS testing.

Whether you are analyzing proton conduction or interface kinetics in advanced oxides, our lab high-temp furnaces ensure your materials are tested under perfect conditions. Contact KINTEK today to discuss your custom furnace needs and secure the precision your research deserves.

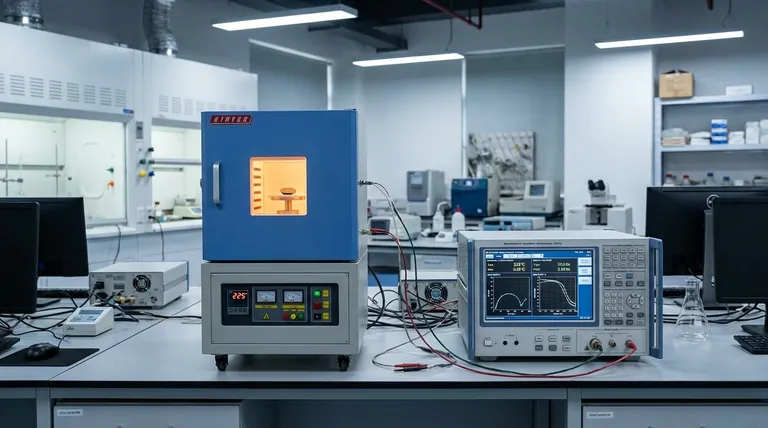

Visual Guide

References

- Tomoyuki Shiraiwa, Takahisa Omata. Enhanced Proton Transport in Nb-Doped Rutile TiO<sub>2</sub>: A Highly Useful Class of Proton-Conducting Mixed Ionic Electronic Conductors. DOI: 10.1021/jacs.5c05805

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a high-temperature muffle furnace play in g-C3N4 catalyst synthesis? Precision Pyrolysis Solutions

- Why is a high-temperature muffle furnace required for U3O8 preparation? Achieving Phase Purity and Stability

- What functions does a laboratory muffle furnace perform during composite film fabrication? Expert Guide

- What type of temperature control does the basic muffle furnace have? Discover Simple, Accurate Heating Solutions

- How does a muffle furnace facilitate the direct thermal polymerization of melamine? Master g-C3N4 Synthesis Today

- What is the significance of high-temperature furnace equipment in electrode testing? Ensure Industrial Peak Performance

- What is the function of a muffle furnace during Cu–Ce/HZSM-5 production? Optimize Calcination & Regeneration Stages

- What are the critical functions of a muffle furnace in perovskite synthesis? Master High-Purity Precursor Production