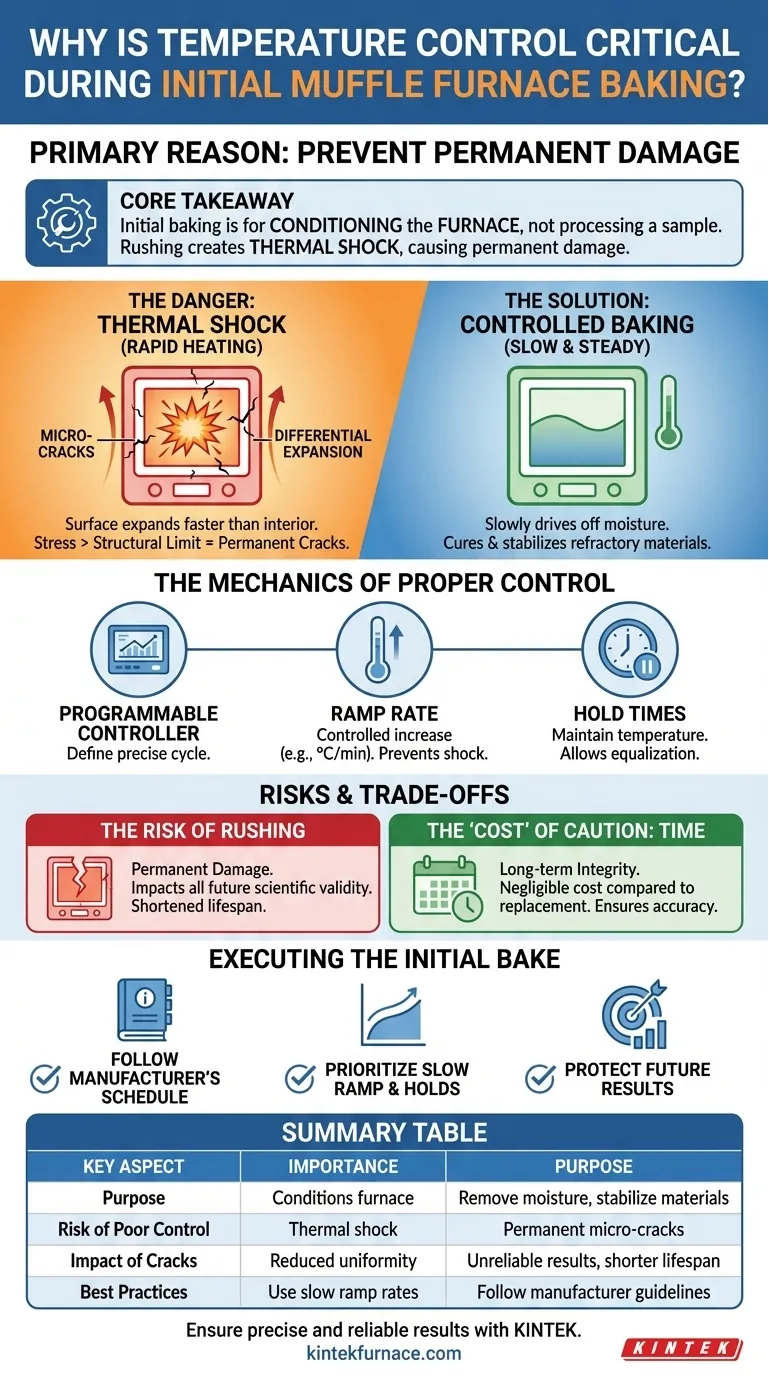

The primary reason is to prevent permanent damage. Proper temperature control during the initial "baking" or "burn-in" of a new muffle furnace is critical to prevent the formation of numerous small cracks in the furnace's internal refractory materials, which can occur from excessive or rapid heating.

The core takeaway is that the initial baking cycle is not for processing a sample; it is a one-time conditioning process for the furnace itself. Rushing this step through rapid heating creates thermal shock, which physically damages the furnace and compromises its performance for its entire lifespan.

Why Initial Baking Is a Critical Process

The first time you heat a muffle furnace is the most delicate operation in its life. This initial cycle isn't about your experiment; it's about preparing the equipment for a long and reliable service life.

The Purpose of a "Burn-In" Cycle

A new muffle furnace contains refractory ceramic insulation that may hold residual moisture or binders from the manufacturing process.

The initial baking cycle is designed to slowly and gently drive off this moisture and cure the ceramic materials, allowing them to settle and stabilize.

The Danger of Thermal Shock

Refractory materials expand when heated. If the temperature rises too quickly, the surface of the material will expand much faster than its interior.

This differential expansion creates immense internal stress. When this stress exceeds the material's structural limit, it results in micro-cracks.

How Cracks Compromise Future Performance

These cracks, once formed, are permanent. They degrade the furnace's performance in several key ways.

First, they compromise the furnace's ability to maintain temperature uniformity, leading to inconsistent heating of your samples and unreliable experimental results. Second, they can shorten the lifespan of the heating elements and the furnace chamber itself.

The Mechanics of Proper Temperature Control

Modern furnaces provide the tools to execute this process with high precision. Understanding these tools is key to preventing damage.

The Role of the Programmable Controller

Most modern furnaces use a digital temperature controller. This device allows you to program a precise heating cycle.

You can define not just the target temperature, but the exact rate of temperature increase (ramp rate) and the duration it stays at specific temperatures (hold time).

Defining the Ramp Rate

The ramp rate is the speed at which the furnace temperature increases, often measured in degrees per minute or hour.

For an initial bake, the manufacturer will specify a very slow ramp rate to ensure the entire refractory body heats up evenly, preventing the thermal stress that causes cracking.

The Importance of Hold Times

A programmed hold time forces the furnace to maintain a set temperature for a specific period.

During initial baking, these holds are used at intermediate temperatures to allow moisture to fully escape and to give the material time to thermally equalize before ramping up further.

Understanding the Risks and Trade-offs

Properly baking a furnace is a test of patience. The primary trade-off is investing time upfront to guarantee long-term asset integrity.

The Risk of Rushing: Permanent Damage

The most significant risk is trying to save time. Heating the furnace to its maximum temperature on its first use without a slow, controlled ramp is the surest way to cause damage.

This damage is not cosmetic; it directly impacts the scientific validity of all future work done in that furnace.

The "Cost" of Caution: Time

A proper initial baking cycle can take many hours, sometimes even more than a day, depending on the furnace's size and materials.

This investment of time is non-negotiable and negligible compared to the cost of replacing a damaged furnace or retracting flawed experimental data.

Baking vs. Operational Heating

It is critical to distinguish between the initial burn-in and normal operational use.

Once a furnace is properly baked, it can typically be heated to its operational temperature much more quickly because the materials have already been stabilized. The goal shifts from conditioning the furnace to processing the sample.

Executing the Initial Bake Correctly

Your approach to the first use of a muffle furnace sets the stage for its entire operational life. Following protocol is the only way to ensure success.

- If you have a new furnace: Your first action must be to locate and strictly follow the manufacturer's specified initial baking schedule.

- If you are programming the cycle: Prioritize a slow, gradual ramp rate and adhere to all specified hold times to prevent thermal shock.

- If you are concerned about future results: Understand that this initial step directly impacts the temperature uniformity and reproducibility of all subsequent experiments.

Protecting your equipment through a careful and methodical initial bake is the first step toward achieving accurate and repeatable results.

Summary Table:

| Key Aspect | Importance in Initial Baking |

|---|---|

| Purpose | Conditions furnace by removing moisture and stabilizing materials |

| Risk of Poor Control | Thermal shock leading to permanent micro-cracks |

| Impact of Cracks | Reduced temperature uniformity, shorter lifespan, unreliable results |

| Best Practices | Use slow ramp rates and hold times as per manufacturer guidelines |

Ensure your muffle furnace delivers precise and reliable results from day one. At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to tailor solutions to your unique experimental needs, ensuring optimal performance and longevity. Contact us today to discuss how we can enhance your laboratory's efficiency and accuracy!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization