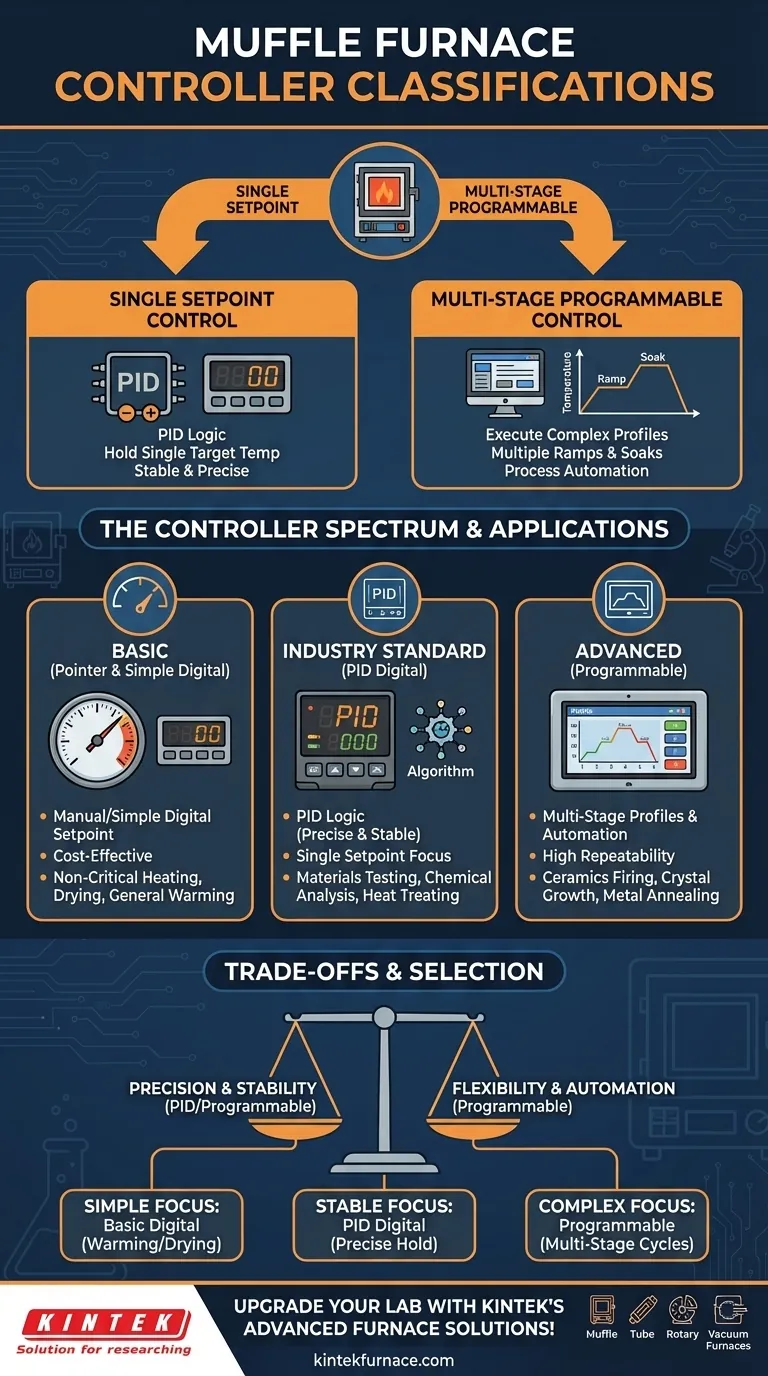

In essence, muffle furnaces are classified by their controllers into two primary categories: those with single setpoint control and those with multi-stage programmable control. The former uses a PID controller to hold a single target temperature, often with a simple digital display. The latter employs a more advanced computer-based controller that can execute complex heating profiles involving multiple temperatures, ramps, and soak times.

The choice of a furnace controller is not about which is "better," but which is appropriate for the task. Simple controllers are for static temperature applications, while programmable controllers are for processes that require precise thermal cycling over time.

Understanding the Core Controller Types

The controller is the brain of the muffle furnace, dictating its ability to reach and maintain specific temperatures. The classification spans from very basic manual systems to highly sophisticated automated ones.

The Foundational Tier: Pointer & Basic Digital Controllers

These represent the simplest form of temperature management.

- Pointer Controllers: These are older, analog systems. An operator manually sets a needle on a dial to the desired temperature. They are less precise and prone to overshoot but are simple and cost-effective for non-critical heating tasks.

- Simple Digital Display Controllers: An evolution from pointers, these allow an operator to digitally input a single temperature setpoint. While more readable, the underlying control mechanism may still be a basic on/off system, lacking the stability of more advanced controllers.

The Industry Standard: PID Digital Controllers

This is the most common and versatile type of controller found in modern laboratories and workshops.

- PID (Proportional-Integral-Derivative) Logic: This is an intelligent control loop algorithm that continuously calculates the difference between the setpoint and the actual furnace temperature. It then precisely adjusts the power output to minimize this error.

- Stable & Precise: Unlike a simple thermostat that just turns heating on or off, a PID controller modulates power to prevent overshooting the target temperature and maintains it with exceptional stability. This is crucial for materials testing, chemical analysis, and heat treating.

- Single Setpoint Focus: These controllers are designed to bring the furnace to one specific temperature and hold it there for as long as needed. The "SCR digital display" mentioned in technical literature refers to the hardware (Silicon-Controlled Rectifier) that executes the PID's commands.

The Advanced Tier: Programmable Controllers

When a process requires more than just holding one temperature, a programmable controller is necessary.

- Multi-Stage Profiles: These computer-based controllers allow users to program a sequence of steps. This profile can include multiple ramps (heating or cooling at a specific rate), soaks (holding at a temperature for a set time), and end steps.

- Process Automation: Programmable control is essential for complex applications like ceramics firing, crystal growth, or advanced metal annealing, where the thermal history of the material is critical to the outcome.

- Repeatability: Once a program is created and saved, it can be executed identically every time, ensuring consistent and repeatable results across multiple batches.

Understanding the Trade-offs: Precision vs. Flexibility

Choosing a controller involves balancing cost, ease of use, and the technical requirements of your process. There is no single best option, only the most appropriate one for your goal.

Cost and Complexity

As a rule, cost increases with capability. A basic pointer or digital setpoint controller is the most affordable. PID controllers represent a moderate investment, while fully programmable controllers are the most expensive due to their advanced hardware and software.

Precision and Stability

PID and programmable controllers offer vastly superior precision and temperature stability compared to basic pointer or on/off digital systems. For any application where temperature accuracy is critical, a PID-based system is the minimum requirement.

Flexibility and Automation

Flexibility is the key differentiator. A single setpoint PID controller is highly precise but completely inflexible; it can only do one thing. A programmable controller offers ultimate flexibility, allowing you to design and automate nearly any thermal process you can conceive.

Choosing the Right Controller for Your Application

Your choice should be dictated entirely by the thermal processes you need to perform.

- If your primary focus is simple, non-critical heating: A basic digital display furnace is cost-effective and sufficient for general warming or drying.

- If your primary focus is holding a single, stable temperature with high precision: A furnace with a standard PID digital controller is the clear and correct choice.

- If your primary focus is executing complex, multi-stage thermal cycles: A furnace with a programmable controller is the only option that will meet your needs.

Ultimately, understanding these controller types empowers you to select a furnace as a precise tool engineered for your specific scientific or industrial task.

Summary Table:

| Controller Type | Key Features | Best For Applications |

|---|---|---|

| Pointer & Basic Digital | Manual or simple digital setpoint, cost-effective | Non-critical heating, drying, general warming |

| PID Digital | Precise temperature control, stable hold, single setpoint | Materials testing, chemical analysis, heat treating |

| Programmable | Multi-stage profiles, automation, high repeatability | Ceramics firing, crystal growth, metal annealing |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precise control options, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental requirements are met with reliability and efficiency. Contact us today to discuss how our furnaces can enhance your thermal processes and drive better results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis