In the battery industry, precision is everything. A muffle furnace is a fundamental tool used to create, process, and test the advanced materials that power modern batteries. Its primary applications involve the high-temperature synthesis of electrode powders like cathode and anode materials, the critical drying of components before assembly, and the analytical testing of material stability and composition.

The performance, safety, and cost of a battery are directly tied to the atomic structure of its materials. A muffle furnace provides the controlled, high-temperature, and clean environment necessary to precisely manipulate these material properties, making it an indispensable tool in both battery research and manufacturing.

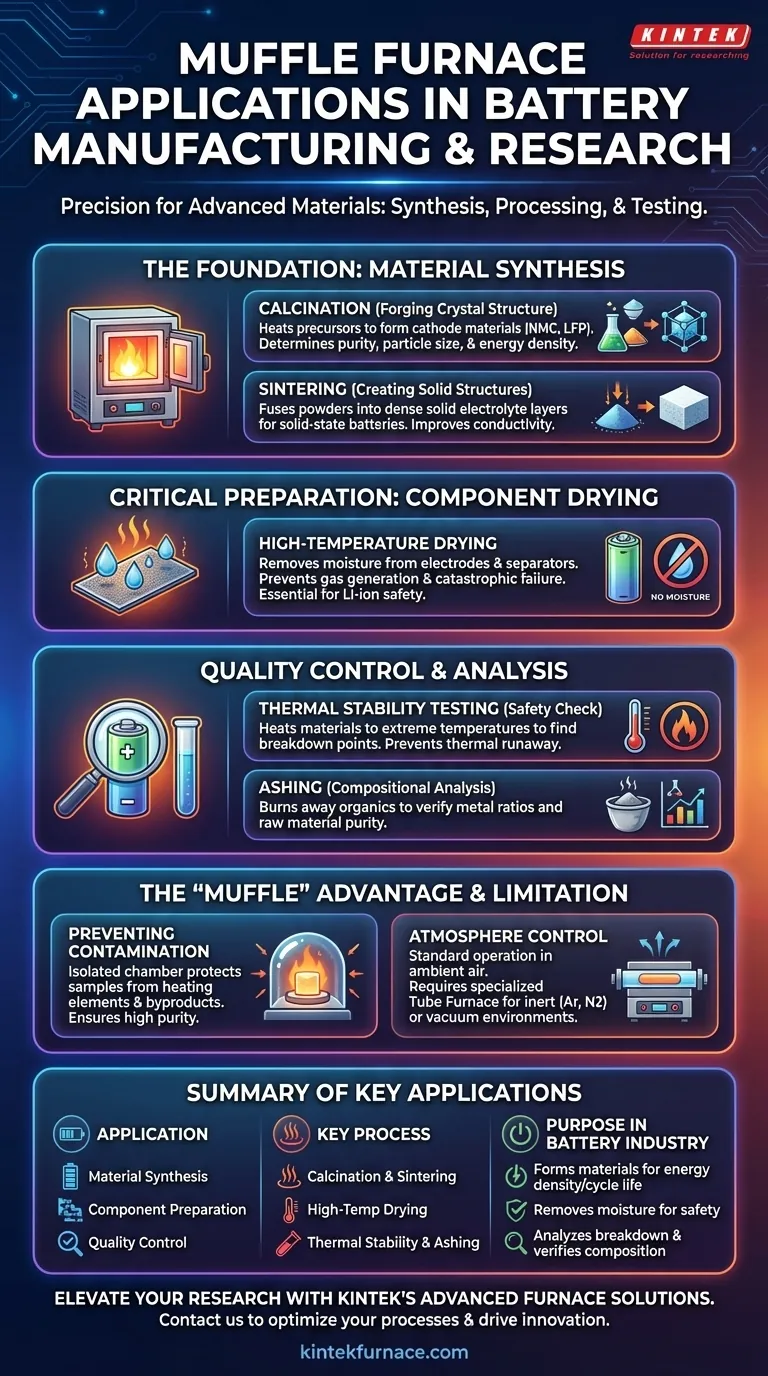

The Foundation: Synthesizing Advanced Battery Materials

The creation of active battery materials is a process of high-temperature chemical transformation. A muffle furnace provides the precise thermal environment required to forge these materials from simpler precursor chemicals.

Calcination: Forging the Crystal Structure

Calcination is a heat treatment process that induces chemical reactions and phase changes. In battery manufacturing, it is used to heat a mixture of precursor powders (like lithium, nickel, and cobalt compounds) to form the desired crystalline structure of the final cathode material, such as NMC (Nickel Manganese Cobalt Oxide) or LFP (Lithium Iron Phosphate).

The exact temperature and duration of this process determine the material's purity, particle size, and crystal integrity—all of which directly impact the battery's energy density and cycle life.

Sintering: Creating Solid Structures

Sintering uses heat to fuse powders into a solid, dense mass without melting them. This is critical in the development of next-generation solid-state batteries, where sintering is used to create dense ceramic electrolyte layers.

It is also used to increase the density and conductivity of electrode powders, improving the overall performance of the battery cell.

Critical Preparation for Cell Assembly

Even after materials are synthesized, they must be meticulously prepared before being assembled into a battery cell. Moisture is the enemy of most battery chemistries, especially lithium-ion.

High-Temperature Drying

Electrodes, separators, and electrolytes must be completely free of residual water and solvents before cell assembly. Even trace amounts of moisture can react with the electrolyte, leading to gas generation, rapid degradation, and catastrophic cell failure.

A muffle furnace provides a stable, high-temperature environment to aggressively dry these components, ensuring the long-term reliability and safety of the final battery.

Quality Control and Failure Analysis

Muffle furnaces are not just for creating materials; they are also essential for testing and analyzing them. This ensures materials meet strict specifications and helps researchers understand why a battery may have failed.

Thermal Stability Testing

A key safety concern for batteries is thermal runaway. Muffle furnaces are used to heat battery materials and components to extreme temperatures under controlled conditions. This testing reveals the temperature at which materials begin to break down, helping engineers design safer batteries and predict their behavior under abuse conditions.

Ashing for Compositional Analysis

Ashing is a process where a sample is heated at high temperature to burn away all its organic and volatile components, leaving only the inorganic, non-combustible material (ash).

In the battery industry, this is used to verify the precise ratio of metals in a cathode material or to determine the purity of raw materials. It is a fundamental quality control step that confirms the material's chemical identity.

Understanding the Trade-offs

While incredibly useful, it's important to understand what makes a muffle furnace the right—or sometimes wrong—tool for a specific battery application.

The "Muffle" Advantage: Preventing Contamination

The defining feature of a muffle furnace is the muffle, a chamber (often ceramic) that isolates the sample from the heating elements and any combustion byproducts. This separation is crucial for synthesizing high-purity battery materials, as direct contact with heating elements could introduce contaminants that degrade performance.

Limitations: Atmosphere Control

A standard muffle furnace operates in ambient air. However, many advanced battery material synthesis processes require an inert atmosphere (like argon or nitrogen) or a vacuum to prevent unwanted oxidation. For these applications, a more specialized tube furnace is the appropriate choice.

Matching the Furnace to Your Battery Application

Choosing the right equipment depends entirely on your goal.

- If your primary focus is R&D and material synthesis: You need a furnace with precise temperature control and programmable heating/cooling rates to develop novel cathode or anode formulations.

- If your primary focus is quality control and analysis: A furnace optimized for repeatable, stable heating cycles for ashing and thermal stability tests is essential for reliable data.

- If your primary focus is pilot-scale production: Look for larger-capacity batch furnaces for drying electrodes and preparing bulk quantities of synthesized materials.

Ultimately, the muffle furnace is an indispensable tool, shaping the very chemistry that powers our future.

Summary Table:

| Application | Key Process | Purpose in Battery Industry |

|---|---|---|

| Material Synthesis | Calcination & Sintering | Forms cathode/anode materials and solid-state electrolytes for energy density and cycle life |

| Component Preparation | High-Temperature Drying | Removes moisture to prevent degradation and ensure battery safety |

| Quality Control | Thermal Stability Testing & Ashing | Analyzes material breakdown and verifies composition for reliability |

Elevate your battery research and production with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide muffle, tube, rotary, vacuum, and atmosphere furnaces, along with CVD/PECVD systems. Our deep customization capability ensures precise solutions for your unique experimental needs, from material synthesis to quality control. Contact us today to discuss how our expertise can optimize your processes and drive innovation in your lab!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization