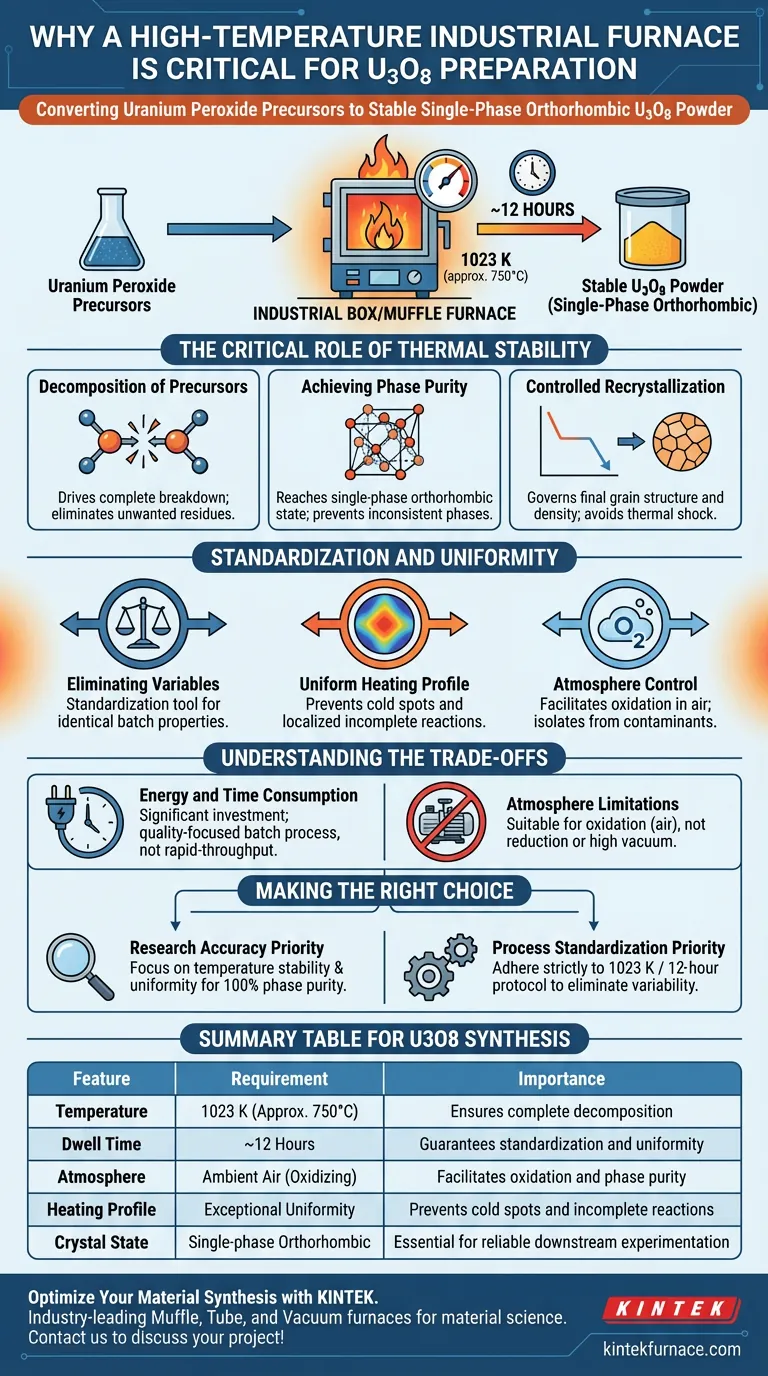

To ensure the integrity of your starting material, a high-temperature industrial box furnace is the critical tool required to convert uranium peroxide precursors into stable U3O8 powder. Specifically, this equipment provides the strictly controlled environment needed to heat the material to 1023 K (approximately 750°C) in air for extended periods, usually around 12 hours.

The core function of these furnaces is to facilitate complete thermal decomposition and recrystallization, ensuring the production of a standardized, single-phase raw material essential for reliable downstream experimentation.

The Critical Role of Thermal Stability

Decomposition of Precursors

The primary task of the furnace is to drive the decomposition of uranium peroxide. This process requires sustained high temperatures to break down the chemical bonds of the precursor effectively. Without the consistent heat provided by a muffle or box furnace, the decomposition may remain incomplete, leaving unwanted residues.

Achieving Phase Purity

To create high-quality U3O8, the material must reach a specific crystallographic state: single-phase orthorhombic U3O8. Heating the material to 1023 K ensures that the powder achieves this precise phase. Inconsistent temperatures would result in a mixture of phases, rendering the material unsuitable for high-precision applications.

Controlled Recrystallization

Beyond simple heating, these furnaces allow for controlled cooling rates. This control is vital for the recrystallization process, governing the final grain structure and density of the powder. A box furnace creates a static, protected environment where these slow structural changes can occur without thermal shock.

Standardization and Uniformity

Eliminating Variables

For scientific reduction experiments, the starting material must be a "known quantity." The industrial box furnace acts as a standardization tool. By subjecting the material to a rigorous 12-hour heat treatment, it ensures every batch of U3O8 has identical properties.

Uniform Heating Profile

Muffle furnaces are designed to provide exceptionally uniform heating across the entire chamber. This eliminates "cold spots" that could lead to localized incomplete reactions. Uniformity is essential to prevent impurity residues that might diffuse poorly during subsequent processing.

Atmosphere Control

This specific synthesis requires heating in an air atmosphere to facilitate oxidation. Industrial box furnaces naturally support this environment while isolating the sample from direct contact with heating elements or fuel contaminants. This prevents the introduction of external impurities during the long calcination cycle.

Understanding the Trade-offs

Energy and Time Consumption

The requirement for a 12-hour cycle at 1023 K represents a significant energy investment and processing bottleneck. This is not a rapid-throughput method; it is a quality-focused batch process. Attempting to shorten this cycle to save time can compromise the phase purity of the final oxide.

Atmosphere Limitations

While excellent for oxidation processes like creating U3O8, standard box furnaces operating in air are not suitable for processes requiring reduction or high vacuum. If your workflow shifts to requiring oxygen-free environments (such as in semiconductor doping or specific alloy annealing), a standard air-atmosphere muffle furnace will no longer suffice.

Making the Right Choice for Your Goal

When selecting or operating a furnace for U3O8 preparation, prioritize the specific needs of your experimental baseline.

- If your primary focus is Research Accuracy: Prioritize temperature stability and uniformity over heating speed to ensure the production of 100% single-phase orthorhombic powder.

- If your primary focus is Process Standardization: Establish and strictly adhere to the 1023 K / 12-hour protocol to eliminate raw material variability as a potential cause of failure in subsequent experiments.

Reliable U3O8 synthesis is not just about reaching a temperature; it is about maintaining a precise thermal history to guarantee chemical and structural uniformity.

Summary Table:

| Feature | Requirement for U3O8 Synthesis | Importance |

|---|---|---|

| Temperature | 1023 K (Approx. 750°C) | Ensures complete decomposition of precursors |

| Dwell Time | ~12 Hours | Guarantees standardization and grain uniformity |

| Atmosphere | Ambient Air (Oxidizing) | Facilitates necessary oxidation and phase purity |

| Heating Profile | Exceptional Uniformity | Prevents cold spots and localized incomplete reactions |

| Crystal State | Single-phase Orthorhombic | Essential for reliable downstream experimentation |

Optimize Your Material Synthesis with KINTEK

Precise thermal history is the key to reliable U3O8 raw material production. KINTEK provides industry-leading Muffle, Tube, and Vacuum furnaces engineered for the rigorous demands of material science. Backed by expert R&D and manufacturing, our systems ensure the temperature stability and uniformity required to eliminate variables in your research.

Whether you need standard box furnaces or fully customizable high-temp systems tailored to your unique lab specifications, KINTEK delivers the accuracy your experiments deserve.

Ready to upgrade your lab's thermal processing?

Contact KINTEK today to discuss your project requirements!

Visual Guide

References

- <i>In Situ</i> X‐ray Diffraction Studies on the Reduction of U <sub>3</sub> O <sub>8</sub> by Various Reducing Agents. DOI: 10.1002/chem.202500978

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is temperature control important during the initial baking of a muffle furnace? Prevent Permanent Damage and Ensure Longevity

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- How are muffle furnaces applied in the glass industry? Unlock Precision in Glass Processing

- What specific function does a Muffle Furnace perform in determining the moisture content of Safou pulp? Essential Guide

- How does the heating process work in a muffle furnace? Discover Clean, Uniform Heating for Your Lab

- Why is input voltage an important factor in selecting a muffle furnace? Ensure Safety and Performance for Your Lab

- What is the primary purpose of a box furnace? Achieve Precise Heat Treatment for Your Materials

- What is the role of a muffle furnace in the preparation of bulk graphitic carbon nitride (BCN)? Master BCN Synthesis