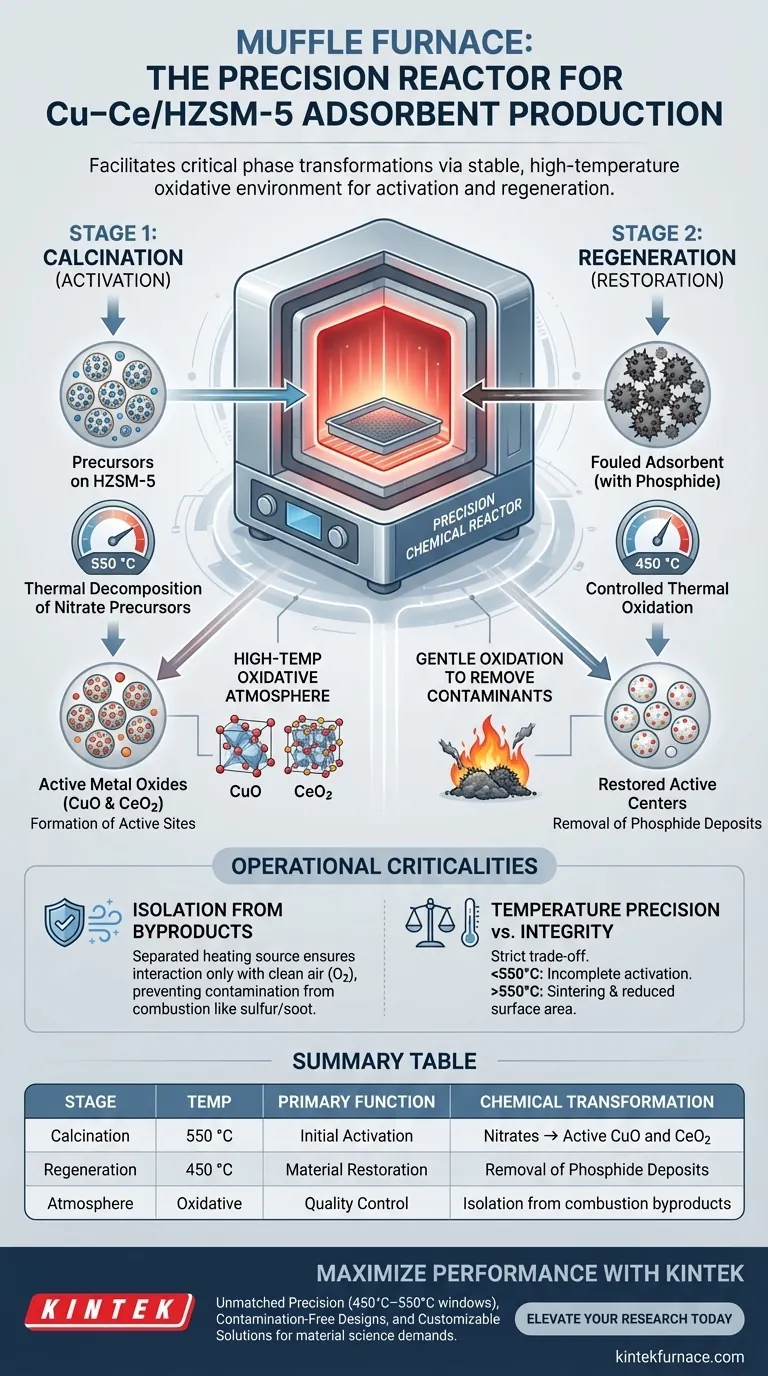

The primary function of a muffle furnace in the production of Cu–Ce/HZSM-5 adsorbents is to facilitate critical phase transformations through a stable, high-temperature oxidative environment. Specifically, it is responsible for converting precursor chemicals into active metal oxides during the initial calcination and stripping away surface contaminants to restore functionality during the regeneration phase.

Core Takeaway The muffle furnace acts as a precision chemical reactor that uses heat to drive specific oxidation reactions. Its role is twofold: it activates the adsorbent by turning nitrate precursors into essential copper and cerium oxides (CuO and CeO2), and it extends the material's lifespan by burning off phosphide deposits that poison the active sites.

The Calcination Stage: Activation

The first critical application of the muffle furnace occurs immediately after the metal precursors have been impregnated onto the HZSM-5 support.

Thermal Decomposition of Precursors

During the preparation of the adsorbent, copper and cerium are typically introduced as nitrate salts.

The muffle furnace provides a consistent thermal environment at 550 °C. At this specific temperature, the furnace drives the complete thermal decomposition of these nitrate precursors.

Formation of Active Metal Oxides

The goal of calcination is not just drying; it is a chemical transformation.

The high-temperature oxidative atmosphere converts the decomposed nitrates into stable metal oxides, specifically copper oxide (CuO) and cerium oxide (CeO2). These oxides constitute the active "sites" of the adsorbent that are capable of performing chemical separations.

The Regeneration Stage: Restoration

Adsorbents eventually lose efficiency as their surface becomes fouled with contaminants. The muffle furnace is utilized here to reverse this deactivation.

Removal of Phosphide Deposits

During operation, the Cu–Ce/HZSM-5 adsorbent may accumulate phosphide deposits.

These deposits block the active centers, rendering the material ineffective. The muffle furnace removes these contaminants through thermal oxidation.

Controlled Thermal Oxidation

Regeneration requires a delicate balance between cleaning the material and preserving its structure.

The furnace is set to a lower temperature of 450 °C for this stage. This temperature is sufficient to oxidize and remove the phosphide deposits, restoring the activity centers without subjecting the material to the higher thermal stress used during the initial calcination.

Understanding Operational Criticalities

While the concept of heating is simple, the method of heating provided by a muffle furnace is distinct and critical for material quality.

Isolation from Combustion Byproducts

A defining feature of a muffle furnace is the separation of the heating source from the heating chamber.

This isolation ensures that the Cu–Ce/HZSM-5 material interacts only with air (oxygen) and heat, rather than being contaminated by combustion byproducts (like sulfur or carbon soot) that might occur in a direct-flame furnace.

Temperature Precision vs. Material Integrity

There is a strict trade-off between complete activation and structural damage.

If the calcination temperature drops significantly below 550 °C, the nitrate precursors may not fully decompose, resulting in low activity. Conversely, excessive temperatures can cause sintering, where the dispersed metal oxide particles clump together, reducing the specific surface area and overall efficiency.

Making the Right Choice for Your Goal

To ensure the highest quality Cu–Ce/HZSM-5 adsorbent, you must tailor the thermal treatment to the specific lifecycle stage of the material.

- If your primary focus is Initial Production: Ensure the furnace maintains a stable 550 °C to guarantee the complete conversion of nitrates into active CuO and CeO2 species.

- If your primary focus is Material Longevity: Set the furnace to 450 °C to gently oxidize phosphide contaminants, restoring activity without thermally degrading the zeolite structure.

Precise thermal control is not merely a manufacturing step; it is the mechanism that defines the chemical identity and lifespan of your adsorbent.

Summary Table:

| Stage | Temperature | Primary Function | Chemical Transformation |

|---|---|---|---|

| Calcination | 550 °C | Initial Activation | Nitrates → Active CuO and CeO2 |

| Regeneration | 450 °C | Material Restoration | Removal of Phosphide Deposits |

| Atmosphere | Oxidative | Quality Control | Isolation from combustion byproducts |

Maximize Your Adsorbent Performance with KINTEK

Precise thermal control is the difference between a high-efficiency adsorbent and a failed reaction. KINTEK provides industry-leading muffle, tube, and vacuum furnace systems designed to meet the rigorous demands of material science.

Why choose KINTEK?

- Unmatched Precision: Maintain the exact 450°C–550°C windows required for Cu–Ce/HZSM-5 stability.

- Contamination-Free: Our advanced muffle designs isolate your materials from all combustion byproducts.

- Customizable Solutions: Backed by expert R&D, we offer fully customizable high-temp systems tailored to your unique lab specifications.

Ready to elevate your research and production quality? Contact our technical experts today to find your perfect furnace solution!

Visual Guide

References

- Zhiyuan Liu, Guoqiang Huang. Acid-modified Cu–Ce/HZSM-5 adsorbent removes trace phosphorus impurities from recycled hydrogen during polysilicon production. DOI: 10.1039/d5ra01322d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the applications of muffle furnaces in the battery manufacturing and research industry? Unlock Precision for Battery Innovation

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What are the critical functions of a muffle furnace in perovskite synthesis? Master High-Purity Precursor Production

- Why is high-temperature thermal treatment in a muffle furnace required for cobalt oxide nanoparticles? Guide to Co3O4

- What role does a laboratory muffle furnace play in the fluorination roasting stage of NdFeB waste recovery?

- What are the key technologies used in the muffle furnace for annealing silicon-based materials? Precision Control for Superior Results

- What are the controller-based classifications of muffle furnaces? Choose the Right Control for Your Lab

- What is a muffle furnace and why is it significant? Unlock Clean, Controlled Heat for Accurate Results