At its core, a basic muffle furnace uses a simple automatic digital controller. This type of controller is designed to heat the furnace to a single, user-defined temperature and hold it there accurately. While modern furnaces offer complex programming, the fundamental control system on a basic model is built for straightforward, single-temperature applications.

The term "muffle furnace" can describe anything from a simple kiln to a sophisticated laboratory instrument. The critical distinction lies not in its ability to get hot, but in the sophistication of its temperature controller—specifically, whether it can only hold one temperature or execute a multi-step heating and cooling program.

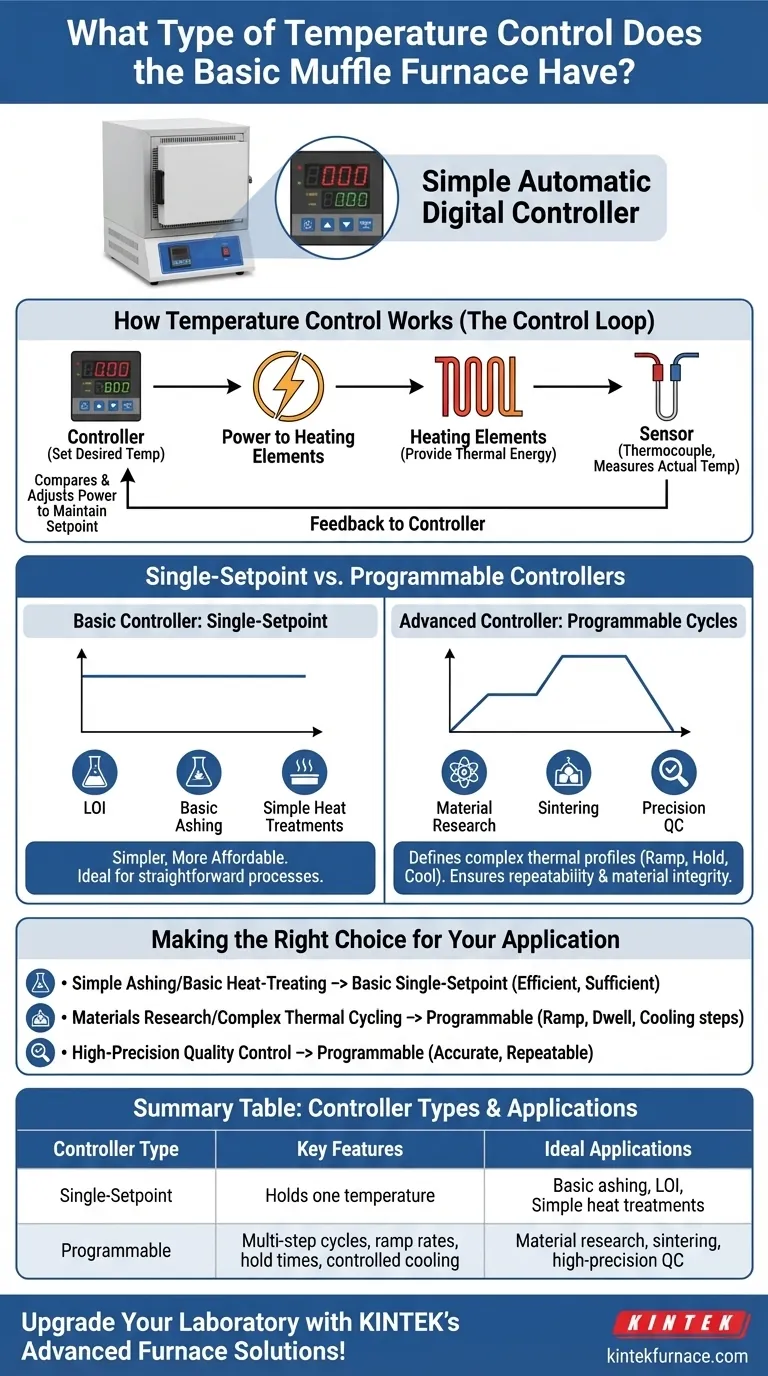

How Temperature Control Works

A muffle furnace's ability to maintain a precise temperature relies on a coordinated system of components working in a continuous feedback loop. Understanding this system is key to understanding the furnace's capabilities.

The Core Components

The temperature control system consists of three main parts. The temperature controller is the brain, where you set the desired temperature. A sensor, typically a thermocouple, acts as the nerve ending, constantly measuring the actual temperature inside the chamber. Finally, the heating elements provide the thermal energy.

The Control Loop Explained

When you set a temperature, the controller sends power to the heating elements. The thermocouple feeds the current chamber temperature back to the controller. The controller continuously compares the actual temperature to your setpoint and adjusts the power to the heating elements to minimize the difference, holding the temperature steady.

Single-Setpoint vs. Programmable Controllers

The type of controller is the single biggest factor determining what you can achieve with a muffle furnace. The difference between a basic and an advanced model comes down to this component.

The Basic Controller: Single Setpoint

A basic furnace is equipped with a single-setpoint controller. You set one target temperature, and the furnace heats to that point and maintains it. This is ideal for simple, direct processes like determining loss-on-ignition (LOI), basic ashing, or simple heat treatments where the rate of heating is not critical.

The Advanced Controller: Programmable Cycles

More advanced furnaces feature programmable controllers. These allow you to define complex, multi-step thermal profiles. You can set specific ramp-up rates (how fast to heat), hold times (how long to stay at a temperature), and controlled cooling periods. This precision is vital for material research, sintering, and any process where the thermal journey is as important as the final temperature.

Understanding the Trade-offs

Choosing a furnace requires balancing its capabilities against your specific needs and budget. The controller is often the central point of this decision.

Simplicity and Cost

A basic, single-setpoint furnace is simpler to operate and significantly more affordable. If your tasks do not require complex heating schedules, this is the most direct and cost-effective solution.

Process Repeatability

For research, quality control, or any application where results must be highly reproducible, a programmable controller is superior. It eliminates the human variable in heating and cooling rates, ensuring every cycle runs exactly the same way.

Material Integrity

Certain materials can be damaged by thermal shock if heated or cooled too quickly. A programmable controller allows you to manage these rates precisely, protecting your samples and ensuring the integrity of the final product.

Making the Right Choice for Your Application

The right furnace is the one that meets your technical requirements without adding unnecessary complexity or cost.

- If your primary focus is simple ashing or basic heat-treating: A furnace with a basic, single-setpoint digital controller is efficient and sufficient.

- If your primary focus is materials research or complex thermal cycling: A programmable controller is non-negotiable for defining ramp, dwell, and cooling steps.

- If your primary focus is high-precision quality control: A modern, programmable controller is essential to guarantee the process is accurate and repeatable every time.

Ultimately, understanding the type of temperature control is the key to matching the furnace's capability to your scientific or industrial goal.

Summary Table:

| Controller Type | Key Features | Ideal Applications |

|---|---|---|

| Single-Setpoint | Simple automatic digital control, holds one temperature | Basic ashing, loss-on-ignition (LOI), simple heat treatments |

| Programmable | Multi-step cycles, ramp rates, hold times, controlled cooling | Material research, sintering, high-precision quality control |

Upgrade Your Laboratory with KINTEK's Advanced Furnace Solutions!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you need a basic single-setpoint controller for simple tasks or a programmable system for complex thermal cycling, we deliver reliable, precise, and cost-effective equipment to enhance your process efficiency and repeatability. Don't let temperature control limitations hold back your research—contact us today to discuss your needs and discover how KINTEK can power your innovations!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control