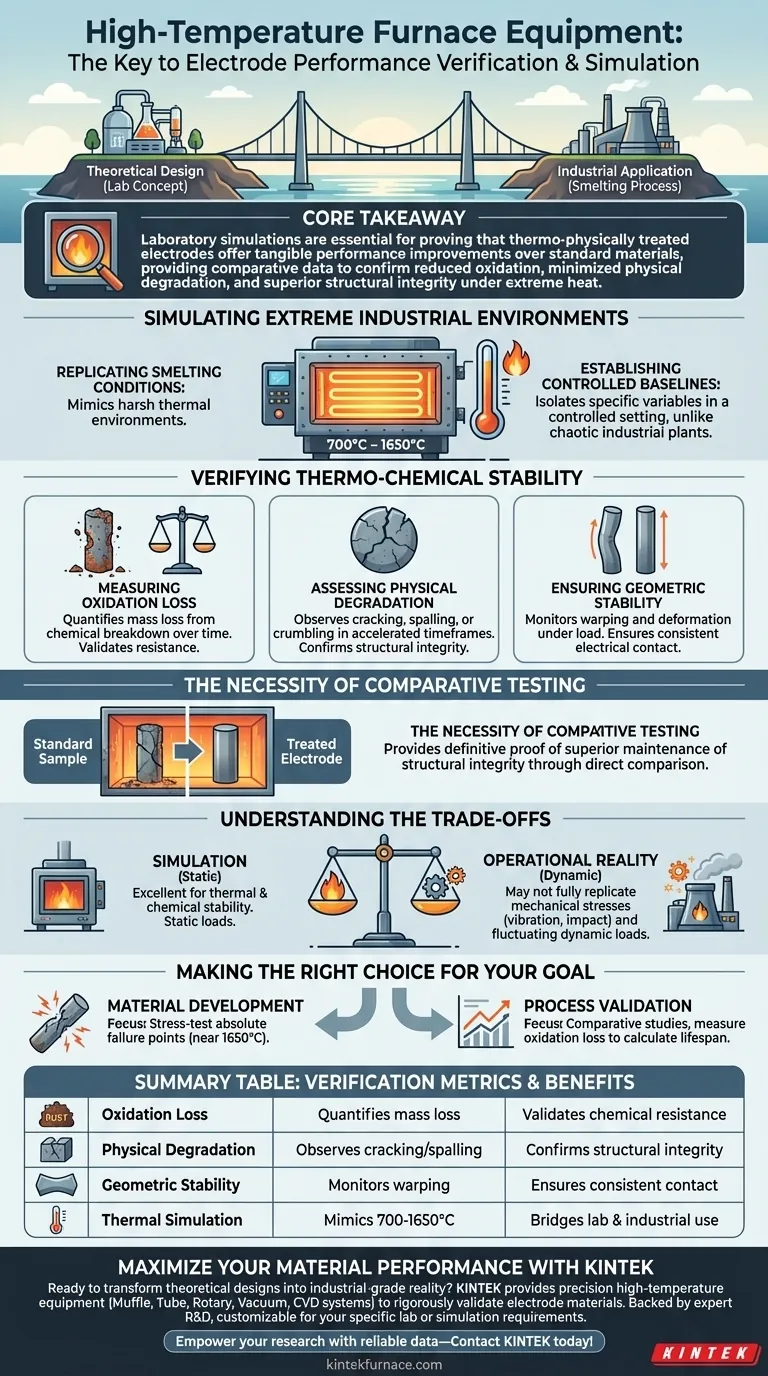

High-temperature furnace equipment acts as the critical validation stage in the development of electrode materials, bridging the gap between theoretical design and industrial application. By generating precise temperatures ranging from 700°C to 1650°C, these laboratory-grade units simulate the harsh thermal environments of smelting processes to rigorously test the thermo-chemical stability and physical resilience of modified electrodes.

Core Takeaway Laboratory simulations are essential for proving that thermo-physically treated electrodes offer tangible performance improvements over standard materials. These furnaces provide the comparative data necessary to confirm reduced oxidation, minimized physical degradation, and superior structural integrity under extreme heat.

Simulating Extreme Industrial Environments

Replicating Smelting Conditions

To accurately predict how an electrode will perform in a real-world foundry, testing must occur under similar thermal stress.

Laboratory-grade furnaces are capable of reaching temperatures between 700°C and 1650°C.

This broad range allows researchers to mimic the specific extreme thermal environments found in various smelting processes.

Establishing Controlled Baselines

Unlike the chaotic environment of an active industrial plant, a laboratory furnace offers a controlled setting.

This allows for the isolation of specific variables, ensuring that performance data is attributed strictly to the material properties of the electrode.

Verifying Thermo-Chemical Stability

Measuring Oxidation Loss

One of the primary failure modes for electrodes in high heat is oxidation.

High-temperature furnaces allow researchers to quantify exactly how much mass an electrode loses due to oxidation when exposed to heat over time.

This validates whether modified materials successfully resist chemical breakdown better than untreated counterparts.

Assessing Physical Degradation

Heat causes materials to crack, spall, or crumble.

Simulation testing provides a window to observe physical degradation in accelerated timeframes.

If a treated electrode remains intact while a control sample degrades, the efficacy of the treatment is verified.

Ensuring Geometric Stability

An electrode must maintain its shape to function correctly in an arc furnace or smelting pot.

Testing verifies geometric stability, ensuring the material does not warp or deform under thermal load.

This confirms that the electrode will maintain the necessary electrical and physical contact points during actual operation.

The Necessity of Comparative Testing

Validating Thermo-Physical Treatments

The primary goal of using this equipment is often comparative analysis.

Researchers place thermo-physically treated electrodes alongside standard samples to observe relative performance.

The equipment provides definitive proof of whether the modification results in superior maintenance of the electrode's structural integrity.

Understanding the Trade-offs

Simulation vs. Operational Reality

While high-temperature furnaces are excellent for testing thermal and chemical stability, they are simulations.

They may not perfectly replicate dynamic mechanical stresses, such as vibration or physical impact, present in an active industrial smelter.

Static vs. Dynamic Loads

Furnace testing is typically a static thermal load.

Real-world applications often involve fluctuating electrical currents and dynamic interactions with slag or raw materials, which pure thermal simulation might not fully capture.

Making the Right Choice for Your Goal

How to Apply This to Your Project

- If your primary focus is Material Development: Prioritize testing at the upper limits (near 1650°C) to stress-test the absolute failure points of your modified coatings or treatments.

- If your primary focus is Process Validation: Use the furnace to perform comparative studies, strictly measuring oxidation loss rates between treated and untreated samples to calculate potential lifespan improvements.

Ultimately, high-temperature simulation transforms theoretical material improvements into verified, quantifiable performance data.

Summary Table:

| Verification Metric | Testing Significance | Key Benefit |

|---|---|---|

| Oxidation Loss | Quantifies mass loss over time | Validates chemical resistance and durability |

| Physical Degradation | Observes cracking, spalling, or crumbling | Confirms structural integrity under stress |

| Geometric Stability | Monitors warping and deformation | Ensures consistent electrical contact |

| Thermal Simulation | Mimics 700°C to 1650°C environments | Bridges gap between lab and industrial use |

Maximize Your Material Performance with KINTEK

Ready to transform theoretical designs into industrial-grade reality? KINTEK provides the precision high-temperature equipment needed to rigorously validate your electrode materials. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific lab or simulation requirements. Whether you are focusing on material development at 1650°C or validating process stability, our furnaces deliver the controlled environments you need to succeed.

Empower your research with reliable data—Contact KINTEK today to discuss your project!

Visual Guide

References

- K. A. Krylov, V. M. Dydin. Thermophysical Treatment of Petroleum Coke-Based Electrode Paste as a New Promising Approach to Integrating the Oil Refining and Metallurgical Industries for Carbon-Graphite Electrode Production. DOI: 10.5829/ije.2026.39.02b.05

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is a box furnace? A Versatile Tool for Precise Heat Treatment

- How does a muffle furnace facilitate the slow pyrolysis process? Optimize Biochar Production from Organic Waste

- What is the function of a laboratory high-temperature furnace in cook-off synthesis? A Precise Thermal Initiator

- What is the role of a muffle furnace in the final formation of a composite photoanode? Master Heterojunction Synthesis

- What is the role of a high-temperature box furnace in coal gangue calcination? Unlock High Pozzolanic Activity

- Why is thermal treatment of kaolin in a muffle furnace required for preparing AAMs? Unlock High-Performance Binders

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does the use of a muffle furnace improve the ion exchange process in zeolites? Optimize Your Catalyst Performance